Progress in BRAKE DESIGN

Page 152

Page 153

Page 154

If you've noticed an error in this article please click here to report it so we can fix it.

A Review of Many Types of Leverassisted Brake and Power Brake Which Are to be Seen on Presentday Commercial Motors

AFACT that will be impressed upon the minds of visitors to the Olympia Show with increasing force as they examine, one after another, the many new examples of passenger and goods chassis is that designers are coming to a realization of the great power that is needed to brake, practically to the point of locking, the wheels of a fast and heavy commercial vehicle. We say to the point of locking, because that is the limit of possible braking efficiency, and we mean it, of course, in connection with a dry road surface which affords good adhesion.

Better Brakes Indispensable.

Whether designers did or did not appreciate the degree of power needed, the fact is that in the past commercial vehicles have not been equipped with braking gear that was capable of such power of retardation except by employing excessive manual effort. In point of fact, they did not require it ; they travelled at speeds which were low enough to render adequate retardation possible with lower braking effictency.

Now, with more efficient power mins and pneumatic-tyre equipment, heavy loads can be carried with silence and stability at very much greater speeds. Such speeds are perfectly safe, provided that the braking be correspondingly powerful.

One could profitably spend a whole day studying the various forms of brake equipment which will be shown at Olympia. What great advances are being made! Where the physical effort of the driver is relied upon the designer has turned to increased leverage and a simple lay-out as means for obtaining the power needed.

Robey rigid six-wheeled steam wagon (which, unfortunately, will not be seen at Olympia) has equipped all four driving wheels with drums of 2 ft. 61 ins., diameter and 3 ins, effective width. On the new Karrier tractor-trailer outfit very big brake drums are a noticeable feature, and they are well ventilated. There is a distinct tendency in this direction—a tendency that is welcome.

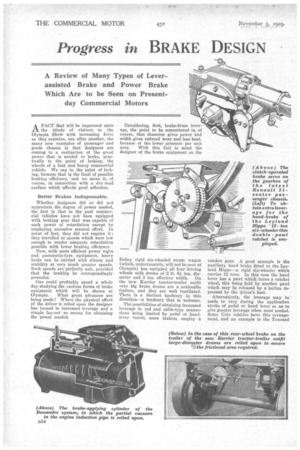

The possibilities of obtaining increased leverage in rod and cable-type connections being limited by pedal or handlever travel, some makers employ a ratchet gear. A good example is the auxiliary hand brake fitted to tho.Leyland Hippo—a rigid six-wheeler which carries 12 tons. In this case the hand lever has a pawl which turns a ratchet wheel, this being held by another pawl which may be released by a button depressed by the driver's heel.

Alternatively, the leverage may be made to vary during the application stroke of pedal or hand lever so as to give greater leverage when most needed. Some Unic vehicles have this arrangement, and an example is the Tourand brake gear marketed in England by the Houdaille Hydraulic Suspension Co., Ltd.

Apart from the leverage method of obtaining retarding power there is the self-energizing type of mechanism, which, if binding and irregular and unbalanced action can be prevented, is capable of satisfactory results. A brake of this kind that will be seen at Olympia is the Bendix, in which the application of one shoe is effected by the driver, the friction between this shoe and the drum being relied upon to force another shoe or shoes into operation. Chassis of International, G.M.C., Stewart, and Citroen makes, among others, have this kind of brake.

Visitors to Olympia should not fail to inspect the clutch-operated servo brake on the Renault chassis, also the interesting Berliet system.

Transmission Brakes.

Some desiguers place their faith in the transmission brake, because it gives them the advantage of the back-axle ratio, this multiplying the brake-shoe power by seven, eight, nine, or more, as the case may be. There is the disadvantage of the heat generated by so great a retardation effort over BO small a brake-facing area, and the objection of stress on transmission gear. As an emergency brake, however, it is powerful, and some good examples are to be seen employing big drums. The new Scammell 6-ton lorry has a transmission brake of 16-in, diameter and 31-in.

width. On the Minerva and B.A.T. a brake of the same type is located on the pinion shaft of the spiral-bevel rearaxle drive, thus relieving the propeller shaft of braking stress.

Excepting the transmission brake all the types referred to previously depend upon rods (or cables) and levers for their actuation. Efforts to remove the objections of mechanical actuation have been made; for example' interference in cross-shaft movement by reason of chassis distortiOn is reduced by spherical bearings, as on Guy, Dennis, and other chassis, or by self-aligning bearings of the kind used in the Claytini. cross-shaft When we come to the abolishing of all rods and joints, however,. we open up a new and wide field of possible advancement. Leaving power brakes unconsidered for the moment, we find a good example in the Lockheed hydraulic brake, which will be seen on Dodge Brothers, Rem and many other machines—especially the Americans. The driver's pedal forces a small plunger into a cylinder, thus driving oil through pipes into a larger cylinder inside each brake dram, forcing apart two pistons which press the shoes against the drum. Hydraulic leverage is effective, although limited by pedal travel, and it has the advantages of simplicity and balanced braking between the road wheels, so that for vehicles of moderate weight there is much to commend it.

This brings us to the consideration of power brakes, the importance of which varies directly with the weight anti speed of each vehicle.

• Engine compression is utilized with success on some Continental makes, the valve action being suitably altered by sliding the camshaft. Examples of this type will be seen at Olympia in the Berna vehicles shown by Lawson Pigott Motors and in the impressive Snares Machines.

Induction-pipe VACUUM is the force employed at present in most makes of power brake, not that this necessarily points to its Superiority in every respect. The Dewandre system (which will be demonstrated on Stand 187) is fitted to private and commercial chassis by many British and Continental makers, and it can be seen on Leyland, Guy, Vulcan, A.E.C. and numerous other chassis. About 11 lb. per sq. in. negative pressure is available in the induction system when the throttle is nearly closed. The maximum power at the Dewandre cylinder is easily calculated, being approximately IrT2 multiplied by 11, and this can be increased by employing more than one cylinder, as on the Leyland Hippo 12-ton six-wheeler, which has three. Brake rods and joints are not entirely dispensed with.

Vacuum-storage Systems.

So that power may be available for several brake applicathins although the engine be stopped, a vacuum-storage cylinder is incorporated in some airbrake systems, notably the Westinghouse and C.B.E. Vaeuttm-Uniped makes, which will, be demonstrated on stands 149 and 151 respectively. These exhibits should certainly not be overlooked. In the former case an ingenious valve automatically connects either the storage cylinder or the induction pipe to the brake cylinder, according to which holds the greater degree of vacuum. In the latter case the reservoir is connected to the induction system a non-return ball valve being interposed in the pipe. The Uniped valve, by which the driver controls brake application, is a clever piece of mechanism. Whilst the Westinghouse system employs a cylinder and piston the C.B.E. brake makes use of

a rubber-fabric diaphragm, one for each road wheel. As with the Dewandre brake, rods and joints are used in both these systems. A good example of Westinghouse brake with multiple cylinders will be seen on the Bristol sixwheeler.

Worthy of mention as suitable for the lighter commercial vehicles is the Marelli vacuum brake, marketed by Morelli Magnetos (England), Ltd. It was exhibited two weeks ago at the Motor Show at Olympia, but may not be available at the Commercial Motor Exhibition, The extra power is available when the engine is running and is applied by way of a collapsible rubber bellows. Simplicity, adaptability and cheapness make it interesting. It can be fitted to existing vehicles with very little alteration to the standard brakeoperating gear.

Compressed-air Brakes:

Another type of Westinghouse pneumatic brake is the positive-pressure system in which a compressor, driven by the engine, charges a storage cylinder which applies the brakes through the medium of diaphragms. This is to be seen on the new Karrier tractor-trailer

outfit. The trailer brake is automatically applied should the trailer part company from the tractor.

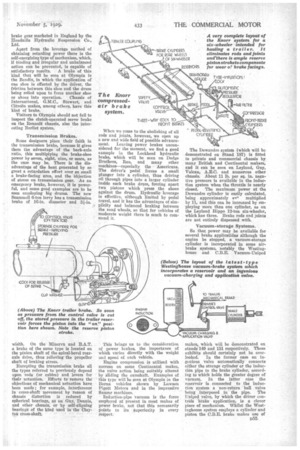

A compressed-air system which aims at the elimination of all brake rods and joints is the Knorr, made by a wellknown German concern. In this case a small cyrinder is fitted to each brake cover and the piston rod directly actuates the cam lever. An important feature is that there is ample reserve movement to compensate for wear of the brake facings, adjustment being un

E-ec-C"§-arY. _Another point is that the compressor offers a load on the engine only when the pressure in the reservoir is reduced, for wheu normal pre sure is reached a valve automatically by-passes the compressor output to waste.

The working pressure is high and the compressor of ample size, so that should there be slight leakage the braking remains unimpaired. The power available is, of coarse, sufficient, practically speaking, to skid any wheel under any load, and the application is delightfully smooth and perfectly controlled. The brake will be seen at Olympia on the Chenard-Walcker tractor-trailer outfit on stand No. 122, where it should certainly be inspected. The arrangement for automatically applying the trailer brake on the parting of tractor and trailer is most ingenious.