Recent Developments in

Page 122

Page 123

Page 124

If you've noticed an error in this article please click here to report it so we can fix it.

PASSENGER-VEHICLE

BODYWORK

Some Notes Upon the Progress which has been Made During the Past Few Years in the Construction of All Classes of Coach and Bus, Together with a Forecast of New Fashions.

Tkt dominating factor in the design of passenger-vehicle bodywork is the provision of a comfortable seat for every person. The seat of the service bus may not be as luxurious as that of a long-distance coach, but, taking into consideration the class of traffic which has to be dealt with, no effort is spared to design the seat so that its qualities of durability shall not impair its efficiency.

It is now fully recognized that the spacing of the seats is of first importance and that a cramped position does not compensate for any extra depth of cushion, or height of back rest. Little can be done to improve the crosswise seat, so as to provide more length per passenger, because any increase in length reduces the central gangway. The best compromise is the individual shaping of the seat back.

The rigid seat back is more popular than is the pattern which is made up on spring steel supports. The latter type of hack gives resilience in a most compact form and is ideal for intermediate rows of seats, but if such a seat be mounted next to a bulkhead or partition, or at the end of a long seat, space must be left for the full amount of deflection of the spring-steel back.

The rigid back can be made to provide various degrees of comfort by adding a pad of upholstery, a few inches deep, to the full-depth squab, whilst further luxury is afforded by the insertion of coil springs

D24 or pneumatic foundations.

Much use is made nowadays of sheet-metal and pressings for improving the construction of the seat. By this means weight is reduced and more space is left for the disposal of the upholstery, whilst the pressed-steel seat support has a smooth exterior which can be easily cleaned.

The manufacture of seats and their component parts has now become an important industry. Every bodybuilder may avail himself of this specialized experience, whic h, if taken full advantage of, has the effect of maintaining to a high degree the standard of comfort which is provided by the passenger vehicle.

The typical material of construction for the body is still hardwood, this being well reinforced by metal plates. The bottom sheet-metal bracket, which strengthens the lower corners at the point at which the side pillars join the ends of the crossbars, continues to be one of the most vital features of the body framework. It has reduced the necessity of using any large section of timber for the bottom side or main sill of the side framework.

Although with crossbars of sufficient substance, and well-designed lower brackets, a body which is twice the width of the chassis may be well supported, it is considered that the proper mounting of the body demands the provision of a full set of outrigger brackets, designed by the engineer, as part of the normal construction of the passenger chassis.

The bodybuilder finds little encouragement to introduce any high degree of standardization into his products. Many of the more important items, such as pillars, hoopsticks, body irons, seats and their equipment, doors and door gear, may be so designed as to be easily adapted to different widths, heights and lengths of body and numbers and arrangements of entrance, but the body, as a whole, is still more or less a special design for each customer and is modified, as necessary, for the particular dimensions of the chassis concerned.

The bodybuilder who specializes in commercialmotor bodies cannot anticipate a season's demand, by constructing complete bodies, in the same way that is possible in the privatecar industry. To a certain extent, this may explain why the production of the all-metal body does not rapidly expand, but, at the same time, 'there is far more scope than at present obtains for a built-up metal form of construction, or the introduction of more sheet-metal parts, or pressings, into a composite form of framework and panelling.

The fabric-panelled body has .not yet attained wide notice for public-service work. As a means for exterior finish, fabric has recently enjoyed a considerable amount of publicity, owing to the fact that, at the Paris Motor Show, the Weymann bodies were metal-panelled. It has since transpired that the French house was only adapting itself to the fashion of the moment, whilst the British Weymann body, as exhibited at Olympia, proved that no alteration in policy, even temporary, was contemplated, owing to the demand for the fabric body being not only maintained, but increased. The coach proprietor should, therefore, not overlook this means for lending an attractive effect to his vehicle, whilst many may wish to compromise and make use of this form of covering for the upper parts of the body, including the pillars above the waist line.

Regarding the general design of the single-decker there have been no radical changes, but detail improvements have been effected, chiefly with the forwardcontrol type of bus, accommodating 30, or more, passengers.

The modern forward cabin has a sloping screen, and D25 Much attention has been devoted • to shaping the roof, so that the destination indicator is neatly incorporated. Glass louvres above the main drop windows have, practically, been standardized and no single-decker is considered to be complete without two or more efficient air extractors situated in the roof.

The emergency door is still retained for the frontentrance single-decker, but it is being recognized that an exit, in ease of fire, is of less use than is a properly designed entrance or exit which may be used under all conditions of service for expediting loading and unloading. The number of entrances in the near future, it is thought, will be determined, not by the position of the main entrance, but by the seating capacity of the vehicle, and the next development which may be confidently expected is the general-provision of second staircases to double-deckers.

Development of the-Long-distance Coach.

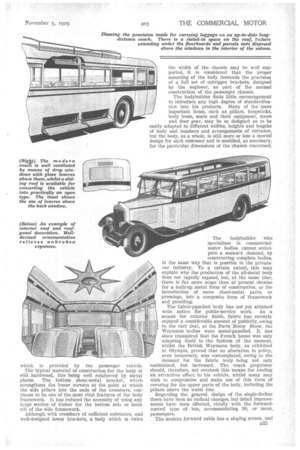

Long-distance coaches have increased considerably in numbers dtiring the -past two years and they are developing chiefly on the lines of high-class express: buses, buses, with space provided for luggage, rather-than as public caravans-de-luxe with buffet and lavatory compartments. The storage space represented by the lockers at the side of the chassis, formed by extending the .panelling downward to the step level, is not always used as an alternative to loading the roof or stowing the luggage inside the body, but is often employed as an addition to such luggage accommodation. The special roof locker has not been adopted to any great extent.

It . would appear that if the sleeper-coach is to be further developed it must be as a convertible day-andnight vehicle, the latter function being an emergency rather than its main feature.

The all-weather coach, with its opening roof, has during the past year increased in popularity. The typical coach has a fixed rear portion which may not only •facilitate the concealment of the opening part of the roof, but also provide a space for luggage. As opening roofs are in some cases used for single-deck buses, it is probably only a question of time before they are adopted for the double-decker.

Progress of the Double-saloon Bus.

The covered-top double-decker has made steady progress since it received the approval of the London authorities. Although the latest type to be introduced. it will, in the long run, prove'to be the most powerful factor in deciding the form of traction which is in the future to be employed in our large cities and towns. The improvement of the upper deck by shielding it from the rain and wind, and by adding cushions to the seats, has been followed by a reduction of overall height and ingenious arrangements of seating. In this way not only is headroom economized, but staircases are made less steep and safer to negotiate. Now mounted upon six pneumatic-tyred wheels, the fullcapacity covered-top double-decker needs only, as already indicated, a second staircase in order to complete its efficiency.

Regarding details of the upper saloon. it is usually more efficiently ventilated than in the case•of the lower compartment. The front windows and louvres are used to best advantage when no route indicator is allowed to obstruct them. The roof is now usually devoid of interior hoopsticks or ribs. Any •cro-bracings that are required to stiffen the metal arch of the roof are fastened outside, so that they affect only slightly the overall height and allow the maximum .1.fflount of internal headroom to be provided.

An increasing number of covered-top double-deckers is being provided with enclosed staircases, and in a year or two the open staircase for a new vehicle will probably be regarded as old-fashioned.