road and workshop

Page 46

If you've noticed an error in this article please click here to report it so we can fix it.

by Handyman

Auto-electrics for the mechanic (18)

THIS WEEK I want to go further into the care of the alkaline battery and in particular the electrolyte. Separate utensils and hydrometers should be kept for the alkaline cell; on no account should an hydrometer, filler bulb and tube be used that has been dealing with lead acid batteries. The cell filler caps should always be kept closed except when testing or topping up, and as the gas from alkaline cells is explosive it should be obvious that no naked flame must be allowed near open cells.

Regarding well used batteries and surface erosion of the cells, this can best be treated in the following manner. First, fit the original rubber plugs supplied with the battery when new; spare plugs can be obtained from the agents if the originals are missing — these plugs prevent any splashing or spillage as it will be necessary to upturn the battery for bottom attention and the plugs make it unnecessary to drain the cells.

Protective paint Normally, the cells are coated with a protective bitumastic paint, and this can best be removed by using naphtha applied with a brush. The cell under treatment should then be thoroughly cleaned and dried off. The corroded area can then be tackled with a wire brush and should be scrubbed until all traces of erosion are removed.

Once this area is satisfactorily scrubbed bright and clean, it is then necessary to again treat the cell with bitumastic paint and this is rather a slow job — at least as I remember it — as to do the job satisfactorily, three separate coats are necessary and the drying time between coats is something like 12 hours. When completely dry the rubber plugs can be removed and the caps closed.

It pays to paint the whole of the cell, bottom and sides, at the time this work is undertaken and not just the area particularly affected, as the battery is then fit for a long period of service.

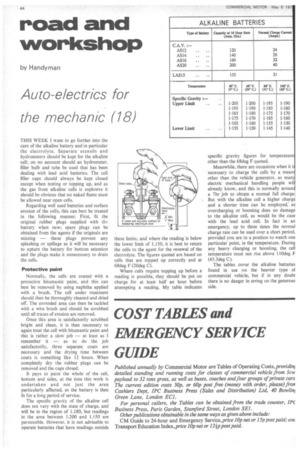

The specific gravity of the alkaline cell does not vary with the state of charge, and will be in the region of 1.180, but readings in the area between 1.200 and 1.150 are permissible. However, it is not advisable to operate batteries that have readings outside these limits, and where the reading is below the lower limit of 1.150, it is best to return the cells to the agent for the renewal of the electrolyte. The figures quoted are based on cells that are topped up correctly and at 68deg F (20deg C).

Where cells require topping up before a reading is possible, they should be put on charge for at least half an hour before attempting a reading. My table indicates specific gravity figures for temperatures

other than the 68deg F quoted.

Meanwhile, there are occasions when it is necessary to charge the cells by a means other than the vehicle generator, as many electric mechanical handling people wil.

already know, and this is normally around a 7hr job to obtain a normal full charge But with the alkaline cell a higher charg and a shorter time can be employed: as overcharging or boosting does no damage to the alkaline cell, as would be the case with the lead acid cell. In fact in an

charge rate can be used over a short period, provided you are in a position to watch one particular point, ie the temperature. During any heavy charging or boosting, the cell temperature must not rise above 110deg F (43.3deg C).

The tables cover the alkaline batteries found in use on the heavier type of commercial vehicle, but if in any doubt there is no danger in erring on the generous side.