xhaust rakes lave their 'onus )(Ants

Page 31

Page 32

If you've noticed an error in this article please click here to report it so we can fix it.

v Gibb Grace

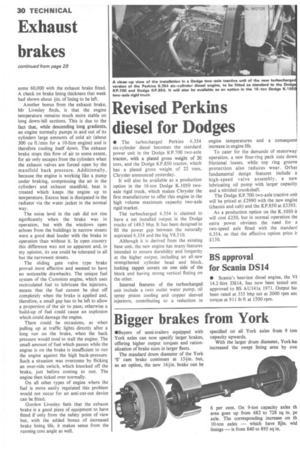

Exhaust brakes are fitted as standard plipment on almost all heavy overseas ;hicks yet they are virtually unknown in is country. To some extent their failure to ttch on here reflects experiences of the irly types which were first introduced into )aches. The passing of time has produced any changes and new types of brake, one the most significant being the sliding gate he type made by the Australian company niths Exhaust Brakes and sold in this

■ untry by Exhaust Brake Sales and ;rvice Ltd, 1593 London Road, Norbury, midon, SW16, (CM October 11971). The ost important difference between this haust brake and others is that, in place of hinged butterfly valve to block off haust, it has a sliding shutter.

To get operational experience of the ding gate valve type of exhaust brake cently accompanied Gordon Livesley — a )rkshire operator running three ERFs a normal haulage run over the Pennines. le ERFs haul steel strip from the mills in iddlesbrough to a steel stock warehouse Bolton, with return loads of cut sheets for stomers in Yorkshire. We pulled out of e warehouse with a gross weight of 31 ns 5cwt bound for Newcastle. Our route er A59 was twisting with a series of steep s and downs.

What impressed me immediately was how quickly up-changes were made. The engine, a 220 Cummins, died down more quickly than normal thus making the changes easier and this, it seems, is a bonus that few people expect, least of all the driver. The reason for the shorter die-down period was that control of the exhaust brake, as fitted to that ERE, was operated directly via the throttle and not by a separate heel button as is often the case with foreign vehicles. Consequently, as soon as the accelerator foot was lifted the brake came in and slowed the engine down. Once the change was made and the accelerator pedal pushed down again the brake cleared with a sharp snap. So marked was this improvement in up-changing time that on some sections of the route the ERF was often running in a higher gear than would otherwise have been possible. The driver agreed that this could lead to shorter journey times and possibly better fuel

consumption unfortunately, he had no figures to prove the point.

Linked as it was to the accelerator, the exhaust brake came into operation immediately the accelerator foot was lifted. This meant that it was used on all down-hill sections and not just when the driver remembered. Most exhaust brake buttons are placed where they can be operated by the heel of the clutch foot and, at best, there is a delay from taking the right foot off the accelerator and putting the left foot where the heel can operate the button. The throttle-linked brake removes this time lag and reacts much quicker than non-automatic operation.

The Cummins engine was not fitted with special, stiffer than normal, exhaust valve springs and yet the braking effect was considerable. It will be appreciated that engine speed is important — the greater the engine speed the greater the braking effect generated. Using the brake, most hills could be safely descended in one or even two gears higher than would have been possible without it. Although the speeds were higher, the service brakes were not always used, thereby keeping them cool. In cases where the exhaust brake alone would not hold the vehicle on a gradient at a steady speed, momentary use of the service brakes brought the vehicle under control. Lessened use of the service brakes leads, of course, to longer life of the linings, though there is no hard and fast rule as to how much more since a great deal depends on the routes over which a vehicle runs. Mr Livesley's ERF has completed about 90,000 miles,

some 60,000 with the exhaust brake fitted. A check on brake lining thickness that week had shown about +in. of lining to be left.

Another bonus from the exhaust brake, Mr Livesley finds, is that the engine temperature remains much more stable on long down-hill sections. This is due to the fact that, while descending long gradients, an engine normally pumps in and out of its cylinders large amounts of cold air (about 300 Cu ft /min for a 10-litre engine) and is therefore cooling itself down. The exhaust brake stops this flow of air to some extent, for air only escapes from the cylinders when the exhaust valves are forced open by the manifold back pressure. Additionally, because the engine is working like a pump under braking, compressing the air in the cylinders and exhaust manifold, heat is created which keeps the engine up to temperature. Excess heat is dissipated in the radiator via the water jacket in the normal way.

The noise level in the cab did not rise significantly when the brake was in operation, but with the windows open echoes from the buildings in narrow streets were a good deal louder with the brake in operation than without it. In open country this difference was not so apparent and, in my opinion, its use could be tolerated in all but the narrowest streets.

The sliding gate valve type brake proved most effective and seemed to have no noticeable drawbacks. The unique fuel system of the Cummins engine, which uses recirculated fuel to lubricate the injectors, means that the fuel cannot be shut off cornpletely when the brake is applied and, therefore, a small gap has to be left to allow a proportion of the air to pass; otherwise a build-up of fuel could cause an explosion which could damage the engine.

There could be occasions, as when pulling up at traffic lights directly after a long run on the brake, when the back pressure would tend to stall the engine. The small amount of fuel which passes while the engine is on the brake is insufficient to run the engine against the high back-pressure. Such a situation was overcome by flicking an over-ride switch, which knocked off the brake, just before coming to rest. The engine then ticked over normally.

On all other types of engine where the fuel is more easily regulated this problem would not occur for an anti-cut-out device can be fitted.

Gordon Livesley feels that the exhaust brake is a good piece of equipment to have fitted if only from the safety point of view but, with the added bonus of increased brake lining life, it makes sense from the running cost angle as well.