A Swivelling Stand for Engine Repairs.

Page 13

If you've noticed an error in this article please click here to report it so we can fix it.

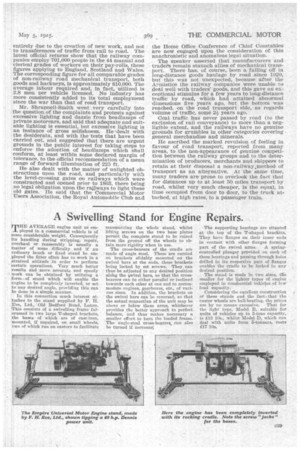

MHE AVERAGE engine unit as em ployed in a commercial vehicle is of some considerable weight. Consequently its handling during stripping, repair, overhaul or reassembly is usually a matter of some difficulty and if an ordinary bench or fixed stand be employed the fitter often has to work in a strained attitude in order to perform certain operations. Very much better results and more accurate and speedy work can be obtained by utilizing a form of stand which will enable the engine to be completely inverted, or set to any desired angle, providing this can be done in a simple manner.

In this connection much interest attaches to the stand supplied by F. H. Eve, Ltd., Old Bedford Road, Luton. This consists of a swivelling frame fulcrumed in two large T-shaped brackets, the bases of which . are of cast-iron, mounted, if required, on small wheels, two of which run on castors to facilitate manceuvring the whole stand, whilst lifting screws on the two base plates permit the complete stand to be raised from the ground off the wheels to obtain more rigidity when in use.

The cross-bearers of the cradle are 'made of angle steel. These are carried on brackets slidably mounted on the swivel bars at the ends, these brackets being locked by set screws. They can thus be adjusted to any desired position .aloshg the swivel bars, so that the crossbearers can be either parallel or inclined towards each other at one end to accommodate engines, gearboxes, etc., of various sizes. In addition, the brackets on the swivel bars can be reversed, so that the actual connection of the unit may be above or below these arms, whichever provides the better approach to perfect balance, and thus makes necessary a smaller effort to turn the loaded frame. The angle-steel cross-bearers can also be turned if necessarf, The supporting bearings are situated at the top of the T-shaped brackets. They have flauges on their inner ends in contact with other flanges forming part .of the swivel arms. A springcontrolled plunger provided on each of these bearings and passing through holes drilled in its respective pair of flanges enables the cradle to be locked in any desired position.

The stand is Made in two sizes, the smaller for the lighter types of engine employed in comfuerdal vehicles of low load capacity.

Considering the excellent construction of these stands and the fact that the castor wheels are ball-bearing, the prices are by no means. excessive. That for the light type, Model B, suitable for units of vehicles up to 3-tons capacity, is £13 10s., whilst Model D, which can deal with units from 5-tonners, costs £17 10s.