WERE ON TO A THREE-WAY TIP

Page 42

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

continued from page

. at the heavier gross weights — the body on the 300PC is about 1 tonne heavier than the reartip equivalent.

Maintenance is roughly the same for both types of body and gear except that the spherical joints on the Romanazzi three-way tip design require lubrication at suitable intervals.

However, lubrication is quick and should take no longer than a few minutes during a vehicle's normal servicing schedule.

On the body side there are obviously more hinges and clips that require lubrication and are vulnerable to damage during arduous operation unless care is exercised.

Selecting the direction of tip is a simple mechanical process well within the grasp of any driver. The Romanazzi body is mounted on spherical couplings at each corner, and the underbody ram is located amidships.

To set the tipping direction the driver has only to slot two pins into two of the spherical couplings. For instance, for conventional rear-end tipping the pins are placed, one each, in the rear-most spherical joints. Inserting the pins virtually converts the coupling into a hinge, the tipping stresses being taken through the spherical joint.

With the pins inserted the body can then be tipped to the rear in the normal way.

Swopping from rear end to side tipping involves shifting one pin. To tip on the nearside, the offside rear pin is transferred to the nearside front coupling.

An across-body locking bar prevents the body from being tipped forward and discharging the load onto the cab. I was told that an in-built safety device prevents the body from being lifted should the pins be inadvertently engaged diagonally across the body.

All of the bodies tested were fitted with automatic release tailgates, which saved time when tipping. But it was necessary to alight from the cab to shut them; the gate is simply swung home with sufficient pressure for the gate catches to override the spring-loaded latches that lie along the bottom edge of the tailgate opening.

A useful feature on the 01V155 was that the body side-gates were fitted with check straps which could be used to drop the wall through 90deg • and hold it flush with the body floor for tipping away from the vehicle sides. With the sidewalls hinged down to the full IBOdeg the discharged load fell into the wheel-rims and ran beneath the vehicle.

The tipping controls fitted to the heavier Fiats were a refreshing change from the bulky two-lever systems we are used to. Tipping is air controlled from a small three-switch console which can be neatly fitted to the side of the driving seat or elsewhere. To engage the pto the clutch is pushed out and the "tip" switch thrown. The other switches are normal and slow return, On the Fiat 130NC the controls were on the driver's seat and it was easy to control offside and rear tipping from just beside the cab. Besco's chief executive Mr. D. Wilson said that an option is available for controls to be fitted at one or both sides of the vehicle to enable the driver to closely monitor the discharge.

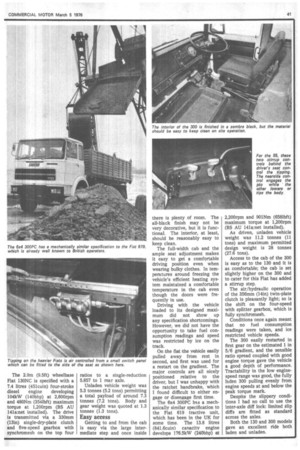

In stark contrast, the tipping controls in the small OMS5 were located behind the driver's seat and were both difficult and stiff to operate. Looking like two stirrup plungers sprouting from the floor, they restricted the rearward adjustment of the seat. The nearside lever is pressed firmly down to engage the pto, the offside one is either pushed down or withdrawn to lower or tip the body respectively. The 2.9m (9.5ft) wheelbase Fiat 130NC is specified with a 7.4 litres (451cuin) four-stroke diesel engine developing 104kW (140bhp) at 2,600rpm and 480Nm (3541bft) maximum torque at 1,200rpm (BS AU 141a:net installed). The drive is transmitted via a 330mm (13in) single-dry-plate clutch and five-speed gearbox with synchromesh on the top four ratios to a single-reduction 5.857 to 1 rear axle.

Unladen vehicle weight was 5.3 tonnes (5.2 tons) permitting a total payload of around 73 tonnes (7.2 tons). Body and gear weight was quoted at 1.3 tonnes (1.3 tons).

Easy access

Getting to and from the cab is easy via the large intermediate step and once inside there is plenty of room. The all-black finish may not be very decorative, but it is functional. The interior, at least, should be reasonably easy to keep clean.

The full-width cab and the ample seat adjustment makes it easy to get a comfortable driving position even when wearing bulky clothes. In temperatures around freezing the vehicle's efficient heating system maintained a comfortable temperature in the cab even though the doors were frequently in use.

Driving with the vehicle loaded to its designed maximum did not show up any specification shortcomings. However, we did not have the opportunity to take fuel consumption readings and speed was restricted by ice on the track.

On the flat 'the vehicle easily pulled away from rest in second, and first was used for a restart on the gradient. The major controls are all nicely positioned relative to the driver, but I was unhappy with the ratchet handbrake, which I found difficult to either engage or disengage first time.

The 6x4 300PC has a mechanically similar specification to the Fiat 619 tractive unit, which has been in the UK for some time. The 13.8 litres (841.6cuin) canacity engine develops 176.5kW (240bhp) at 2,200rpm and 901Nm (6581bft) maximum torque at 1,200rpm (BS AU 141a:net installed).

As driven, unladen vehicle weight was 11.2 tonnes (11 tons) and maximum permitted design weight is 28 tonnes (27.6 tons).

Access to the cab of the 300 is easy as to the 130 and it is as comfortable; the cab is set slightly higher on the 300 and to cater for this Fiat has added a stirrup step.

The air/hydraulic operation of the 356mm (14in) twin-plate clutch is pleasantly light; so is the shift on the four-speed with splitter gearbox, which is fully synchromesh.

Conditions once again meant that no fuel consumption readings were taken, and ice restricted vehicle speeds.

The 300 easily restarted in first gear on the estimated 1 in 5/6 gradient, and the sensible ratio spread coupled with good engine torque gave the vehicle a good depth of performance. Tractability in the low enginespeed range was good, the fully laden 300 pulling evenly from engine speeds at and below the peak torque mark.

Despite the slippery conditions I had no call to use the inter-axle diff lock: limited slip diffs are fitted as standard across the axles.

Both the 130 and 300 models gave an excellent ride both laden and unladen.