oft 4 THREE-WAY TIPPERS have some obvious operating advalogie tages over

Page 40

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

conventional rear' end models. A number of local councils have recognised their worth and are using them principally on highway maintenance. But hauliers in general seem reluctant to give them a try.

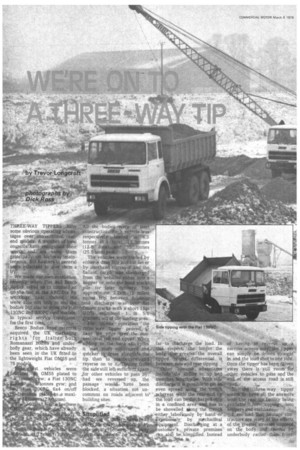

We made our own evaluation recently when Fiat and Besco Bodies asked us to conduct an on-site test at the ARC Dix Pit workings near Oxford. We were able not only to test the bodies but also to drive the Fiat 130NC and 300PC rigid models, in typical service conditions, for the first time.

Besco Bodies have recently acquired the UK marketing rights for Italian-built Romanazzi bolts and underbody gear, which have already been seen in the UK fitted to the lightweight Fiat 03455 and 75 st vehicles were 0111155 plated to w; a Fiat 130NC tonnes gvw; nd 00P 6x4 on/off 0.a maxiorts). elbase* th All the bodies were of steel onstruction. Each vehicle was respectively loaded to 6.5 tonnes 16.4 tons), 13 tonnes ( 1 2.8 tons) and 30 tonnes (25.5 tons) gvw.

The vehicles were loaded by either a drag line and bucket or by overhead conveyor and the ballast cargo was discharged from the vehicles either into a hopper or onto the bank stockpile for later delivery. The approximate 3.2km 12 miles) round trip between loadings and discharge was over flat frozen tracks with a short 1541 (50ft) estimated 1 in 5/6 gradient out, of the loading area.

For on-site operation the three-way tipper proved to have the edge over the conventional tail-end tipper. When adding to the bank stockpiles it was more convenient and quicker to. draw alongside the tip than to rnAm.teuvre and reyerse on to it. ping from the sine still left sufficient space for other vehicles to pass by; had we reversed up, the passage woulci., have been blocked, a situation not uncommon on roads adjacent to building sites.

_ or* — 444er far to discharge the load. In this respect, the longer the body the greater the overall tipped height differential is between side and rear tipping.

Other obvious advantages include the ability to tip into trenches lengthwise. With side discharge it is possible to get an even spread along the trench whereas with the rear-end tip the load can betischarged only ip a confined area and has to be shovelled Wiong the trench -.either laborktusly by hand or -vxpensivgly by mechanical quippient. DischAging at a ustorner's private premises alsO be ISimpiified. Instead Olt of having to reverse up a narrow access way; the tipper can simply be driven straight in and the load shot to one side. Once the tipper has been driven away there is still room for other vehicles to pass and the end of the access road is still open.

So the three-way tipper seems to have all the answers with the rear-tip facility being available for tipping into hoppers and suchlike.

I am told that haulage contractors are wary of the effects of the5. greater stresses imposed on the body and chassis by underbody rather than front mounted rams. They think that these stresses must lead to more frequent, servicing and repair. The eytra rrnetalrequired to strengthen the design does, of course, inevitably increase unladen weight and they think that this, in a threeway system, is not always worth the increased operational flexibility.

Romanazzi have been building three-way tipping systems since the war and their equipment is already well proven in Europe. Their 'system is heavier than rear-end ones, the smallest weight differential occurring at the lower vehicle weights. Obviously, the biggest potential for such equipment lies with light-weight tippers for local council and similar uses.

At the moment Besco is importing all-steel bodies; the option of aluminium will be availableiater.

Heavier

Compared to existing frontend tippers the underbody ram and body from Romanazzi comes out slightly heavier. The body and gear on tile 0M55 tips the scales at around 730g (14.4cwt), a comparable frontend assembly would weigh around 660kg (13cwt). The greater weight penalty comes

continued overleaf