New Steel Tipping Bodies

Page 38

If you've noticed an error in this article please click here to report it so we can fix it.

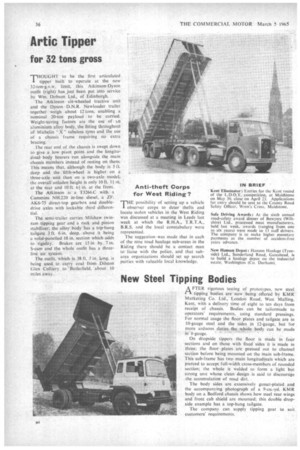

AFTER rigorous testing of prototypes, new steel tipping bodies are now being offered by KMR Marketing Co. Ltd., London Road, West Mailing, Kent, with a delivery time of eight to ten days from receipt of chassis. Bodies can be tailormade to operators' requirements, using standard pressings. For normal usage the floor plates and tailgate are in 10-gauge steel and the sides in .12-gauge, but for more arduous duties •the wbcile bpdy can be made in -8-gauge.

On dropside tippers the floor is made in fonr sections and on those with fixed sides it is Made in three; the floor plates are pressed out to channel section before being mounted on the Main sub-frame. This sub-frame has two main longitudinals which are pierced to accept full-width cross-members of rounded section; the whole is welded to form a light but strong unit whose clean design is said to discourage the accumulation of road dirt.

The body sides are extensively gusset-plated and the accompanying photograph of a 9-cu.-yd. KMR body on a Bedford chassis shows how steel rear wings and front cab shield are mounted; this double dropside example has a top-hung tailgate.

The company, can supply tipping gear to suit customers' requirements.