What the Industry Owes to Aluminium

Page 64

If you've noticed an error in this article please click here to report it so we can fix it.

A Wide Variety of Aluminium Alloys Available for Use in the Commercialvehicle Industry

rr HE range of light alloys available to the engineer to

day is extensive and, under the stimulus of aircraft development, it is likely that new alloys suitable also for use in the commercial-vehicle field will be produced. The efforts made to reduce weight have been, perhaps, the primary cause of the increasing use of aluminium in both goods and passenger machines. Nevertheless, this factor is not by any means the only one that has been responsible for the ready recognition of its all-round merits for a variety of purposes in our particular industry.

The ease with which aluminium alloys can be cast and fettled is well known, and the lightness of such castings facilitates handling and transport. Some alloys are easily forged, and heat-treated. The latter effects a remarkable improvement in their properties.

Pressings are being increasingly employed in chassis and body construction and, in this field, too, the ductility of aluminium lends itself admirably to this class of work. Complex parts can be pressed in this material, often without the need for intermediate anneals, and the surface smoothness of aluminium reduces the cost of finishing.

Reducing ,Machining Costs.

Certain alloys are also amenable to the die-casting process. The castings so produced possess better mechanical properties and a high degree of accuracy, thus reducing machining costs to the minimum.

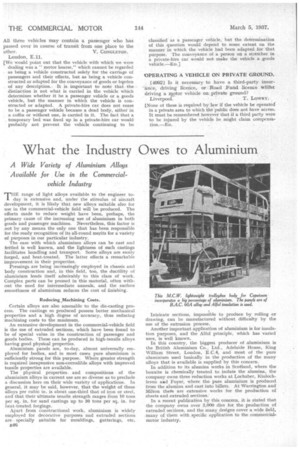

An extensive-development in the commercial-vehicle field is the use of extruded sections, which have been found to be of special value in the construction of passenger and goods bodies. These can be produced in high-tensile alloys having good physical properties.

Aluminium panels are, to-day, almost universally employed for bodies, and in most cases pure aluminium is sufficiently strong for this purpose. Where greater strength is required inexpensive non-corrodible alloys with improved tensile properties are available.

The physical properties. and compositions of the aluminium alloys in current use are so diverse as to preclude a discussion here on their wide variety of applications. In general, it may be said, however, that the weight of these alloys per cubic in. is about one-third that of iron or steel, and that their ultimate tensile strength ranges from 10 tons per sq. in. for sand castings up to 30 tons per sq. in. for heat-treated forgings.

Apart from constructional work, aluminium is widely employed for decorative purposes and extruded sections are specially suitable for mouldings, gutterings, etc.

B46

Intricate sections, impossible to produce by rolling or drawing, can be manufactured without difficulty by the use of the extrusion process.

Another important application of aluminium is for insulation purposes, and the AIfol principle, which has varied uses, is well known.

In this country, the biggest producer of aluminium is the British Aluminium Co., Ltd., Adelaide House, King William Street, London, E.C.4, and most of the pure aluminium used basically in the production of the many alloys that is available is supplied by this concern.

In addition to its alumina works in Scotland, where the bauxite is chemically treated to isolate the alumina, the company owns three reduction works at Lochaber, Kinlochleven mad Foyer, where the pure aluminium is produced from the alumina and cast into billets. At Warrington and Milton there are extensive works for the production of sheets and extruded sections.

In a recent publication by this concern, it is stated that the company owns over 3,000 dies for the production of extruded sections, and the many designs cover a wide field, -many of them with specific application to the commercialmotor industry.