SAFE and EASY

Page 54

Page 55

If you've noticed an error in this article please click here to report it so we can fix it.

LOADING in Milk Lorries

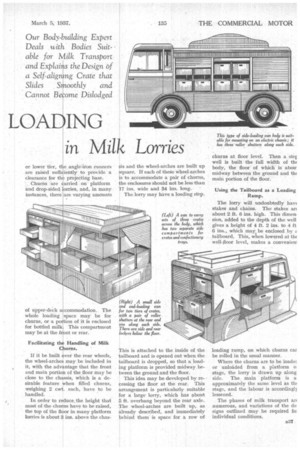

ASMALL van for carrying milk in crates often has a pair of roller shutters at the hack. When raised, the shutter reveals an upper and lower tier of angle-iron runners, which are arranged so that the crates slide in lengthwise. There are another two pairs of runners in the forward half of the loading portion, where the crates may be loaded from each side. These openings are also closed by means of roller shutters.

At the back of the van there is an tinderslung locker, also one On each side under the shutter opening, for eggs, butter, other dairy produce and groceries. The rear locker has a drop lid, which forms a step and may be utilized to facilitate access to the roof. The' roof has a double rail, .so that crates of empty bottles are safely kept in position.

With a larger chassis, the width of the body accommodates three crates and a single shutter encloses the body above the main floor level, which is above the wheel-arches. Each side of the body has two openings. The one nearer the back of the van has runners for crates, whilst the front compartment is fitted for four tiers of trays for confectionery, packets of tea and so on. A similar arrangement of lockers below the side and rear openings may be provided, as with the smaller van first described_

Another type of house-to-house delivery van is designed only for side loading. The side framework of the loading portion includes two intermediate pillars, so that the body is divided into three compartments, each accommodating two upper and n36

two tower sets of runners. If the chassis has 28-in. wheels, the floor, which clears the wheel-arches, will be about 3 ft. from the ground and the upper row of runners about 4 ft. 4 ins, from the same level, after allowing 11 ins, for the height of the crate and 5 ins, clearance between the upper and tower containers.

As the tops of the bottles are below that of the crate, it is not essential that the upper and lower • crates should each haver their own set of runners, although such an arrangement is usually preferred for quick handling and easy inspection. The crates are sometimes piled on each other, as with mineral waters. This method saves headroom and ensures

that the upper crates are within easy reach, but usually there is no device for aligning the containers, or to facilitate the sliding of one crate on top of another.

Making Provision for the Crates to

Therefore, it is suggested that the bottom crates slide between angleiron runners in the usual manner. In order that the upper ones shall slide smoothly and directly over the lower ones, the sides of the crate are about an inch higher than the ends. The bottom of each is made so that it has a projecting base. This does not extend for the full width, but sufficient space is left for a beating' on each side.

The projecting base thus forms a guide for an upper crate, because it drops between the projecting sides of the lower crate. Alignment is facilitated by tapering the' extended base at each end and rounding the corners. Moreover, the crate, presuming that all are of a standard height, slides easily over one on to the next, because the corners of the projecting sides are rounded.

To reduce friction, the bearing surface of the underside of the container may be metal-lined. In order that any crate may be placed in an upper or lower tier, the angle-iron-runners are raised sufficiently to provide a clearance for the projecting base.

Churns are carried on platform and drop-sided -lorries, and, in many instances, there are varying amounts of upper-deck accommodation. The whole loading space may be for churns, or a portion of it is enclosed for bottled milk This compartment may be at the front or rear.

Facilitating the Handling of Milk Churns.

If it be built over the rear wheels, the wheel-arches may be included in it, with the advantage that the front and main portion of the floor may be close to the chassis, which is a desirable feature when filled churns, weighing 2 cwt. each, have to be handled.

In order to reduce_the height that most of the churns have to be raised, the top of the floor in many platform lorries is about 3 ins. above the chas

sis and the wheel-arches are built up square. If each of these wheel-arches 's to accommodate a pair of churns, the enclosures should not be less than 17 ins, wide and 34 ins. Jong. ' The lorry may have a loading step.

his is attached to the inside of the aboard and is opened out when the aboard is dropped, so that a loadng platform is provided midway beween the ground and the floor.

This idea may be developed by reeasing the floor at the rear. This rrangement is particularly suitable or a large lorry, which has about ft. overhang beyond the rear axle. he wheel-arches are built up, as Iready described, and immediately • ebind them is space for a row of churns at floor level. Then a stef well is built the full width of thc body, the• floor of which is abow midway between the ground and tilt main portion of the floor.

Using the Tailboard as a Loading

The lorry will undoubtedly havc stakes and chains. The stakes an about 2 ft. 6 ins, high. This dimem sion, added to the depth of the well gives a height of 4 ft. 2 ins. to 4 ft 0 ins., which rnay..be enclosed by tailboard. This, when lowered at OA well-floor level, makes a convenieril

loading ramp, on which churns car be rolled in the usual manner.

Where the ehurns are to be loadec or unloaded from a platform cr stage, the lorry is drawn up along side. The main platform is a approximately the same level as tin stage, and the labour is according13 lessened.

The phases of milk transport an numerous, and variations of the de. signs outlined may be required to: individual conditions.