New Oil Every Mile

Page 44

If you've noticed an error in this article please click here to report it so we can fix it.

rrl-IAT oil does not wear out, but is robbed of its lubricating properties by decomposition is generally realized to-day. This fact has been proved by laboratory tests, and the salvaging of used oil by a variety of reclaiming processes is now a thoroughly practical proposition. The advantages of constantly maintaining really clean oil in the engine are obvious, however, and this is now made possible by the -use of a new device, knorrn as the Luberfiner, which is marketed in this country by Messrs. Luber-finer, Morley House, Regent Street, London, W.1.

The device is virtually a miniature oil-refining plant and the lubricant is subjected to a continual refining process, similar to that employed in the final stages of purification at a largescale refinery. Whilst the normal filter is designed to remove only the solid impurities in the oil, the Luber-finer device will remove all impurities and restore the lubricant to its original degree of efficiency ; moreover, it is claimed that it will continue to maintain the oil in a condition equal to new.

Crankcase Draining Unnecessary.

Starting with clean oil, it is claimed that the crankcase need never be drained, it being necessary only to topup as required.

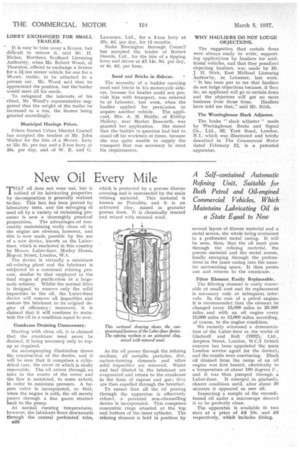

An accompanying illustration shows the construction of the device, and it will be seen that it comprises a cylindrical case, the cover of which is easily removable. The oil enters through an inlet in the centre of the cover and the flow is restricted, to some extent, in order to maintain pressure. A bypass valve is incorporated, so that, when the engine is cold, the oil merely passes through a fine gauze strainer back to the pump.•

At normal running temperatures, however, the lubricant flows downwards through the central perforated tube, B26 which is protected by a porous fibrous covering and is surrounded by the main refining material. This material is known as Percolite, and it is an activated clay, mined in granular porous form. It is chemically treated and mixed with mineral wool.

As the oil passes through the refining medium, all metallic particles, dirt, carbon-forming elements and other solid impurities are removed. Water and fuel diluted in the lubricant are evaporated and return to the crankcase in the form of vapour and gas ; they are then expelled through the breather.

To ensure that all the oil passing through the apparatus is effectively refined, a patented non-channelling device is incorporated. This comprises concentric rings situated at the top and bottom of the inner cylinder. The refining element is held in position by several layers of fibrous material and a metal screen, the whole being contained in a perforated metal casing. It will be seen, then, that the oil must pass through the refining material, the porous material and the metal screen, finally emerging through the perforations in the inner casing into time annular surrounding space. It then passes out and returns to the crankcase. .

Filter Element Easily Replaceable.

The filtering element is easily renewable at small cost and its replacement is necessary only at infrequent intervals. In the case of a petrol engine, it is recommended that the element be changed every 15,000 miles to 20,000 miles and with an oil engine every 10,000 miles to 12,000 miles, according, of course, to the engine condition.'

We recently witnessed a demonstration of the Luber-finer at the works of Gladwell • and Kell (1032), Ltd., Ampton Street, London, W.C.1 (which concern has been • appointed the main London service agent for the device), and the results were convincing. Black oil drained from the sump of an oil engine was first heated, electrically to a temperature of about 160 degrees F., and it was then pumped through a Luber-finer. It emerged in gradually clearer condition until, after about 20 minutes it appeared as new oil.

Inspecting a sample of the reconditioned oil under a microscope showed it to be perfectly clean.

The apparatus is available ifs two sizes at a price of £4 10s. and £6 respectively, which includes fitting.