A LOW-LOADING 2-TON ELECTRIC.

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

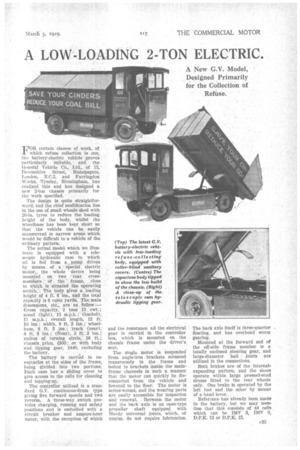

FOR certain classes of work, of which refuse collection is one, the battery-electric vehicle proves particularly suitable, and the General Vehicle Co., Ltd., of 15, Devonshire Street, Bishopsgate, London, E.C.2, and Farringdoia Works, Tyseley, Birmingham, has realized this and has designed a new 2-ton chassis primarily for the work specified.

The design is quite straightforward, and the chief modification lies in the use of small wheels shod with 26-in. tyres to reduce the loading height of the body, whilst the wheelbase has been kept short so that the vehicle can be easily manoeuvred in narrow areas which would be difficult to a vehicle of the ordinary pattern.

The actual model which we illustrate is equipped with a telescopic hydraulic ram to which oil is fed from a pump driven by means of a special electric motor,. the whole device being mounted on two rear crossmembers of the frame, close to which is situated the operating switch. The body gives a loading height of 4 ft. 6 ins., and the total capacityis 6 cubic yards. The main dimensions, ete., are as follow :— Gross capacity, 2 tons 15 cwt.; speed (light), 15 m.p.h.; (loaded), 11 m.p.h.; overall length, 12 ft. 10 ins.; width, 6 ft. 3 ins.; wheelbase, 8 ft. 3 ins.; track (rear), 4 ft. 8 ins.; (front), 5 ft. 3 ins.; radius of turning circle, 16 ft.; chassis, price, £300; or with body and tipping gear, £440, excluding the battery. The battery is carried in receptacles at the sides of the frame, being divided into two portions.

ach case has a sliding cover to give access to the cells for cleaning and topping-up.

The controller utilized is a standard G.V. continuous-drum type giving five forward speeds and two reverse. A three-way, switch provides charging, running and safety positions and is embodied with a circuit breaker and ampere-hour meter, with the exception of which

and the resistance all the electrical gear is carried in the controller box, which is mounted on the chassis frame under the driver's seat.

The single motor is suspended' from angle-iron brackets mounted transversely in the frame and bolted to brackets inside the mainframe channels in such a manner that the motor can quickly be disconnected from the vehicle and lowered to the floor. The motor is series-wound, and the wearing parts are easily accessible for inspection and renewal. Between the motor, and the hack axle is an open-type propeller shaft equipped with Hardy universal joints, which, of course, do not require lubrication.

The back axle itself is three-quarter floating, and has overhead worm gearing.

Mounted at the forward end of the off-side frame member is a totally enclosed .steering gear, and large-diameter ball joints are utilized in the connections.

Both brakes are of the internalexpanding pattern, and the shoes operate within large pressed-steel drums fitted to the rear wheels only. One brake is operated by the left foot and the other by means of a hand lever.

Reference has already been made to the battery, but we may mention that this consists of 44 cells which can be IMV 5, IMV 6, D.P.K. 13 or D.P.K. 15.