Some Sidelights on a Safety Glass.

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

The Manufacturing Methods Employed in Producing Xetal, Together with Notes on the Characteristics bf Bullet-proof Glass.

TFIE manufacturers of Xetal safety glass claim that it is 'a non-discolourable, non-inflammable, uusplinterable glass and that the process of manufacture is entirely different from that of any other similar product. In appearance very little difference can be noted between Xetal glass and ordinary glass; it can be made in any shape and any size (within reasonable limits, of course) and to any thickness, from the „finest optical glass to stout, bullet-proof glass.

As is generally imagined, Xetal glass consists of a number of sheets of ordinary glass laminated together with sheets of celluloid. This celluloid, by the way, is not an ordinary nitro-cellulose which Upon exposure to the sun, particularly in tropical zones, becomes increasingly discoloured, but is a special preparation peculiar to the Xetal Co.'s products. In passing, it might he mentioned that a Faraday House test was recently carried out to show the non-discolouring propensities of both the glass and the celluloid, for a piece of Xetal safety glass was subjected to 24 hours' exposure to the light from a large mercury-vapour lamp situated only 3 ft. away.

Half the glass was covered over, and therefore protected from therays of the lamp, but how fierce was the glare oil the exposed half will he realized when it is known that the temperature was in the neighbourhood of 77 degrees F. throughout the test. The certificate says that at the conclusion of the test no discolouration could be detected, so that it would seem that the glasSis capable of withstanding quite satisfactorily proIthiged 'exposure to a tropical sun.

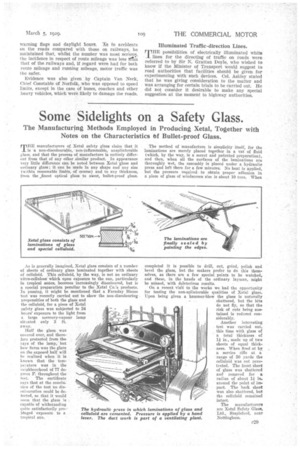

The method of manufacture is simplicity itself, for the laminations are merely placed together in a vat of fluid (which, by the way, is a secret and patented preparation), and then, when all the surfaces of the laminations are thoroughly wet, the assembly is placed tinder a hydraulic press and left there for a few minutes. No heat is applied, but the pressure required to obtain proper adhesion in a piece of glass of windscreen size is about 10 tons. When completed it is possible to drill, cut, grind, polish and bevel the glass, but the makers prefer to do this themselves, as there are a few special points to be watched, and these, in the hands of the ordinary layman, might be missed, with deleterious results.

On a recent visit to the works we had the opportunity for testing the non-splinterable qualities of Xetal glass. Upon being given a hammer-blow the glass is naturally shattered, but the bits do not fly, so that the risk of cuts being sustained is redueed considerably.

Another lute resting test was carried out, this time with glass of a total thickness of 14 in., made up of two sheets of equal thickness. When fired at by a service rifle at a range of 50 yards the celluloid was not penetrated. The front sheet of glass was shattered and removed for a radius of about 1 in. around the point of impact. The hack sheet was also shattered, but the celluloid remained intact.

The manufacturers are Xetal Safety Glass, Ltd, Stnpleford, near Nottingham.