FACTORY VISIT

Page 59

If you've noticed an error in this article please click here to report it so we can fix it.

Having missed the 1991 product launch at the home of the Ware in Luton, the departure of our long-termer coincided with the production of the four-millionth General Motors vehicle in Bedfordshire to give us an excuse for a look-around.

Although the end of passenger car production at Luton has left a large hole in the area's economy, those who only read headlines may be surprised by the extent of vehicle manufacture remaining. As well as the Frorrtera 4x4 vehicle, most of the GM Vivaria and Renault Trafics currently on Europe's roads were built there.

History lesson A quick history lesson shows that the IBC plant was set up In 1988 as a joint venture between GM Europe and [sum to build light commercials under the Bedford banner, initially building Midis which were later joined by the Suzukibased Rascal. However, at 35-40,000 units a year, production was never on a large enough scale far it to be truly profitable by current standards. But things ticked over through the nineties, aided by Frontera, until the Vauxhall/Renault joint van venture, code-named X83, came to fruition in 2001. it's not too much of an over-simplification to describe X83 as a GM-influenced Renault design with a GM-built chassis carrying a Renault driveline. There were originally around 100 Renault staff on site, but now nine remain on a project to produce a luxury seven or eight-seat passenger version and they are soon to depart, leaving just one to liaise with Franca.

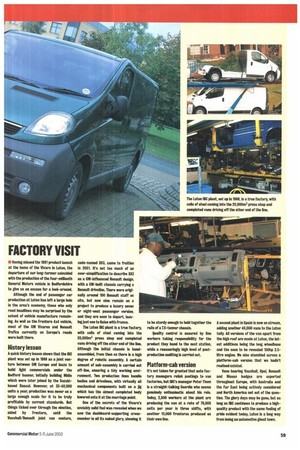

The Luton IBC plant Is a true factory, with coils of steel coming into the 20,000m3 press shop and completed vans driving off the other end of the line. Although the initial chassis is handassembled, from then on there is a high degree of robotic assembly. A certain amount of sub-assembly is carried out off-line, ensuring a tidy working environment. Two production lines handle bodies and drivelines, with virtually all mechanical components built on a jig which has the almost completed body lowered onto it at the marriage point.

One of the secrets of the Vivaro's enviably solid feel was revealed when we saw the dashboard-supporting crossmember in all its naked glory, showing it to be sturdy enough to hold together the rails of a 7.5-tanner chassis.

Quality control is assured by line workers taking responsibility for the product they hand to the next station, while a reassuringly high level of postproduction auditing is carried out.

Platform-cab version

It's not taken for granted that auto factory managers relish postings to van factories, but I80's manager Peter Thom is a straight-talking Geordie who seems genuinely enthusiastic about his role. Today, 2,500 workers at the plant are producing the van at a rate of 76,000 units per year in three shifts, with another 10,000 Fronteras produced on their own line. A second plant in Spain is now on stream, adding another 40,000 vans to the Luton tally. All versions of the van apart from the high roof are made at Luton, the latest additions being the long wheelbase arid the soon to be revealed 150hp 2,5litre engine. We also stumbled across a platform-cab version that we hadn't realised existed.

Vans bearing Vauxhall, Opel, Renault and Nissan badges are exported throughout Europe, with Australia and the Far East being actively considered and North America net out of the question. The glory days may be gone, but as long as IBC continues to produce a highquality product with the same feeling of pride evident today, Luton is a long way from being an automotive ghost town.