DOES GOODS-VEHICLE ESIGN NEED REVISION?

Page 42

Page 43

Page 44

If you've noticed an error in this article please click here to report it so we can fix it.

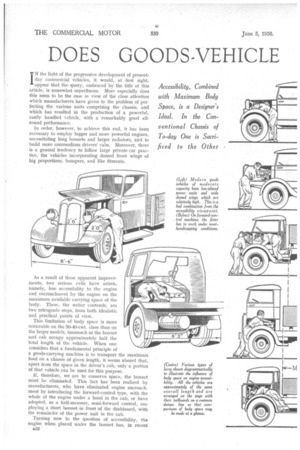

Accessibility, Combined with Maximum Body Space, is a Designer's Ideal. In the Conventional Chassis of To-day One is Sacrificed to the Other

IN the light of the progressive development of presentday commercial vehicles, it would, at first sight, appear that the query, embraced by the title of this article, is somewhat superfluous. More especially does this seem to be the case in view of the close attention which manufacturers have given to the problem of perfecting the various units comprising the chassis, and which has resulte.d in the production of a powerful, easily handled 1. chicle, with a remarkably good allround performance.

In order, however, to achieve this end, it has been neeessary to employ bigger and more powerful engines, necessitating long bonnets and larger radiators, and to build more commodious drivers' cabs. Moreover, there is a general tendency to follow large private-car practice, the 'vehicles incorporating domed front wings of big proportions, bumpers, and like fitments.

As a result of these apparent improvements, two serious evils have arisen, namely, less accessibility to the engine and encroachment by the engine on the maximum available carrying space of the body. These, the writer contends, are two retrograde steps, from both idealistic and practical points of view.

This limitation of body space is more noticeable on the 30-40-cwt. class than on tho larger models, inasmuch as the bonnet and cab occupy approximately half the total length of the vehicle. When one considers that a fundamental principle of a goods-carrying machine is to transport the maximum load on a chassis of given length, it seems absurd that, apart from the space in the driver's cab, only a portion of that vehicle can be used for this purpose.

.If, therefore, we are to conserve space, the bonnet must be eliminated. This fact has been realized by manufacturers, who have eliminated engine encroachment by introducing the forward-control type, with the whole of the engine under a hood in the cab, or have adopted, as a half-Measure, semi-forward control, employing a short bonnet in front of the dashboard, with the remainder of the power unit in the cab.

Turning now to the question of accessibility, the engine when placed under the bonnet has, in recent B32 years, lost much of its original accessibility, because frames and transmission lines have become lower, front mudguards have been widened and valances added, until it is now possible to make adjustments only by poising oneself horizontally over the wing in an extremely uncomfortable position.

Before valances were introduced, a mechanic could stand between the frame and the wing and work with ease. Regarding the semi-forward and full-forwardcontrol types, however, it cannot be said that either of these driving positions has made the lot of the repair and maintenance staff any easier, or has' improved matters for the driver who wishes to make some adjustment en route.

The writer, speaking from many years' experience, would assure manufacturers that these positions do not encourage drivers to take that important interest in their vehicles, mainly because of the discomfort and difficulty entailed.

To obtain, in substantiation of this statement, the personal views. of drivers regarding engine location, the writer has recently interrogated a considerable number of them, and, in answer to queries concerning accessibility, they have, almost without exception, stated that they much prefer the bonneted type.

One man, in speaking of his forwardcontrol vehicle, said : "Yes, we send down to the Palace of Varieties for an acrobat when we want to do adjustments." Others have stated that they " leaVe it alone until something breaks."

Now, this state of affairs is obviously highly, injurious to manufacturers and the commercial-vehicle industry in general, for not only must free replacements be more numerous and customers' complaints be increased, but also, the manufacturer tends to lose his reputation for the reliability of his products..

On the owner's part, he is eventually unable to obtain satisfactory running from his, vehicle and his repair bills may increase to an appreciable extent.

Let us, therefore, recognize the fact that the engine must be accessible, so that the driver may frequently carry out inspection or adjustments, and to enable the s33

maintenance staff to tarry out its side Of the work in comparative comfort.

The writer wishes to make it clear that his remarks are not made in any disparaging sense, for he fully realizes the difficulties that confront manufacturers in dealing with this problem, having so many times endeavoured, under manufacturing conditions, to solve or compromise in these layouts.

Accessibility Versus Body Space.

Having now touched upon the question of encroachment and accessibility, we may now review the various types of engine and cab positions in use to-day, and endeavour to analyse the pros and cons of each layout.

By referring to the accompanying illustrations it will be seen that, if accessibility be required, it must be at the sacrifice of available body space, and vice versa.

The illustration of a typical normal-control vehicle shows how the accessibility is comparatively good, but the available body space is limited. A similar type of machine is drawn with the front wheels set back. In this case the engine is easily accessible, but the body space, as before, is restricted.

The drawing of a semi-forward-control lorry demonstrates that the engine, in this case, is not so accessible. The driver or mechanic has to reach over a footboard 2 ft. wide, and is impeded by seats. Moreover, the lighting is bad. The body room, however, is increased.

In the overhead-type of vehicle, the accessibility is as

good is that of the first-named type, but the layout has the disadvantage of the driver having to climb considerably higher to his seat. Nevertheless, in this design, the. maximum available body space is provided. With forward control the maximum available body space may be utilized, but engine accessibility is on a par with that of the, semi-forward-control chassis':

From the foregoing, it will be seen that, with present design, none of the types reviewed is ideal, and, on the score of accessibility, that the engine does not lend itself to being housed in the centre of the driver's cab.

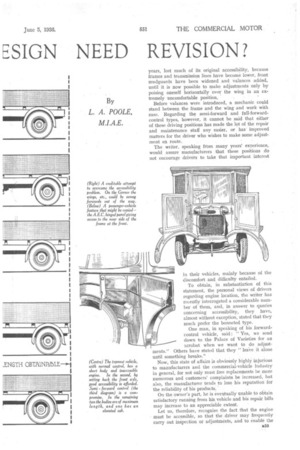

Several methods have been employed to overcome this double difficulty. One of the most ingenious, evolved by the original Garner company, was to attach the front mudguards and floorboards in such a manner that they could be swung out with the doors. By this means a fitter was enabled to get close up to his work.

A Hinged Mudguard.

Again, on an A:E.C. vehicle, exhibited at the Commercial Motor Show in November last, the front mudguard was hinged, and certainly allowed better access to the engine.

In a following article the writer proposes to show a variety of methods of overcoming these problems on lines which, whilst they may be considered unorthodox, would give the utmost accessibility combined with maximum body space, and which would, if the chassis were turned out in reasonable quantities, make for cheaper production and easier maintenance.