Good cheer at Tetley

Page 93

If you've noticed an error in this article please click here to report it so we can fix it.

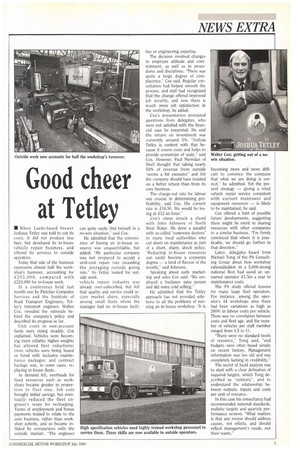

• When Leeds-based brewer Joshaua Tetley was told to cut its costs, it did not produce less beer, but developed its in-house vehicle repair business, and offered its services to outside operators.

Today that side of the business represents almost half the workshop's turnover, accounting for /2 0 5,0 0 0, compared with /224.000 for in-house work.

At a conference held last month run by Fletcher Computer Services and the Institute of Road Transport Engineers, Tetley's transport engineer, Walter Cox, revealed the rationale behind the company's policy and described its progress so far.

Unit costs in own-account fleets were rising steadily, Cox explained. Vehicles were becoming more reliable; higher weights has allowed fleet reductions; more vehicles were being leased or hired with inclusive maintenance packages; and contract haulage was, in some cases, replacing in-house fleets.

As demand fell, overheads for fixed resources such as workshops became greater in proportion to fleet size. Job cuts brought initial savings, but eventually reduced the fleet engineer's scope for recharging. Terms of employment and bonus payments tended to relate to the core business, rather than workshop activity, and so became inflated by comparison with the outside market. -The engineer

can quite easily find himself in a no-win situation," said Cox.

He admitted that the convenience of having an in-house resource was unquantifiable, but added: "My particular company was not prepared to accept a unit-cost repair rate exceeding the averaging outside going rate." So Tetley looked for outside work.

vehicle repair industry was already over-subscribed, but felt that quality and service could secure market share, especially among small fleets where the manager had no in-house facili ties or engineering expertise.

The decision involved changes in employee attitude and commitment, as well as in procedures and disciplines. "There was quite a large degree of complacency," Cox said. Regular consultation had helped smooth the process, and staff had recognised that the change offered improved job security, and now there is much more job satisfaction in the workshop, he added.

Cox's presentation prompted questions from delegates, who were not satisfied with the financial case he presented. He said the return on investment was currently around 5%. "Joshua Tetley is content with that because it covers costs and helps to provide economies of scale," said Cox. However, Paul Merridan of Shell thought that taking nearly 50% of revenue from outside -seems a bit excessive" and felt the company should have insisted on a better return than from its core business.

The charge-out rate for labour was crucial in determining profitability, said Cox. His current rate is /16.50. We would be losing at /12 an hour.

Cox's views struck a chord with John Ashmore of North West Water. He drew a parallel with so-called "corporate doctors" in many local authorities who cut down on maintenance as part of a short, sharp, shuck policy. "Reducing in-house resources can easily become a corporate dogma — a kind of flavour of the month," said Ashmore.

Speaking about early marketing and sales Cox said: "We employed a freelance sales person and did some cold selling."

He admitted that the Tetley approach has not provided solutions to all the problems of running an in-house workshop. -It is becoming more and more difficult to convince the company that what we are doing is Correct," he admitted. Yet the present strategy — giving a retail vehicle repair service consistent with current manpower and equipment resources — is likely to be maintained, he said.

Cox offered a hint of possible future developments, suggesting there might be merit in sharing resources with other companies in a similar business. "I'm firmly convinced that where it is practicable, we should go further in that direction."

Later, delegates heard from Michael Tong of the PA Consulting Group about how workshop rationalisation in a 5,000-strong national fleet had saved an unnamed operator /1.5m a year in maintenance costs.

The PA study offered lessons for many large fleet operators. For instance, among the operator's 44 workshops sites there had been variations as high as 300% in labour costs per vehicle. There was no correlation between costs and fleet age, and the number of vehicles per staff member ranged from 4.5 to 11.

"There were no standard levels of resource," Tong said, "and budgets were often based simply on recent history. Management information was too old and was completely lacking in credibility."

The secret of lucid analysis was to start with a clear defina ion of required targets, which Tong de:scribed as "outputs", and to understand the relationship between outputs, inputs and costs per unit of resource.

In this case his consultancy had recommended national standards, realistic targets and quartely performance reviews. "What matters is that any review should address causes, not effects, and should reflect management's needs, not their wants."