Sisu adds axle lift for extra traction

Page 12

If you've noticed an error in this article please click here to report it so we can fix it.

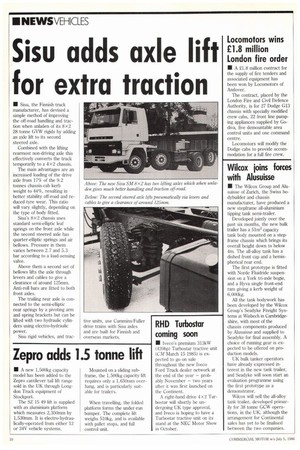

• Sisu, the Finnish truck manufacturer, has devised a simple method of improving the off-road handling and traction when unladen of its 8 x2 28 tonne G'VW rigids by adding an axle lift to its second steered axle.

Combined with the lifting rearmost non-driving axle this effectively converts the truck temporarily to a 4x2 chassis, The main advantages are an increased loading of the drive axle from 17% of the 9.2 tonnes chassis-cab kerb weight to 44%, resulting in better stability off-road and reduced tyre wear. This ratio will vary slightly, depending on the type of body fitted.

Sisu's 8x2 chassis uses standard semi-elliptic leaf springs on the front axle while the second steered axle has quarter-elliptic springs and air bellows. Pressure in them varies between 2.7 and 5.3 bar according to a load-sensing valve.

Above them a second set of bellows lifts the axle through levers and cables to give a clearance of around 125mm. Anti-roll bars are fitted to both front axles.

The trailing rear axle is connected to the semi-elliptic rear springs by a pivoting arm and spring brackets but can be lifted with two hydraulic cylinders using electro-hydraulic power.

Sisu rigid vehicles, and trac tive units, use Cummins/Fuller drive trains with Sisu axles and are built for Finnish and overseas markets.