Whale Tankers are becoming big fish

Page 96

Page 97

Page 98

If you've noticed an error in this article please click here to report it so we can fix it.

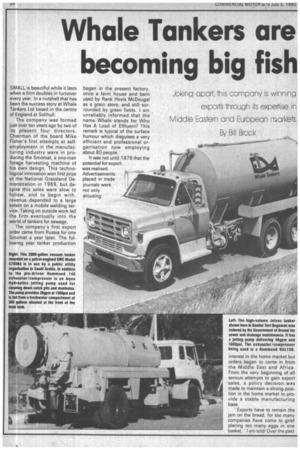

Joking apart, nis company is winning exports through its expertise in Middle Eastern and European mar,ets. By Bill Brock

SMALL is beautiful while it lasts when a firm doubles in turnover every year. In a nutshell that has been the success story at Whale Tankers Ltd based in the centre of England at Solihull.

The company was formed just over ten years ago by two of its present four directors. Chairman of the board Mike Fisher's first attempts at selfemployment in the manufacturing industry were in producing the Smornat, a one-man forage harvesting machine of his own design. This technological innovation won first prize at the National Grassland Demonstration in 1969, but despite this sales were slow to follow, and to begin with. revenue depended to a large extent on a mobile welding service. Taking on outside work led the firm eventually into the world of tankers for sewage.

The company's first export order came from Russia for one Smomat a year later. The following year tanker production began in the present factory, once a farm house and barn used by Rank Hovis McDougal as a grain store, and still surrounded by green fields. I am unreliably informed that the name Whale stands for Who Has A Load of Effluent? This remark is typical of the surface humour which disguises a very efficient and professional organisation now employing about 80 people.

It was not until 1976 that the potential for export was realised. Advertisements placed in trade journals were not only arousing interest in the home market but orders began to come in from the Middle East and Africa. From the very beginning of all serious attempts to gain export sales, a policy decision was made to maintain a strong position in the home market to provide a stable manufacturing base.

"Exports have to remain the jam on the bread, for too many companies have come to grief placing too many eggs in one basket,' I am told! Over the past few years, with expansion in both markets, exports have been responsible for about one third of the company's turnover.

Large orders can produce complications for a small firm. If production is allowed to become monopolised by a single order, other customers may be kept waiting and go elsewhere to meet delivery datelines. While all orders may seem attractive, they are worthwhile only at the right price. At Whale this means each must be made to fit production schedules without dominating the whole factory. In normal circumstances this can be simply achieved by spreading delivery over a period of time.

Tony Balwin, export sales manager, explained that the formula of success abroad is to provide the customer with a personal service, which gives him a product to suit his needs, delivered on time with a back-up service he can rely on. All orders are dealt with similarly.

On receipt of a sales inquiry from anywhere in the world a quotation is sent by telex on the same day. All shipping documentation, including insurance and if need be, finance, irrespective of the size of the order, can be handled by Whale. The vehicle chassis on which the tank will be mounted can be obtained direct from the manufacturers in many cases. Each foreign order is commissioned on site so that the customer and driver become acquainted with the equipment and vehicle and any small problems can be sorted out on the spot before going into service.

Whale's range of tankers has been increased enormously since its early days and now includes effluent tankers, cesspool emptiers, water tankers, gully emptiers and street washers. The Jetvac was the first Continental-type combined sewer-jetter /cesspool emptier to be produced by a British manufacturer.

The Combination, another model, capable of sewer-jetting and gully or cesspool emptying, can also do the job of two vehicles. Rotovac, another registered trade name, is a vacuum/pressure pump tanker used on land spreading. Special vehicles have also been developed to deal with crude oil and bitumen residues in storage tanks.

In some of the developing countries the more simple de

signs, such as for water tankers, are being superseded by locally built vehicles.

The export market is strongest for the more sophisticated machinery which nevertheless must be robust and simple to operate. Account needs to be taken of local operational difficulties. Sewers are often primitive and surface drains fill up with sand for most of the year only to become blocked when it finally does rain.

The specification of vehicle chassis will often depend on which manfacturer is predominant in the operational area. It is no good providing a vehicle which has no local dealer back-up. All too often, Tony tells me, this means using an imported chassis as British manufacturers do not have the local representation necessary.

Reliability and service are the key to future sales. No distinction is made by many operators between the chassis and its tank equipment. Instruction for the man who works the vehicle is an area which has shown positive results and the Whale insignia attached to all export tanks is held in high esteem.

Europe is a much harder market in which to compete. All too often the stigma, which is attached to the British industrial scene in • general, affects good and bad manufacturers equally. To gain an order here the customer has first to be convinced that delivery dates can be met and the standard of engineering will be up to the required level. One such customer placed an order but stipulated that it should not be painted before he had flown over from Holland with his chief engineer to inspect the welds, as he knew that "the British only make cheap crap". On arrival after the subsequent inspection the tank was pronounced to be faultless.

Soon after delivery, however, this customer was on the phone to complain that he had asked for the vehicle to have a balanced propshaft but no balance weights had been fitted. Mike Fisher took great delight in explaining that the British propshaft is a precision piece of equipment and does not need any weights. Even though Whale has since put up its prices so that its equipment could not be said to be "cheap," this customer has returned for more vehicles. He retorted: "They're British crap, but good crap," proving that the Dutch have a sense of humour, too.

Influenced by the British reputation, a Norwegian customer reluctantly placed his order in Italy to ensure delivery on time. After 12 months he came back with the remains of the Italian tank and asked for it to be removed and replaced with one of the original specifications.

For Whale, being top of the bottom business is no idle boast, for the company, after only just a decade in the business, dominates the UK market. Company attitude to safety is a responsible one. Every tank is tested hydraulically and mechanically to twice its working pressure for a duration of one minute.

Some are tested before and after painting and all by qualified staff. All Whale-built components have a lifetime guarantee invalidated only by normal wear and tear. Bought-in parts are guaranteed for 12 months, Since 1973 Mike Fisher has spent many hours discussing safety of operation and maintenance of vacuum/ pressure tanks used in the waste disposal transport industry, first with the Home Office and more recently with the Health and Safety Executive.

Existing and stringent regulations in existence covering static pressure vessels are unsuitable, he says. Mike Fisher believes that regulations are more likely to hinder the improvement of safety than to aid it.

"What seems to be beyond the grasp of most of those concerned," he said, "despite the small number of accidents known and the fact that they do not indicate constructional defects, is that vacuum tankers are inherently remarkably safe.

"The only scope for improvement lies in maintenance and operational procedures. To that end Whale has produced its own 11-part code of practice covering such items as insurance, use, maintenance, marking, testing, working life and design."

An abbreviated version of five safety rules, covered fully in the safety maintenance and safety operation schedule, under Section 4 of the Code, is provided free on windscreen sunstrips, serving as a constant reminder to the driver not to touch clamps while pressure remains in the tank, and to tighten and loosen clamps only when there is vacuum in the tank.

Drivers must make sure all clamps are sealed on the door, and check weekly that all clamps and pressure relief valves are in good order. Fitters must always gas free the tank before welding.

Situated close to the NEC, at Birmingham, Whale has the contract to service the exhibition site's drains, and this makes things convenient for demonstrations at show time.

Delivery is described as being flexible, but orders have been gained by producing a completed vehicle in only six weeks which included obtaining a chassis from a foreign manufacturer.

Dock strikes can be a nightmare. Delivery dates, imposed by the letter of credit, normally have a 14-day negotiation period — but some do not.

Maintenance manuals in Arabic, German. French and English are a sales aid, but being able to produce vehicles from six tons to 38 tons gross in three basic categories, each with 50 options, gives the form the versatility needed in order to compete.