Delivery Van Built for Hard Work

Page 48

Page 49

Page 50

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

By John F. Moon, A.M.1.R.T.E.

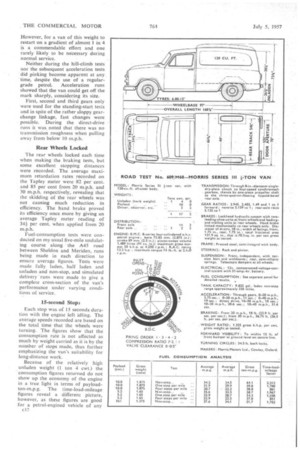

LONG operational life can safely be forecast for the latest Morris +-ton van; even the out ward appearance suggests rock-like reliability and detailed inspection of the design bears out this impression. Strength has not been accomplished without some understandable weight increase, with the result that the van weighs more than other +-ton vehicles built by the British Motor Corporation. The slightly heavier fuel bills likely to arise will be more than compensated by the longevity of the design and the ability of the van to stand up to rough use.

Powered by a B.M.C. B-series four-cylindered o.h.v. 50 b.h.p. petrol engine, the van is deceptively lively on the road, as borne out by the acceleration times recorded on test. The engine characteristics endowed by the S.U. carburetter demand full use of the accelerator pedal if the best performance is to be obtained, hut this does not result in excessive fuel consumption.

A distance of 478 miles was covered during the test and the overall consumption rate was 26.5 m.p.g., including all the test work and several fast long-distance runs carrying a full load.

Because of the roomy and comfortable cab, the Morris van is suitct 0 able for long-distance runs, although primarily a local delivery vehicle, and this attribute makes it attractive for general operation overseas. Moreover, the suspension, although a little soft by normal British standards, should cope ably with dirt roads and other rough surfaces in a way normally associated only with American vehicles.

The van has a 120-cu.-ft. all-steel body which is not completely integral with the chassis. The pressed-steel

chassis frame is integral with the cab and front-end assembly, but the. body is rubber-mounted on the frame and bolted to the back of the cab. panels. The interior finish of the cab is first class, and includes such safety features as a dished steering wheel and foamrubber crash pads along the width of the facia panel.

Twin driving mirrors are standard equipment.

. At the slight sacrifice of a smooth exterior roof line an interior body height of almost 4-ft. has been achieved. An interior lamp is provided just inside the rear doors, and protection laths an be used as lashing rails. The central floor section consists of three easily removable metal panels incorporating wooden wearing strips. The flat-topped wheelarches are useful.

Mechanically the van is similar to the Morris Oxford private car, which forms the basis also for its styling. The 1.489-litre engine has leadindium crankshaft bearings, and the standard compression ratio of 7.2 to 1 allows the use of regular-grade fuels without pinking. An S.U. electric petrol pump is mounted directly on the petrol tank to reduce the risk of vapour locks forming at high altitudes.

A four-speed synchromesh gearbox is mounted i as a unit with the engine. It has a steering-column gear-change linkage which, it must be confessed, was by no means foolproof on the vehicle tested. At one stage during the test this linkage seized up completely, apparently because a loose piece of swarf fouled one of the bearings.

Inclined Rear Dampers The rear axle is a three-quarterfloating unit, with hypoid-bevel finaldrive gearing. Semi-elliptic springs, mounted on rubber to reduce noise transference, form the rear suspension, in conjunction with inclined telescopic dampers. This arrangement was found on test to have good antiroll properties. The front suspension consists of longitudinal torsion bars, with pressed-steel wishbones and telescopic dampers, inclined as at the rear.

Direct-acting rack-and-pinion steering is employed, and over, all but very smooth road surfaces tends to cause slight reaction to be felt at the steering wheel. Generally, however, the steering is good and combines with the suspension to allow fast cornering with confidence.

It had been arranged that I should borrow a van. from Colmore Depot, Ltd., Birmingham distributors for Morris cars and commercial vehicles. The van was finished in the Coln-tore Depot colours, which showed off its lines to advantage. A test load

weighing 10 cwt. had been provided.

The test vehicle had a benchtype seat, this being standard on export vans but optional equipment for the home market, costing an additional £10. Nonstandard mirrors were mounted some way forward along the front wings, giving better rearward visibility than is possible with the mirrors in the standard position close to the windscreen. The van had covered 1,160 miles before my .test, so it was well run-in.

Hill-climbing and brake-fade tests were conducted first, the half-mile gradient of Succombs Hill being chosen. This _hill, one of the steepest in the Home Counties, has an average gradient of I in 9 and sections of up to 1 in 41-.

The climb was made in an ambient temperature of 50°F. and at the start of the test the coolant was at a temperature of 169°F, A fast climb was then made in 1 minute 23 seconds, which caused a temperature rise of 17°F. During the ascent bottom . gear was used twice for a total time of 25 seconds.

The hill was descended in neutral at a speed varying between 15 M.p.h. and 20 m.p.h., using the foot brake to restrict the speed. The run took 1 minute 10 seconds and an emer

gency stop from 20 m.p.h. at tne bottom of the hill produced-a Tapley meter reading of 79 per cent., indicating that little fade had occurred when comparing this figure with the 82 per cent. recorded during the normal brake tests...

On the 1 in 5 section a successful bottom-gear restart was made while carrying a passenger, but on the 1 in 4+ section it was only just possible to restart, even after my passenger had got out. On both slopes the hand brake held the van with ease, the pull-up lever allowing plenty of pressure to be applied to the rear brakes. This lever is to the right of the driving seat, where it is easy to reach and does not obtrude into the passenger space.

From the van's performance on this hill it is obvious that the engine was working at the top limit of its power. This was verified by the fact that the water temperature had risen to 200°F. during the stop-start tests. However, for a van of this weight to restart on a gradient of almost I in 4 is a commendable effort and one rarely likely to be necessary during normal service.

Neither during the hill-climb tests nor the subsequent acceleration tests did pinking become apparent at any time, despite the use of a regulargrade petrol. Acceleration runs showed that the van could get off the mark sharply, considering its size.

First, second and third gears only were used for the standing-start tests and in spite of the rather sloppy gearchange linkage, fast changes were possible. During the direct-drive runs it was noted that there was no transmission roughness when pulling away from below 10 m.p.h.

Rear Wheels Locked The rear wheels locked each time when making the braking tests, but some excellent stopping distances were recorded. The average maximum retardation rates recorded on the Tapley meter were 82 per cent. and 85 per cent from 20 m.p.h. and .A0 m.p.h. respectively, revealing that the skidding of the rear wheels was not causing much reduction in efficiency. The hand brake proved its efficiency once more by giving an average Tapley meter reading of 34+ per cent. when applied from 20 m.p.h.

Fuel-consumption tests were conducted on my usual live-mile undulating course along the A45 road between Sheldon and Meriden, runs being made in each direction to ensure average figures. Tests were made fully laden, half laden and unladen and non-stop, and simulated delivery 'runs were made to give a complete cross-section of the van's performance under varying conditions of service.

15-second Stop3 Each stop was of 15 seconds duration with the engine left idling. The average speeds recorded are based on the total time that the wheels were turning. The figures show that the consumption rate is not affected as much by weight carried as it is by the number of stops made, thus further emphasizing the van's suitability for long-distance work.

Because of the relatively high unladen weight (1 ton 4 cwt.) the consumption figures returned do not show up the economy of the engine in a true light in terms of payloadton-m.p.g. The time-load-mileage figures reveal a different picture, however, as these figures are good for a petrol-engined vehicle of any c12 sort, as are the gross-ton-m.p.g. values.

There is ample room on the benchtype seat for two passengers without cramping the driver, and the steering column is raked slightly to the off side to make the driver tend to sit well over to that side. Because of this column angle the pedal grouping is a little close, but the pedals are large and I quickly became accustomed to their layout.

Few Body Rattles At normal road speeds engine noise did not become unduly pronounced, but in the indirect ratios the gearbox was surprisingly noisy. Few body rattles became apparent during the test, but on rough road surfaces a certain amount of drumming was noticed, Only slight oversteering was noticed when cornering quickly with a full load.

An engine characteristic that will be found tiresome by delivery-van drivers is the time taken for the unit to warm up fully and the speed with which the coolant temperature drops when the van is stationary. In an ambient temperature of about 50°F. the choke has to be used for at least seven minutes when starting from cold before the engine will pull strongly.

A comprehensive set of instruments is provided, including a trip mileometer, and the control knobs are much closer to the driver than they were on the previous Morris Oxford car which went out of production last year. Self-parking windscreen wipers are fitted, but these leave a large section of the centre of the windscreen unwiped.

A sun visor is a standard fitting. The cab door window winders are slow-acting, taking 2-1 turns of the handle for full travel.

For my maintenance tasks I used the tools provided in the tool kit, which is reasonably comprehensive except for the inclusion of only one open-ended spanner. Good access to the engine is given with the bonnet raised, and it takes 22 seconds to lift the bonnet and apply the prop. This done, the water level can be checked in 6 seconds and the engine oil level verified in 22 seconds.

The 12-volt battery is located above the off-side front wheel, where it is clear of the engine but easy to reach, I was able to check the electrolyte levels in 35 seconds, following which I removed and replaced one of the sparking plugs in a total time of 55 seconds, access to the plugs being equal. The contactbreaker gap was checked in 11 Minutes without too much trouble, a starting handle being provided.

Air Cleaner Removed To inspect the oil level in the -air cleaner it is easiest to remove the cleaner from the engine: this entails slackening one hose clip and a spring clip on the breather pipe, the filter cover then being easy to remove. This level took 23( minutes to check, including removal and replacement time.

The gearbox dipstick is reached by pulling up the rubber cab-floor mat and removing a rubber bung in the floor to the right of the gearbox cowl. This was all easy, and I checked the level in 39 seconds. The rear-axle oil level took 11minutes to verify, it being necessary to crawl beneath the van to gain access to the combined filler and level plug in the rear of the axle case. A separate compartment below the body houses the spare wheel and a hinged flap secured by two budget locks gives easy access to this. It was a simple matter to remove the wheel in 30 seconds, whilst replacement took only 40 seconds. An advantage of this method of stowage is that there is no need to disturb the load to remove the wheel, not that this should often be necessary as tubeless tyres are fitted.

Brake Adjustment Using the screw jack provided in the tool kit I jacked up and removed the off-side rear wheel in 4 minutes, replacement taking a further 21i minutes. To adjust any of the brakes it is necessary, unfortunately, to remove each wheel, so allowing 30 seconds to adjust each brake with the wheel off it takes 7 minutes to adjust one—nearly half an hour for all four.

Unpainted, the van has a basic price of £528—£12 more than the previous model—whilst the purchase tax has been reduced by 19s. 8d., being now £85 9s. 9d. Painting in standard works colours costs an extra £5 10s. The standard van for the home market is supplied with a single bucket-type driving seat, but a passenger seat can be obtained for £7 15s. if fitted at the factory.

A pick-up version of the van is also made. It has an identical mechanical specification, so its road performance will be largely similar to that of the van, allowing for a slightly lower unladen weight. This costs £11 10s. less than the van, and can be supplied with a tilt for £20 15s. The 1-tonner is available as chassis and cab only, with or without the cab back panel, for specialized bodywork.