A New Entrant to the Tipping-gear Field

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

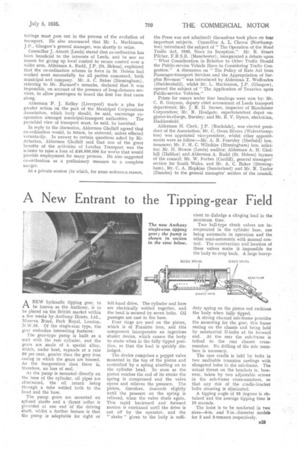

ANEW hydraulic tipping gear, to be known. as the Anthony, is to be placed on the British market within a few weeks by Anthony Hoists, Ltd., Minerva Road, Park Royal, London, N.W.10. Of the single-ram type, the gear embodies interesting features.

The gear-type pump is built as a unit with the ram cylinder, and the gears are made of a special alloy, which, under heat, expands at a rate 50 per cent. greater than the grey iron casing in which the gears are housed. As the temperature rises there is, therefore, no loss of seal. '

As the pump is mounted directly on the base of the cylinder, oil pipes are eliminated, the oil return being through a tube welded both to the bead and the base.

The pump gears are mounted on splined shafts and a thrust collar is provided at one end -of the driving shaft, whilst a further feature is that the pump is adaptable for right or

left-hand drive. The cylinder and base are electrically welded together, and the head is secured by seven bolts. Oil passages are cast in the base.

Four rings are used on the piston, which is of Frankite iron, and this component incorporates an ingenious shaker device, which causes the body to shake when in the fully tipped position, so that the load is quickly dislodged.

The device comprises a poppet valve mounted in the top of the piston and controlled by a spring abutting on to the cylinder head. So soon as the piston reaches the end of its stroke the spring is compressed and the valve opens and relieves the pressure. The piston, therefore, descends slightly until the pressure on the spring is relieved, when the valve shuts again. This rapid backward and forward motion is continued until the drive is Cut off by the operator, and the " shake " given to the body is suffi duty spring on the piston rod cushions the body when fully tipped.

A strong channel sub-frame provides the mounting for the gear, this frame resting on the chassis and being held by substantial U-bolts at its forward end. At the rear the sub-frame is bolted to the rear chassis crossmember. No drilling of the side members is necessary.

The ram cradle is held by bolts in two malleable trunnion castings with elongated holes in the sub-frame. The actual thrust on the brackets is, however, taken by two adjustable screws in the sub-frame cross-members, so that any risk of the cradle-bracket bolts shearing is eliminated.

A tipping angle of 55 degrees is obtained and the average tipping time is 10 seconds.

The hoist is to be marketed in two sizes-6-in. and 7-in.-diameter models for 2 and 3-tanners respectively.