)cl. for Performance nd Construction

Page 43

Page 42

Page 44

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

By L. J.

N,

M.1

APART from its payload rating and title, the Thornycroft Sturdy Star bears little relationship . to its predecessor, a model which has been in continuous production for over 14 years. The square frontal styling of the former Sturdy has been exchanged for a pressed-steel cab having well-blended curves, giving an attractive and Modern appearance. A. new direct. injection oil engine replaces the earlier precombustionchamber unit and the transmission now includes a five speed gearbox and a hypoid-d riven axle. In addition. the Star model has a robust frame and front axle, which

have been " borrowed " from the Trident class. • An extended road trial emphasized the spaciousness of the new cab and showed that the addition of 49 lb. to the weight is well justified. The engine noise is far less than that of the average small oiler, and the general performance is second to none in its class.

The Sturdy Star has keen competition from other makes in its field, and in designing this model the Thornycroft engineers have set out to enhance the reputation for performance, as well as quality.

Cab Refinements

The cab would satisfy the whims of the most critical driver, who benefits by an adjustable seat, with real hide covering, a telescopic steering column, well-placed controls, an easy-change gearbox, quick-drop windows, and almost as much space as on a semi-forward-control chassis. There was no trace of panel drumming or creaking When the chassis was on the road or under deflection, and visibility, with front screens each measuring 2 ft. 6. ins. by 2 ft., was exceptional.

The Thornycroft TR6 direct-injection engine used in

the Star model, has a monobloc cast-iron crankcase and cylinder block, and a head which covers all six bores. This unit has the same stroke as the former precombustion chamber engine, but the bore is increased to 35 ins, and the maximum torque raised by 6 lb-ft.. to . 174 lb.-ft. at 1,300.r.p.m. The crankshaft is supported by seven pre-finished Shell bearings, with white-metal upper halves and copper-lead lower halves. The bigend-bearing shells are lined with copper-lead at the top and white metal at the bottom. • In the lubrication system, oil returning to the base is passed through a primary box screen and an external by-pass filter. Apart from the fan and Water pump, all other auxiliaries arc driven by chain and sprockets, the brake exhauster being fitted below the fuel-injeetion pump and driven in tandem with the dynamo. Air for

ati combustion is drawn through an oil-bath cleaner, located in the cab in front of the steering column, with an intake below the floor plates to eliminate induction roar.

The power unit is relatively shallow, and being fairly low slung in the chassis, occupies only a small space in the cab. There is ample space around the unit for air to flow, so that comparatively little heat is passed to the surrounding bonnet. I noticed this particularly during the test, which was made on a cold day, with an outside temperature of 44 degrees F. Even during hill-climbing, the bonnet temperature barely approached a tepid heat, arid the maximum temperature recorded in the cab was 53 degrees F.

The bonnet is a fixed structure with a removable top giving access to the valves for adjustment, injector maintenance or head retnoval, and a detachable panel through which the fuel-injection pump and filter may be reached. Fuel is supplied to the pump through an Autovac on the near side of the cab.

Engine, clutch and gearbox arc mounted as a unit in the frame, supported on a pair of Silentbloc assemblies at the front of the timing case and another pair at the gearbox end. Torque-reaction snubbers are arranged on each side of the flywheel housing. This suspension system is sufficiently resilient to absorb engine vibration, but the limit of movement. is controlled to ensure that no unpleasant whip occurs at the end of the long gear lever.

The overdrive gearbox has dog-clutch engagement for fifth and fourth ratios, and the lowest three ratios are operated through conventional sliding spur eears. Taken

in conjunction with the 6.166-to-1 final-drive ratio, the overall ratio in overdrive is 4.93 to 1. The gearbox has a cast-iron case, and Lh& selector lever is carried on a turret secured to the top of the box.

A divided propeller shaft, with a Layrub coupling at the front and a flexibly Mounted bearing at the centre. takes the drive to the hypoid gear of the rear axle. A pressed-steel case is used -and the hypoid pinion and crown wheel are supported on roller bearings, the pinion being straddle-mounted..

The chassis frame, together with the front axle, are traditionally Thornycroft in robustness. Formerly the Sturdy was equipped with a normal hydraulic braking system, but to this has been added a Clayton Dewandre vacuum servo— which, in the Star model, affords high efficiency at the wheels for little manual effort. The servo and hydraulic master cylinder are combined as a unit and attached to the side of the frame.

A point of interest in the latest Sturdy is the method of securing the cab to the chassis. To absorb chassis deflection it is carried on four flexible mountings and a pinand-socket electrical connector simplifies the removal of the cab for major engine repairs.

The Sturdy Star is available in leftor right-hand-drive normalcontrol or right-hand forwardcontrol form. My test model was a forward-control chassis, with a Thonveroft built light alloy platform body. This body comprises two longitudinals of open box section, secured to the frame by U-bolts. Eight light-alloy cross-members of similar section are bolted to the longitudinals, and the main floor members, 9 ins. wide, are secured to the top. These are fixed in position by clamp strips of siaitable section to receive a T-headed bolt, thus providing a platform body which is devoid of crevices. A fine powder load, such as cement, is thereby prevented from seeping through the floor on to the transmission. The front head board rises I ft 4 ins.

above platform level, and the side rails provide a 2-in. abutment With this body fitted, and in licensing condition, the vehicle has 63 lb. to spare under the 3-ton weight limit and is therefore within the 30 m.p.h. class. The It yload, together with chocks to prevent movement of the load, and tools, spare wheel and fuel, brought the running weight up to 81tons, which is the maximum advocated load for 34 by 7-in. tyre equipment.

1 admired the appearance of the Sturdy Star when it was shown at Earls Court, and my enthusiasm for this model increased during its test.

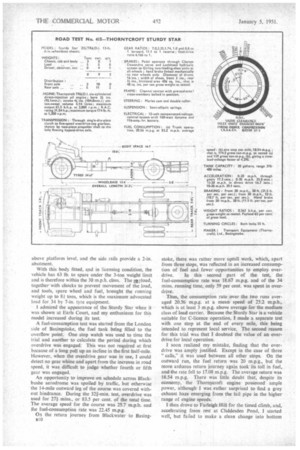

A fuel-consumption test was started from the London t:ide of Basingstoke, the fuel tank being filled to the overflow point. One stop watch was used to time the trial and another to calculate the period during which overdrive was engaged: This was not required at first because of a long pull up an incline in the first half-mile. However, when the overdrive gear was in use, I could detect no gear whine and apart from the increase in road speed, it was difficult to judge whether fourth or fifth gear was engaged.

An opportunity to improve on schedule across Blackbushe aerodrome was spoiled by traffic, but otherwise the 14-mile outward leg of the course was covered without hindrance. During the 32i-min. test, overdrive was used for 27f mins., or 83.5 per cent. of the total time. The average speed for the course was 25.7 m.p.h. and the fuel-consumption rate was 22.45 m.p.g. On the return journey from Blackwater to Basing810 stoke, there was rather more uphill work, which, apart from three stops, was reflected in an increased consumption of fuel and fewer opportunities to employ over drive. In this second part of the test, the fuel-consumption rate was 18.67 m.p.g. and of the 34 mins. running time, only 59 per cent. was spent in overdrive.

Thus, the consumption rate over the two runs averaged 20.56 m.p.g. at a mean speed of 25.2 m.p.h., which is at least 3 m.p.g. above average for the medium class of load carrier. Because the Sturdy Star is a vehicle suitable for C-licence operation, I made a separate test with one stop at the end of every mile, this being intended to represent local service. The second reason for this trial was that I doubted the value of an overdrive for local operation.

I soon realized my mistake, finding that the overdrive was amply justified. Except in the case of three "calls," it was used between all other stops. On the outward run, the fuel return was 20 m.p.g., but the more arduous return journey again took its toll in fuel, and the rate fell to 17.08 m.p.g. The average return was 18.54 m.p.g. There was little doubt that, despite its economy, the Thornycroft engine possessed ample power, although I was rather surprised to find a grey exhaust haze emerging from the tail pipe in the higher range of engine speeds.

I then drove to Farleigh Hill for the timed climb, and, accelerating from rest at Cliddesden Pond, I started well, but failed to make a clean change into bottom gear as the gradient increased. The works tester also "muffed" the gear change at the first attempt, but subsequently all the valuable seconds were preserved, and the hill was climbed in 5 mins_ 34 secs., corresponding to an average speed of 15.05 m.p.h. The observed length of Earleigh Hill is 1.4 mites, and the average gradient is 1 in 27, the maximum incline being 1 in 8.4. Although low gear was required for the steep section. the Sturdy Star has sufficient reserve power to climb a I-in-41 gradient with full load.

From Farleigh [drove to the Andover side of Basingstoke in preparation for the braking test. Unfortunately, the road surface was sodden and the wheels locked throughout the trials. To ensure complete accuracy in measuring brake stopping distances, a special marker was used. This comprised an air pistol, which, connected to a switch on the brake pedal to actuate a solenoid attached to the trigger, fired a paint-covered slug on the road to mark the point where the pedal was applied.

New Standard of Accuracy The time delay of the solenoid (0.036 sec.) is compensated for in the results by adding 1.1 ft. to the measured slopping distance from 20 m.p.h. and 1.6 ft. from 30 m.p.h. This method of marking and measuring stopping distance is more accurate than is obtained with the normal instruments available, or by the visual means formerly employed iii" The Commercial Motor " tests. The vehicle could be brought to rest from 20 m.p.h. in 20 ft.. and from 30 m.p.h. in 52 ft.

Next I tested for brake .fade by driving against the braking system. The first check, at the end of three miles. produced a stopping distance or 50 ft. from 20 m.p.h.. with a full application of the pedal. There were signs of heating from the drums, and the paint on them had charred.

At the end of the fourth and fifth miles there were no further signs of fade, so I continued the treatment for seven miles. but still the stopping distance remained between 49 ft. and 50 ft. Deadlock having been reached, I gave up the attempt to make the brakes fade completely. The rate of recuperation was as remarkable as the lack of fade and within the first mile the measured stopping distance from 20 m.p.h. fell to 28 ft.

I could find nothing unusual :in the system to account for . so slight:a tendency to fade and for -the rapid recovery. It could be that the heavy drums, coupled with ample air space at the periphery., assists heat dispersal, but, on the other band, the wedge angle of the Girling units, as fitted. to the Thornycroft, should tend towards early fade. Wedges of 101-degree angle are used at the rear and 13 degrees at the front.

Maximum of 42 m.p.h.

The acceleration trials were made in all gears except overdrive, and with gear changes at 7, 11 and 20 m.p.h. Compared with other vehicles of the same class, the Sturdy Star has a normal acceleration rate, the time taken to reach 30 m.p.h. from rest being 35.8 secs., and the direct-drive acceleration from 10-30 m.p.h. occupying 39.1 secs. At the end of these trials, I engaged. the overdrive at 30 m.p.h., and tried the vehicle for maximum speed, which, on level grotind,'w.as 42 m.p.h.

Although a blind was fitted across the .lower half of the radiator, the top-tank temperature refused to rise above 118 degrees F., even when hill..climbing or during the short performance trials. The temperature during normal main-road work was 96-104 degrees F. Because of obstacles which prevented the entry of a stick thermometer. I was unable to check the lubricant temperature of the gearbox or engine. The highest axle temperature recorded was 102 degrees F.

A 3.865-litre petrol engine developing 68 b.h.p. 2.600 r.p.m. and 163 lb.-ft. torque at 1,400 r.p.rn. is available in this chassis and is fitted in conjunction with a four-speed direct-drive-top gearbox. Other variations in the Sturdy Star range include tippers and tractors of different wbeetbases, and a lower-ratio axle for operation in very hilly areas or under exceptional service conditions.