The Bes Ways of

Page 46

Page 47

Page 48

If you've noticed an error in this article please click here to report it so we can fix it.

CARRYINC LUGGAGE

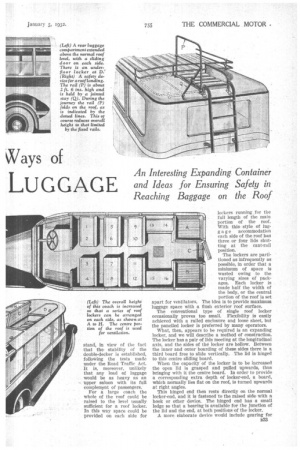

WHEN it is decided to carry luggage inside the bus or coach, at the rear, the -chief problem to consider is to what extent such an arrangement will affect the seating capacity. In one instance. the body is long enough for seven rows of seats all facing forwards.

From the bulkhead to the back of the first row of seats measures 3 .ft., and the other rows are 2 ft. 6 ins. apart. If each measurement be decreased 2 ins., then 1 ft. 2 ins, is available for a rear compartment. without affecting the number of seats originally planned, whilst a reasonable seating comfort is .maintained.

With a small or medium-sized vehicle, which has lengthwise seats over the wheel-arches, the size of the rear compartment is determined by the number of passengers that each wheel-arch seat is to accommodate.

Another factor is whether the luggage space is to extend right across the body, with the emergency exit on the off side, or whether the central gangway is to be continued and divide the luggage space into two separate compartments, with the exit at the back.

In other instances the luggage compartment takes tip the same amount of space as does a row of crosswise seats, that is, from 2 ft. 3 ins. to 2 ft. 6 ins. If the luggage space represents a definite number of seats, the body may be designed so that these seats are available when no luggage is carried.

Any rear partition is made removable, and the seats are of the folding or easily removable pattern. This arrangement gives scope for a wide variation of the proportion of passenger to luggage-carrying capacity. The vehicle has, however, to be licensed according to its maximum seating capacity.

In order" to make the utmost use of.the back of the vehicle, the radius of the rear rounded corners should B32

be small, whilst the space can be increased by building upwards beyond the normal roof level. Such an extension is shap&l to resemble a roof locker.

Carrying luggage on the roof is now a well-established practice. An opening roof restricts the size of the space which may be devoted to baggage, but even when the roof is a fixture it is not often that one finds the whole length used as a loading area.

This is not easy to under stand, in view of the fact that the stability of the double-decker is established, following the tests made under the Road Traffic Act. It is, moreover, unlikely that any load of luggage would be as heavy as an 'upper saloon with its full complement of passengers.

For a large coach the whole of the roof could be raised to the level usually sufficient for a roof locker. In this way space could be provided on each side for

lockers running for the full length of the main portionof the roof. With this style of luggage accommodation

each side of the roof has three or four lids shutting at the cant-rail position.

The lockers are partitioned as infrequently as possible, in order that a minimum of space is wasted owing to the varying sizes of packages. Each locker is made half the width of the body, or the central portion of the roof is set apart for ventilators. The idea is to provide maximum luggage space with a flush exterior roof surface.

The conventional type of single roof locker occasionally proves too small. Flexibility is easily achieved with a railed enclosure and loose sheet, but the panelled locker is preferred by many operators.

What, then, appears to be required is an expanding locker, and we will describe a method of construction. The locker has a pair of lids meeting at the longitudinal axis, and the sides of the locker are hollow. Between the inner and outer boarding of these sides there is a third board free to slide vertically. The lid is hinged to this centre sliding board.

When the capacity of the locker is to be increased the open lid is grasped and pulled upwards, thus bringing with it the centre board. In order to provide a corresponding extra depth of locker-end, a board, which normally lies flat on the roof, is turned upwards at right angles.

This hinged end then rests directly on the normal locker-end, and it is fastened to the raised side with a hook or other device. The hinged end has a small ledge so that a bearing is available for the Junction of

the lid and the end, at both positions of the locker. • A more elaborate device would include -gearing for

raising and lowering the centre boards simultaneously, also for throwing the hinged ends in and out of engagement.

Patent containers of the expanding variety are now available on the market.

There is a contrast between the large landings, wide treads and convenient ascending handles of a doubledecker's staircase and the devices for giving access to the roof locker of a coach. Space is too valuable for a special staircase, and the only alternative is to increase the safety of the usual iron ladder or steps.

It is considered that the ladder should have a hinged portion so that it may slope appreciably and reach the ground. The design of the top landing is important, because, as a rule, there is nothing to hold, and safety depends on the kind of surface which has to be negotiated.

A suggested design of top landing has cross-wise slats to give a firm foothold, and it is guarded on both sides by a ledge, rail or small upright panel to prevent the feet from slipping sideways. One of these side guards may take the form of a rail about 2 ft. 6 ins. above the roof.

Such a rail would provide a commode handle of convenient height and ensure safety when a heavy bag was being carried. If a fixed rail be considered a disfigurement, it could be supported by means of a jointed stay and folded during the journey, thus being invisible to anyone in the street, and causing no increase in overall height.