MEER SUPS2

Page 89

Page 90

If you've noticed an error in this article please click here to report it so we can fix it.

orm--, 13 1E

WELL-KNOWN TRAILER MAKER nice said that the worth of any component )f a semi trailer could be measured by the ixtent to which it could be neglected and till operate more-or-less satisfactorily. But his is a counsel of expediency which gnores the need to design performance as veil as toughness into an artic. While oughness may be regarded as an essential tailing requirement, good performance is :ssential to safe handling and pays off in the ong run economically.

Rubber may yet be accepted by the najority of trailer makers and operators as he ideal spring material for artics and Iraw-bar trailers. It can give maintenanceree service over long periods and it has a lumber of performance advantages. It is elf-damping, and limited deflection can be iombined with a variable rate to give high oil resistance, laden or unladen, as well as a elatively low rate when the vehicle is unning light.

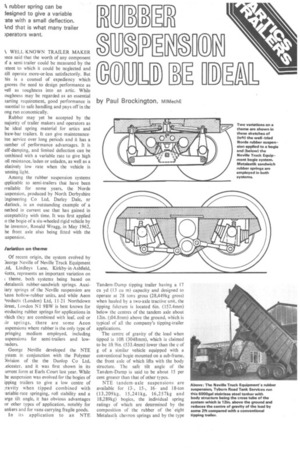

Among the rubber suspension systems ipplicablc to semi-trailers that have been ivailable for some years, the Norde uspension, produced by North Derbyshire =_,ngineering Co Ltd, Darley Dale, nr vlatlock. is an outstanding example of a nethod in current use that has gained in icceptability with time. It was first applied o the bogie of a six-wheeled rigid vehicle by he inventor, Ronald Wragg, in May 1962, he front axle also being fitted with the uspension.

Jariation on theme Of recent origin, the system evolved by lieorge Neville of Neville Truck Equipment Lindleys Lane, Kirkby-in-Ashfield, %Tons, represents an important variation on L theme. both systems being based on detalastik rubber-sandwich springs. Auxiiary springs of the Neville suspension are eon hollow-rubber units, and while Aeon 'roducts (London) Ltd, 11-21 Northdown itreet, London Ni 9BW is best known for iroducing rubber springs for applications in vhich they are combined with leaf, coil or Lir springs, there are some Aeon uspensions where rubber is the only type of pringing medium employed, including uspensions for semi-trailers and low.7)aders.

George Neville developed the NTE ystem in conjunction with the Polymer Xvision of the the Dunlop Co Ltd, ieicester, and it was first shown in its urrent form at Earls Court last year. While he suspension was evolved for the bogies of ipping trailers to give a low centre of ;ravity when tipped combined with ;ariable-rate springing, roll stability and a arge tilt angle, it has obvious advantages or other types of application, notably for ankers and for vans carrying fragile goods.

In its application to an NTE

Tandem-Dump tipping trailer having a 17 cu yd (13 Cu in) capacity and designed to operate at 28 tons gross (28,449kg gross) when hauled by a two-axle tractive unit, the tipping fulcrum is located 6in. (152.4mm) below the centres of the tandem axle about 12in. (;04.8mm) above the ground, which is typical of all the company's tipping-trailer applications.

The centre of gravity of the load when tipped is 10ft (3048mm), which is claimed to be 1ft 9in. (533.4mm) lower than the c of g of a similar vehicle equipped with a conventional bogie mounted on a sub-frame, the front axle of which lifts with the body structure. The safe tilt angle of the Tandem-Dump is said to be about 15 per cent greater than that of other types.

NTE tandem-axle suspensions are available for 13-, 13-, 16and 18-ton (13,209kg, 15,241kg, 16,257kg and 18,289kg) bogies, the individual spring ratings of which are determined by the composition of the rubber of the ' eight Metalastik chevron springs and by the type of auxiliary spring employed. Tandem-axle rate capacities vary between 29,000lb (93,154kg) and 41,000lb (18,597kg) with five rating options.

In the case of the most progressive suspension option of 15 tons (15,241kg), the deflection of the axle from the unladen position to that in which an Aeon auxiliary spring is engaged is 0.75in. (19.05mm), the total and bump deflections of the axle being 2.25in. (57.15mm) and 3M. (76.2rnm) respectively. A load per spring set of 20001b (907.2kg) deflects the axle -tin. (12.7mm); increasing the load to 49001b (2222kg) produces a deflection of lin. (25.4mm) and the deflection is 1.5in. (38.1mm) in the static laden condition with a load of 85001b (3855.6kg).

A load of 13,000lb (5896.8kg) gives a deflection of 2in. (50.8mm) while the full deflection of 2.65in. (57mm) is produced by a load of 16,000lb (7257.6kg). The spring rate increases from 40001b /in. (71.44 /cm) when the vehicle is unliden to 81001b /in. (944.6kg /cm) when laden, the rate fer the final 0.2.5in. (6.35mm) of deflection being 12,0001b /in. (213 kg /cm).

The suspension is based on a pair of walking beams that pivot on the shaft of a central cross-tube, and the Metalastik sPrings are four-layer rubber chevron sandwich units approximately in line with the axles and beam members. Total weight of the bogie is 1 ton 4+cwt (1245kg) complete with mounting pivot pedestals but without wheels.

Movement of the axles and brake reaction are controlled by radius arms mounted on brackets at the centre of the axles and brackets on the cross-tube. This tube carries two platforms inboard of the beam members which are attached to extensions of the body structure in the case of a tipping trailer or to a sub-frame in applications to a tanker or van. The chevron rubbers act in shear and compression, a major part of the load being taken in shear. Scrubbing action of the tyres tends to displace the axles and compress the chevron springs on a diagonal axis to allow self-tracking to an extent that is claimed to be beneficial to tyre life. Self-tracking of the axles is facilitated by the use of ball-jointed radius arms, sealing of the ball joints being provided by Neoprene washers.

Single-axle versions Single-axle versions are available with four load/deflection ratings, the individual spring units of which correspond to those used in equivalent bogie suspensions.. Tandem-Dump trailers equipped with the suspension are available with capacities up to 60 cu yd (45.87 cc m).

In contrast to the NTE bogie suspension, movement of the articulated beams of the Norde system is controlled by sandwich rubber springs, and two pairs of rubbers are used instead of the four of the NTE bogie which are mounted ,above the axles. The bogie running gear can carry up to 20 tons (20,321kg) and the springs have a deflection of 2in. (51mm), the total travel of the wheels being about 6in. overall. Roll stiffness of the suspension is 13,250lb/in. /deg (236.63kg / mm /deg) while the ;veiOrt of the bogi6 is 36Icwt (185.5kg). Corresponding specifications of the Norde single-axle with sandwich rubber suspension comprise a capacity of 10 tons, a spring deflection of 2.5in. (63mm), the same roll stiffness and a weight of 18cwt (914kg).

A single A-frame type of torque arm with conical rubber end bushes is fitted to the single-axle and two similar arms to the bogie, vertical movement of the bogie springs being controlled by centrally mounted outrigged shock absorbers. Also of articulated-outfit interest, a Norde tractive unit bogie has a self-steering axle, the rubber suspension being located relatively close to fixed axle to give a 2 to 1 offset. The semi-trailer bogie has been applied to tipping trailers.

Tyburn Road Tank Services Ltd was one of the first operators to use Norde suspension and helped with development work, the original batch of Norde-equipped vehicles having been in service since 1966. The company now operates 29 vehicles with Norde tandem-axle running gear and 14 single-axle vehicles equipped with the suspension. Mr R. J. Loosley, technical research and development manager, states that maintenance has been "very light indeed" compared with a conventional elliptical or air suspension.

Recent modifications to the tandem suspension include the use of Hyplus stet which has greater strength and weighs les than conventional steels. Both types ar now fitted with a simple type of anti-ro system comprising a bracket and bump sto that obviates excessive roll and stressing c the springs in tension. Ronald Wrag reports that sales of Norde suspensio increased by 75 per cent last year.

Systems in which Aeon hollow-rubbe springs are the sole means of suspensio include a trailing axle type that is availabl as optional equipment on Yor Freightmaster vans. York reports that th suspension is favoured by a number c operators who carry fragile goods, th elimination of high-frequency vibration being a special virtue of the system.

Rubber-only suspensions Other rubber-only suspensions evolve by Aeon include a pivoted arm typ designed for a Pitt 35-ton ultra-low-loadin trailer and a four-unit trailing arm syster (with downward sloping arms) for a light( low-loader. In the first case, thre heavy-duty Aeon rubbers at the front of th arm cushion the load and a single sma rebound rubber is fitted above the arm. cluster of four small rubbers mounted elm to the pivot is used in each of the units ( the trailing-arm suspension.

A number of car-transporter trailers being operated by Carter Engineering C Ltd, of Tamworth, that have Carte designed trailing-arm suspensions wit single Aeon rubbers mounted between tt axles and chassis frame, axle loads varyin between 2 tons and 6 tons. In an apprais of rubber as a suspension medium, Mr 4/ H. Carter says that "it must be exacti tailored to the job; if it is overloaded it ten< to creep and harden". In a tribute to Mc units, Mr Carter said that the hollow type rubber spring provides desirable characteri tics given that it is correctly matched to tt axle load.