A NEW FINAL DRIVE AND A NEW BRAKE,

Page 12

Page 13

If you've noticed an error in this article please click here to report it so we can fix it.

De Dion BoutOn chassis construction has always been noted for its cleverness in design, and in particular for its originality of conception in many details of its constructien. In those days of seeming long ago, when original and distinctive design was the portion of all Idle cars of the first grade and.before the advent of the present epoch:of:standardization for production, and assembly for components—the latter is mainly exemplified by American practice—there were certain features which, in consequence of their excellence, had become almost universally employed, but which were still recognized by the quidnuncs of the industry as De Dion in origin. One detail of chassis construction of outstanding merit which was for a long time the established feature of the De Dion touring car chassis was the rear aide embodying articulated axle shafts for the final drive, the object of this special construction being the elimination of those inefficiencies of the transmission which resulted from undue flexion of the load-carrying axle when under stress.

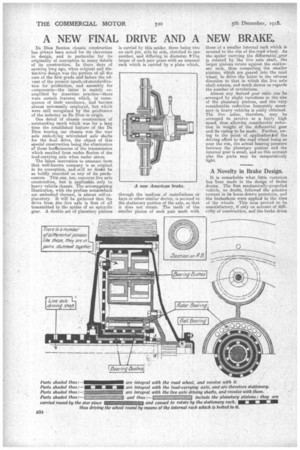

The latest innovation to emanate from that well-known company is as original in its conception, and .will no doubt be as boldly executed as any of its predecessors. This one, too, concerns live axle construction, but is applicable only to heavy vehicle chassis. The accompp.nying illustration, with the profuse noteerwhich are embodied thereon, is almost self-explanatory. It will be gathered that the drive from the live axle is first of all transmitted to the spider of an epicyclic gear. A double set of planetary pinions is carried by this spider, there being two on each pin, side by side, clutched to one another, and differing in diameter. ',The larger of each pair gears with an internal rack which is carried by a plate which, through the medium of castellations or keys or other similar device, is secured to the stationary portion of the axle, so that it does not rotate. The teeth of -the smaller pinion of each pair mesh with

those of a smaller internal rack which is secured to the rim of the road wheel. As the spider carrying the differential :gear is rotated by the live axle shaft, the larger pinions rotate against the stationary rack, thus compelling the smaller pinions, which are geared into the road wheel: to drive the latter in the reverse direction to that in which the live axle shaft rotates, and much slower as regards the number of revolutions.

Almost any desired gear ratio can be arranged by slight variations in the size of the planetary pinions, and the -very considerable reduction frequently necessary in heavy vehicles is easily obtained. The live axles, therefore, may be arranged to revolve at a fairly high speed. thus allowing considerabk reduction in weight of the differential gear and its casing to be made. Further, owing to the point of applicationiof the driving effort to the road wheel being so near the rim, the actual bearing pressure between the planetary pinions and the internal gear is small, and on this account also the parts may be comparatively

A Novelty in Brake Design.

It is remarkable what little variation has been made in the design of brake drums. The first meehanically-propelled vehicle, no doubt, followed the practice current in its horse-drawn prototype, and the brakeshoes were applied to the rims of the wheels. This soon-proved to be unsatisfactory, if only on account of difficulty of construction, and the brake drum as we know it very quickl,y supplanted this arrangement. Except in minor details of construction, the first brake drum was the same as those which are stall used on the most modern types of automobiles. Alterations to the brakeshoes and to the .manner of their application, there have been in great variety. The drum itself differs ofily as to whether it is prepared to receive the shoe externally or internally.

A new typo of brake which is being given considerable publicity in the current American periodicals is therefore of particular interest on this account alone. It appears to have, moreover, several im portant adviinteges as compared with existing practice. It is analogous, in relation to the usual typo of brake, to the plate clutch as compared with the older leather-lined coned component. The drawing which we reproduce illustrates one simple application of the principle embodied in this new construction. Three discs are employed, the centre one being bolted to the wheel, whilst the others are keyed to the axle casing, being thus prevented from rotating, while nevertheless free to slide for a limited distance along the axle. The brake lever acts by rotating the cam, which is clearly shown on the drawing, and this presses the two

outer discs into close contact with the middle one.

Any required amount of leverage may .be afforded to the gear, which acts on the same principle as a screw thread and nut. The areas in contact are much greater than can in ordinary circumstances be provided in the case of the drum type of brake. These surfaces can be still further increased by corrugating the faces of the discs, as, is done m the case of those of the Hele-Shaw clutch. The design offers certain advantages, too, in respect of manufacture, the parts all lending themselves admirably to production in quantity, and preferably as stampings and pressings.