Check your air brakes

Page 58

Page 59

Page 60

Page 61

If you've noticed an error in this article please click here to report it so we can fix it.

THE formidable array of pipes, valves and ancillary components associated with air brake systems tend to make people think air brakes are very complex. But while each individual part is, in itself, an intricate piece of precision engineering, the basic operating principles are quite simple.

Maintaining and repairing these systems, then, doesn't have to be a matter for specialists, provided care is taken and common sense used.

I contacted one of the leading suppliers of air brake equipment, Bendix Westinghouse Ltd, at Bristol, for advice on how to tackle this aspect of vehicle maintenance.

Bendix Westinghouse itself is able to offer kits to overhaul a large number of its products and these include fitting instructions as well as exploded view diagrams.

To back up these kits the company produces two publications, one on introduction to air brake systems and the other a fast-moving parts catalogue giving details of each individual components repair kit number. If required these two booklets are available, together with a typical selection of air brake equipment in detail, all in one publication called Pneumatics for road transport.

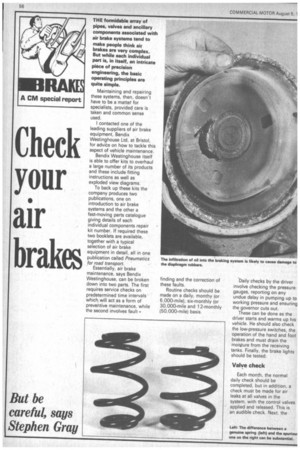

Essentially, air brake maintenance, says Bendix Westinghouse, can be broken down Into two parts. The first requires service checks on predetermined time intervals which will act as a form of preventive maintenance, while the second involves fault finding and the correction of these faults Routine checks should be made on a daily, monthy (or 6,000-mile), six-monthly (or 30,000-mile and 12-monthly (50,000-mile) basis. Daily checks by the driver involve checking the pressure gauges, reporting on any undue delay in pumping up to working pressure and ensuring the governor cuts out.

These can be done as the driver starts and warms up his vehicle. He should also check the low-pressure switches, the operation of the hand and foot brakes and must drain the moisture from the receiving tanks. Finally, the brake lights should be tested.

Valve check

Each month, the normal daily check should be completed, but in addition, a check must be made for air leaks at all valves in the system, with the control valves applied and released. This is an audible check. Next, the mloader and condenser has to )e inspected for signs of )xcessive oil consumption and the automatic drain valves thecked to make sure they're dvorking properly.

At six-monthly intervals the standard monthly checks must be done but should include timing the compressor "pump up" as well as checking the operation of the main system.

Finally, at 12 months it's necessary to carry out all the six-monthly checks, soap and water must be used to look for air leaks. The use of soap and water has the advantage of showing up small inaudible leaks which can be corrected before more serious problems develop.

With spring brake and lock actuator systems: it's important to ensure that not only is the system working but that it is able to produce the necessary braking effort. A Tapley Meter will show an overall deceleration, but ideally, the brakes should be tested on a rolling road dynanometer.

Fault finding

Fault-finding and the rectification of the faults can be more difficult. It's easy enough to tighten a pipe union to cure an air leak, but overhauling a compressor, for example, presents a different situation.

However, probably the understood and badly repaired component of the whole air brake system is the spring brake. A number of dubious rebuilt units are offered by some so-called brake specialists at a very low price and appear very attractive to the operator. More often than not, these units have been repaired without the spring being replaced.

Even more serious than this, though, is the practice of some repairers who have had inferior springs made up. Bendix Westinghouse points out that its springs are made to exacting standards necessary for the work they do.

Many of the spurious springs are distorted (causing the piston to be thrown out of line) and are likely to break under load. For the operator wanting to repair his own spring units a few simple rules should be observed. The first is to buy the correct repair kit for the particular unit. This may sound obvious, but often, the brake unit is in pieces before it's discovered that the wrong kit has been bought! An essential piece of equipment, required before the spring brake is dismantled, is a spring -compressor. Churchill Tools manufactures its MS61 tool which has adae)tors to suit Magnum or remote units. As each section of the spring is dismantled, it should be examined for wear or scoring Any sign of damage must mean replacement of the component — even though it may not be supplied in the repair kit.

During re-assembly, it's absolutely essential to use the correct lubricant where specified. This applies to all repairs carried out on air brake systems. If any detergent is used to clean off parts, it must be thoroughly removed before re-assembly, as it can damage the seals.

General rules

Another general rule, but one particularly applicable to spring brakes, concerns the use of thread tape or thread sealers. In general, says Bendix Westinghouse, these sealers are unnecessary and can cause problems.

Often an excessive amount is used which finds its way into the ports where it solidifies, sealing the inlet and exhaust valves. Alternatively, if the spring brake unit is put on a shelf,the sealer lays at the end of the cylinder and can damage the piston sealing ring as the piston comes up to the end of its stroke.

For those who prefer it, Bendix Westinghouse can supply a back unit, already built up which simply bolts onto the spring brake chamber.

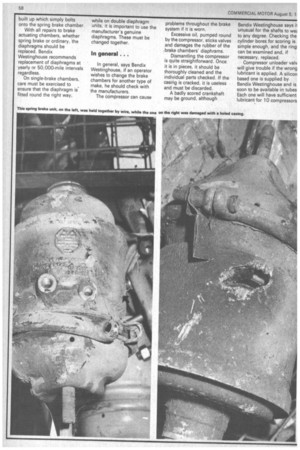

With all repairs to brake actuating chambers, whether spring brake or ordinary, the diaphragms should be replaced. Bendix Westinghouse recommends replacement of diaphragms at yearly or 50,000-mile intervals regardless.

On single-brake chambers, care must be exercised to ensure that the diaphragm is fitted round the right way, while on double diaphragm units, it is important to use the manufacturer's genuine diaphragms. These must be changed together.

In general . .

In general, says Bendix Westinghouse, if an operator wishes to change the brake chambers for another type of make, he should check with the manufacturers.

The compressor can cause problems throughout the brake system if it is worn.

Excessive oil, pumped round by the compressor, sticks valves and damages the rubber of the .brake chambers' diaphrams.

Dismantling the compressor is quite straightforward. Once it is in pieces, it should be thoroughly cleaned and the individual parts checked. If the casing is cracked, it is useless and must be discarded.

A badly scored crankshaft may be ground, although Bendix Westinghouse says ii unusual for the shafts to we to any degree. Checking the cylinder bores for scoring is simple enough, and the ring can be examined and, if necessary, replaced.

Compressor unloader valv will give trouble if the wrong lubricant is applied. A silicon based one is supplied by Bendix Westinghouse and is soon to be available in tubes Each one will have sufficient lubricant, for 10 compressors The rest of the brake system ; fairly easily maintained. Foot alves should not give any -ouble provided, again, that the orrect lubricant is employed. he same applies to check alves and pressure protection alves.

Pipework on today's vehicles ives little problems, but a egular check, to ensure it is vell clipped up, pays dividends. Thecking Suzies regularly is 3Iso worth while and, at the .ame time, trailer coupling

cocks and heads must be inspected for perishing of the rubbers.

Finally, the brake reservoirs can be visually inspected for rust or damage. Any signs of damage necessitates immediate replacement.

Provided care is taken, air brake repairs should be easy enough to carry out. However, the manufacturer's instructions must be obeyed and the correct parts and lubrication used.