A SOLO

Page 46

Page 47

Page 48

If you've noticed an error in this article please click here to report it so we can fix it.

9-tonner with Normal Control

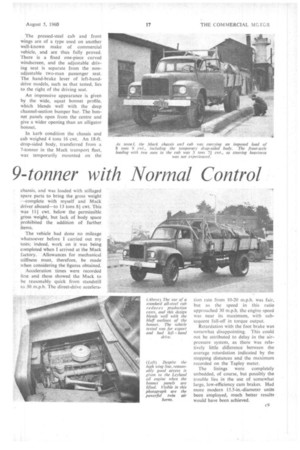

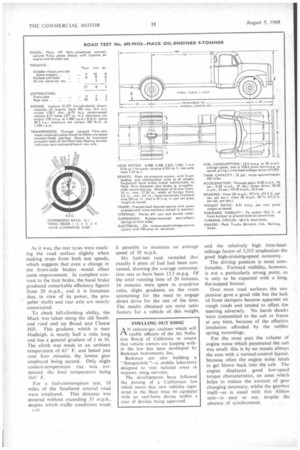

Latest Mack 9-ton Goods Chassis has Normal Control to Give Roomy Cab.' Leyland 0.375 Oil Engine Gives Ample Power with Good Economy By John F. Moon A.M.I.R.T.E.

ALTHOUGH manufacturers in many countries outside the United Kingdom build normalcontrol 14-ton-gross goods chassis to meet an ever-present demand in various parts of the world, few vehicles of this type are made in this country, other than heavy-duty models intended primarily for use with trailers at gross train weights of up to 30 tons or so.

These are not really an economic proposition for solo operation except when intended for dumper roles. A few suitable vehicles are, however, to be found in Britain, and one of them is the Mack H9 9-tonner. The makers, Mack Trucks (Britain), Ltd., are unconnected with the American company bearing a similar name, although they handle replacements for American Mack vehicles in Britain. Apart from goods chassis, the company manufacture heavy-duty axles and gearboxes to special order.

Disc Hand Brake The Mack 9-tonner, whilst basically conventional in concept, has several unusual features, such as a disc transmission hand brake, 171-in.-diameter rear brake drums, and rubbermounted semi-elliptic springs which dispense with the need for frequent maintenance. Ample power is provided by a Leyland 0.375 110 b.h.p. oil engine, mated to an Albion sixspeed overdrive gearbox which gives good gradient performance and a maximum speed of nearly 55 m.p.h. allowing for governor run-up.

A chassis of this type has been road tested and shown to have a good overall performance, apart from slight (.8 braking deficiency, which was aggravated by the newness of the linings and drums. A noteworthy feature of the design is the spacious cab, which suffers no engine intrusion and provides ample accommodation for the driver and two passengers. The test vehicle was one of an order for Turkey, sold through the agents, Mehmet ve Sabahattin Akdogan ve Ortaklari.

Unfortunately, because of styling dictates, the front-wing line is high, and this does little to aid engine accessibility. Nevertheless, all the engine auxiliaries are easy to reach, and when r fitted my fuel-test tank I experienced no difficulty when venting the fuel system, despite the location of the fuel-lift pump low on the left of the cylinder block.

The basis of the Mack H9 is a simple ladder-type frame with +-in.thick side members which have a maximum depth of 9 in. There are seven bolted cross-members. The front and rear semi-elliptic springs are attached to the chassis frame through rubber pads, and their ends are flat, carrying dished plates which give fore and aft location.

The rear axle is a sturdy unit of Mack manufacture, with doublereduction final-drive gearing. The primary reduction is by spiral-bevel gears, whence the drive passes through a set of spur gears with straight-cut teeth. The overall reduction is 7.33 to 1, and the axle carries cam operated leading and trailingshoe brakes actuated by Mack-built diaphragm-type chambers. The linings are 51 in. wide.

Cam brakes are employed also at the front and have a diameter of 16 in., with 21-in.-wide linings. The total frictional area of the front brakes is 151 sq. in., whilst at the rear it is 405 sq. in.

The hand lever acts on a disc brake located at the propeller-shaft centre bearing. The disc diameter is 16 in., and the two pairs of arcuate shoes carry linings with a total area of 122 sq. in. This brake assembly is particularly robust and its power was sufficient to produce a Tapley-meter reading of 90 per cent. when applied from 20 m.p.h.

Marles cam-and-double-roller steering gear is employed, and, as the front-axle loading is under 31 tons, no servo is fitted. Both axles carry Budd 10-stud wheels with 11.00-20-in. (12ply) lug-tread tyres. The pressed-steel cab and front wings are of a type used on another well-known make of commercial vehicle, and are thus fully proved. There is a fixed one-piece curved windscreen, and the adjustable driving seat is separate from the nonadjustable two-man passenger seat. The hand-brake lever of left-handdrive models, such as that tested, lies to the right of the driving seat.

An impressive appearance is given by the wide, squat bonnet profile, which blends well with the deep channel-section bumper bar. The bonnet panels open from the centre and give a wider opening than an alligator bonnet.

In kerb condition the chassis and cab weighed 4 tons 16 cwt. An 18-ft. drop-sided body, transferred from a 7-tonner in the Mack transport fleet, was temporarily mounted on the chassis, and was loaded with stillaged spare parts to bring the gross weight —complete with myself and Mack driver aboard—to 13 tons 8# cwt. This was 111 cwt. below the permissible gross weight, but lack of body space prohibited the addition of further items.

The vehicle had done no mileage whatsoever before I carried out my tests; indeed, work on it was being completed when I arrived at the Mack factory. Allowances for mechanical stiffness must, therefore, be made when considering the figures obtained.

Acceleration times were recorded first and these showed the Mack to be reasonably quick from standstill io 30 m.p.h. The direct-drive accelera (ion rate from 10-20 m.p.h. was fair, but as the speed in this ratio approached 30 m.p.h. the engine speed was near its maximum, with subsequent fall-off in torque output.

Retardation with the foot brake was somewhat disappointing. This could not be attributed to delay in the airpressure system, as there was relatively little difference between the average retardation indicated by the stopping distances and the maximum recorded on the Tapley meter.

The linings were completely unbedded, of course, but possibly the trouble lies in the use of somewhat large, low-efficiency cam brakes. Had more modern I5.5-in.-diameter units been employed, much better results would have been achieved.

As it was, the rear tyres were marking the road surface slightly when making stops from both test speeds, which suggests that even a change in the front-axle brakes would effect some improvement. In complete contrast to the foot brake, the hand brake produced remarkable efficiency figures from 20 m.p.h., and it is fortunate that, in view of its power, the propeller shafts and rear axle are stoutly constructed.

To check hill-climbing ability, the Mack was taken along the old Southend road and up Bread and Cheese Hill. This gradient, which is near Hadleigh, is nearly half a mile long and has a general gradient of 1 in 16. The climb was made in an ambient temperature of 61° F. and lasted just over four minutes, the lowest gear employed being second. Only slight coolant-temperature rise was evidenced, the final temperature being 164' F.

For a fuel-consumption test, 10 miles of the Southend arterial road were employed. This distance was covered without exceeding 33 m.p.h., despite which traffic conditions made

(.10

it possible to maintain an average speed of 30 m.p.h.

My fuel-test tank revealed that exactly 6 pints of fuel had been consumed, showing the average consumption rate to have been 13.3 m.p.g. Of the total running time of 20 minutes, 16 minutes were spent in overdrive ratio, slight gradients on the route accounting for the need to engage direct drive for the rest of the time. The results obtained are most satisfactory for a vehicle of this weight,

and the relatively high time-loadmileage factor of 5,355 emphasizes the good high-cruising-speed economy.

The driving position is most comfortable. Forward visibility, however, is not a particularly strong point, as is only to be expected with a long, flat-topped bonnet.

Over most road surfaces the suspension gave a good ride but the lack of front dampers became apparent on rough roads and tended to affect the steering adversely. No harsh shocks were transmitted to the cab or frame at any time, because of the effective insulation afforded by the rubber spring mountings.

For the most part the volume of engine noise which penetrated the cab was small: this is by no means always the case with a normal-control layout. because often the engine noise tends to get blown back into the cab. The engine displayed good low-speed torque characteristics, an asset which helps to reduce the amount of gear changing necessary, whilst the gearbox itself—as is usual with this Albion unit—is easy to use, despite the absence of synchromesh.