Cheap to Buy and to Operate

Page 46

Page 47

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

Says John F. Moon,

A.M.I:R.T.E. L" initial cost, £.5 annual tax and a low fuel-consumption rate make the new Reliant 5-cwt. van the most economical vehicle in its class to have passed into the hands of The Commercial Motor for testing. The unladen weight of under 8 cwt., has, however, not been achieved without introducing certain utility measures.

Taken generally, the new Reliant embodies sound engineering principles and is as safe to handle as some of its larger four-wheeled contemporaries, whilst its compactness allows it access to spaces which would otherwise be prohibitive.

The specification of the standard 42-cu.-ft. van includes plastics side and roof panels, the material used being glass-fibre reinforced polyester resin to which are bonded hardwood framing members, thereby reducing the number of joints in the complete body. Although the rear and cab doors and the front panelling are

made of light-alloy sheet, the van is the first British commercial vehicle to go into quantity production with so high . a percentage of plastics body panelling.

Another unusual feature of the body lies in the use of Pop rivets for attaching various panels and part of the gutterings to the main timber frame. This speeds up assembly and helps to reduce weight. The van has a similar chassis to that used in the Reliant Regal four-seat private car, the only difference being that slightly. stronger rear springs are fitted on the commercial version.

The power unit is a 747 c.c. side-valve petrol engine which c8 has been derived from a famous and well-tried unit as used for many years by another car manufacturer. It has full force-feed lubrication, shell bearings and separate block and crankcase. The engine cannot be set forward in the frame as in a fourwheeled chassis and this necessitates a large cowl inside the driving compartment. The cowl is a plastics moulding.

A rarity these days is the use of a crash-type four-speed gearbox, but easy changes are possible and double de-clutching is necessary only when changing down. The short gear lever enables changes to be made as quickly as with many synchromesh units.

Welding is used throughout the assembly of the chassis frame, which consists basically of box-section sidemembers and tubular cross-members. A conventional steering box is linked to the front wheel through a system of relay levers. When driving a vehicle with a single front wheel there is no appreciable difference between it and a conventional chassis, except for the commendable feature that the steering is not so greatly affected by uneven road surfaces. Cornering need cause no worries, for the Reliant is as stable as any van with a wheel at each corner.

The test vehicle was lent to mc by Glanfield Lawrence (London), Ltd., 28-32 Highbury Corner, London, N.5, Reliant distributors for the London area. The van was in standard condition except for the addition of a passenger, seat, interior mirror and demister. The payload was in the form of five sacks of cement totalling 5 cwt.

Within a minute or two of starting, I was quite at home with the van, but regretted the lack of opening side-windows, which prevented me from giving hand signals. Semaphore direction-indicators are fitted, but these are forward of the windscreen, in the side panelling, and are not readily observable from following vehicles.

The engine pulled well and once the oil in the gearbox had become circulated I was able to make quick and silent changes both up and down. After half-an-hour of London traffic I began to feel distinctly warm and once again regretted the inadequate ventilation provided by the flexible side-screens.

The lower-rear corners of both side screens can be propped open a matter of some 6 in., but there are

no other panels which can be opened while the vehicle is on the move. The provision of hinged vents in the scuttle. would help to increase the interior ventilation.

Most of my tests were made in the Birmingham area and the run from London to Birmingham gave me an excellent opportunity of assessing road-holding and general performance. The van has a top speed of 58 m.p.h., as shown by the accurate speedometer, and the engin sounds happiest when cruising ar 45-50 m.p.h.

Above 40 m.p.h. there is sufficient draught forced through the radiator stack. to keep the engine cool in normal weather, and the overheating tendenCieS which the unit showed when engaged on 'town Work disappeared on the openroad.

Engine Noise Pronounced The noise of the -engine was slightly greater than is currently accepted on small vehicles.I /nit this down to the thin plastics of which the cowling was formed and the lack Of an air-Cleaner on the carburetter intake, coupled with the proximity of the power unit to the driving position.

At relatively high speeds the van was perfectly stable and controllable, except for a suspicion of oversteer, which was MOst noticeable when ov.-A-taking other vehicles. The high gear ratio of the steering (the number of turns on the wheel from lock to lock is l) and the overloaAng of the rear tyres by about 1--cwt. each when running at the recommended'pressure of 24 p.s.i.,

contributed to this effect. A partial cure was made by increasing tyre pressures to 28 psi. and the directness of the steering became less apparent as familiarity with the vehicle grew.

. Rear suspension was on the soft side when laden and . a trifle hard when unladen. With a load aboard, a limited amount of sway was apparent,

which would tend to accentuate the oversteer characteristics.

My normal testing-ground in the Solihull area was used for braking and acceleration trials and the good pulling-power of the engine was noticeable when making the directdrive tests. It was possible, in fact, to engage top gear at 7 m.p.h. and to accelerate smoothly from that speed with no sin of harshness in the transmission.

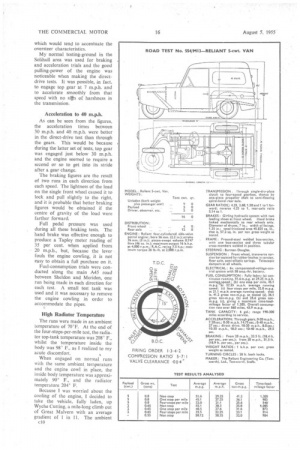

Acceleration to 40 m.p.h.

As can be seen from the figures, the acceleration times between 30 mph. and 40 m.p.h. were better in the direct-drive test than through the gears. This would be because during the latter set of tests, top gear was engaged just below 30 m.p.h. and the engine seemed to require a second or so to get into its stride after a gear change.

The braking figures are the result of two runs in each direction from each speed. The lightness of the load on the single front wheel caused it to lock and pull slightly to the right, and it is probable that better braking figures would be obtained if the centre of gravity of the load were farther forward.

Full pedal pressure was used during all these braking tests. The hand brake was effective enough to produce a Tapley meter reading of 35 per cent. when applied from 20 m.p.h., but, because the lever fouls the engine cowling, it is not easy to obtain a full purchase on it.

Fuel-consumption trials were conducted along the main A45 road between Sheldon and Meriden, one run being made in each direction for each test. A small test tank was used and it was necessary to remove the engine cowling in order to accommodate the pipes.

High Radiator Temperature The runs were made in an ambient temperature of 70°F. At the end of the four-stops-per-mile test, the radiator top-tank temperature was 208° F., whilst the temperature inside the body was 98° F., as I realized to my acute discomfort.

When engaged on normal runs with the same ambient temperature and the engine cowl in place, the inside body temperature was approximately 90° F., and the radiator temperature 204° F.

Because I was worried about the cooling of the engine, I decided to take the vehicle, fully laden, up Wyche Cutting, a mile-long climb out of Great Malvern with an average gradient of 1 in 11. The ambient c10

temperature was 76° F. and the climb was made in seven minutes, mainly in third gear. At the top of the hill the radiator temperature was 212° F., and as soon as the filler cap was removed to take the temperature the water began to boil furiously, haVing been prevented from doing so before by the pressurized cooling system.

For use in temperatures over 70 F. the system is hardly adequate. This engine is not a cool-running unit at the best of times, and the shielding of the radiator by the heavily mudguarded front wheel and the decorative bonnet and frontal valances does not help.

Side Windows Removed 1 had taken the precaution of removing the side windows before setting out for the Malverns and this made driving more bearable. Removal of the windows occupied five minutes each, and this time included replacing the aluminium capping strips along the top of each door. Without the windows, however, it is not possible to lock the vehicle, so this was only a temporary cu-e.

The descent was intended to be a brake-fade test, but the presence of a number of slow-moving vehicles prevented me from maintaining a high enough speed to warm up the brakes thoroughly, so no fade was noticeable at the bottom of the hill.

A point about which I was mine too happy concerned the ability of the driver or passenger to close the

doors from inside because of the lack of door-pulls. It also seems unnecessary to supply three different keys to -the vehicle, one for the ignition, another for the driving door and a third for the rear doors.

'1 he smallness of the van has many advantages, not the least being its low loading height and the small turning circle. The vehicle can be turned round quite comfortably in the width of an average road. These features also simplify parking.

The plastic bodywork, in addition to contributing towards the low price and lightness of the van, is also easy to repair in the unlikely event of a panel becoming broken.

Before I made the brake tests, I adjusted the brakes. This task took me 11 minutes, each wheel being jacked up with the screw jack provided in the tool kit.. There are two hexagon-headed adjusters on the front back-plate, but these were not easy to find because they were partly hidden under the stub-axle casting.

A single square-headed brake snail adjusts each rear brake, but no spanner which will fit these adjusters is provided in the tool kit. A small slot cut in the end of the plugspanner handle would suffice for this operation.

To change the off-side rear wheel took 7,1 minutes. The spare wheel is stowed under the bonnet on the flat deck above the front wheel and is retained in place by two wheel. nuts. The battery is also under the bonnet, where it is instantly acces

sible and well shielded from dirt and moisture. To top up the electrolyte and to check its specific gravity was a 21-minute job.

There are 14 greasing points (although no grease gun is-provided) and to attend to these took me six minutes. The mechanical fuel pump has a disc filter which can be removed and cleaned in two minutes. The three jets in the SoIex carburetter can be inspected and cleared in three minutes.

Tappets Not Adjusted 1 did not attempt to adjust the tappets as the engine was hot and the tappet cover is very close to the exhaust manifold. It would be necessary, however, to remove the petrol pump and to adjust the three foremost tappets would call for special short spanners, or the near-side engine panel would have to be detached.

Removal, cleaning and replacement of three of the sparking plugs occupied six minutes. No. 1 plug, however, is difficult to reach, because it is masked on each side by the distributor and the dynamo, and from above by the top water hose.

The van sells for £345 9s. 10d., including £40 9s. 10d. purchase tax. It is thus the cheapest commercial vehicle produced in Great Britain. By ignoring the 8-cwt. weight limit and incorporating a few detail refinements, the van could be made even more attractive for local delivery work.