Scavenging System for Blown Engines

Page 56

If you've noticed an error in this article please click here to report it so we can fix it.

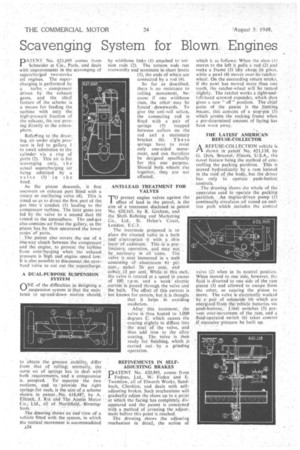

PATENT No. (121,695 comes from Schneider et Cie., Paris, and deals With improvements in the scavenging of supercharged two-stroke oil engines. The supercharging is performed by

a turbo comPressor driven by the exhaust gases, and the chief feature of the scheme is a means for feeding the turbine with only the high-pressure fraction of . the exhaust, the rest pass-. ing directly to. the atmoSphere.

Refuting to the draw-, jug, air under slight pressure is fed to gallery 1 to await admission to the cylinder via a ring of ports (2). This air is for scavenging only, " t Ii e actual supercharging air being admitted by a valve (3) in the head.

As the piston descends, it first uncovers an exhaust port fitted with a rotary or oscillating valve (4). This is timed so as to direct the first part of the. gas into 'a conduit (5 leading to the compressor turbine. The later gases are led by the valve tri a second duct (6) vented to the atmosphere. The end-gas also contains ar from the gallery; as the piston .has by then uncovered the lower

series Of ports.. • .

The patent also covers the use of a One-way clutch betWeen the compressor' and the engine, to prevent the turbine from oVereharging when 'the. exhaust pressure is Trigh and engine speed low: It is also possible to'clisconneet thestverhead valve to cut out the supercharge.

A DUAL-PURPOSE SUSPENSION SYSTEM:.

O1-INE of the difficulties in designing a .suspension system iS:that the resistance to up-and-down motion should, to 'obtain the greatest Stability, differ from that of rolling; nOrmally, the same set of springs has to deal with both requireinents, -and -a compromise is. accepted. To" Separate the two motions. and to ''pkovide the right springs ,,for each, it the aimofa scheme shown in patent-No. 61.8,487, by A. . Elleoek,.J. Rix and. The Austin Motor Co., Ltd., al of. Northfield,Binning

hank • — The &awing shOW4 an end -view of a vehicle fitted with the system, in which the vertical movement is accommodated A34 by wishbone links (I) attached to 'torsion rods (2). The torsion rods run rearwardly and terminate in short levers (3), the ends of which arc connected by a rod (4).

So far as described, there is no resistance to rolling movement, because if one wishbone rises, the other' may be forced downwards. To give the-anti-roll action,, the connecting rod is fitted with a pair of springs (5) trapped between collars on the rod än l a stationary bracket (6). . These springs have to resist only one-sided movement, and can therefore be designed Specifically for this one purpose. Should both wheels rise. together, they are not affected.

ANTI-LEAD TREATMENT FOR VALVES

'TO protect engine valves against the J. effect of lead in the petrol, is the aim of a treatment disclosed in patent No. 620,165, by R. Graham, and the Shell. Refining and Marketing Co., Ltd.. St. Helen's Court, London.' E.C.3..

The treatment prciposed is to place the cleaned valve, in a bath and` electroplate --it with a thin layer' of cadmium: This -is 'a preliminary, operation, and may not be necessary in all 'caSes, The Valve is next immersed in a melt consisting of • aluminium .61 per ciente. /ticket26 per cent, and cobalt 13 per cent. While in this melt, the valve is rotated at a speed in excess of 100, r.p.m. and a weak electric :current is passed through the valve and the b41-1. The effect of this current is not known for certain, but it is thought

that it helps in avoiding oxidation.

After, this treatment, the valve is then heated to 1,000 degrees C. which causes the coating slightly to diffuse into ' the steel of the valve, and thus add iron to the alloy coating. The Valve is then ready for finishing, which carried out by a grinding operation.

REFINEMENTS IN SELFADJUSTING BRAKES DATENT No. 620,995, comes from Fodens, Ltd., W. Foden and E. Twernlow, all of Elworth Works, Sandbach, Cheshire, and deals with selfadjusting brakes. Such mechanisms will gradually' adjustthe shoes up to a point ' at which the facing has completely disappeared and the patent is concerned with a method of arresting the adjustMein before this point is reached.

The drawing shows the adjusting mechanism in detail, the action of

which it as follows: When the shoellr moves to the left it pulls a rod (2) and rocks a frame (3) idly about itS piVoi. while a pawl (4) moves over itsratchetwheel. On the succeeding return stroke, if the pawl has moved more than one tooth, the ratchet-wheel will he turned slightly. The ratchet works a right-and'left-hand screwed expander, which then gives a new off" position. The chief point of the patent is the limiting Means; this consists of a stop-pin which 'afrets the rocking. frame when a pre-determined amount of facing has been worn away.

THE LATEST AMERICAN REFUSE-COLLECTOR

A . REFUSE-COLLECTION vehicle is ii shown in patent: No. 62L118„ by G. Duis, Streatoi-, Illinois, U.S.A., tha novel feature being the method of colt-, trolling the packing partition. This is moved hydraulically by a rain located in the roof of the body, but the driver has only tooperate push-button

controls. , The drawing shows the whole of the apparatus used to operate the packing partition. An angine-driven pump (1) continually circulates oil round an endless path which includes the control

valve (2) when in its neutral position. When moved to, one 'side, how'ever, the fluid is diverted to one side of the ram . piston (3) and allowed to escape from .the other, so causing the piston to move. The valve is electrically worked by .a.--,pair of solenoi,d.s. (4) which are 'energizecl'froin the vehicle batteries via Push-buttonse .Litnit switches (5) prevent over-rnovement of the ram, and a fluid-operated :switch (6) takes control 'exeessive-pressure be built tip.