HINTS ON MAINTENANCE.

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

550.—Freeing Choked Greasers.

A common cause of excessive wear on shackle bolts is failure a lubrication, owing to the grease not being able to reach the wearing surfaces. The block usually occurs at the outlet end of the grease channel. This is often through the presence of dirt or rust, which, owing to the movement between the shackle bolt and sluing eye is rubbed to a ,powder, which mixes with

• the grease and forms a stiff paste. This paste soon becomes hard, and acts almost as a cork, which prevents the grease cup from being screwed on more than a few threads. Attempts to force it farther sometimes result in stripping the threads, which are invariably brass and, consequently, rather soft. One method of overcoming the difficulty is shown in the illustration. A pin or bolt, which must be a good fit in the head of the shackle bolt, should be forced in for a sufficient distance to permit it to support itself. It should then be given a sharp blow with _ • a hammer. This should be repeated two or three times, after which it will usually be found that the solidified grease has been forced between the bolt and the inner surface of the spring eye.

Once the greaser is free, it should be charged and screwed up several times. A repetition of the trouble can be preyented by giving the greaser a turn at fairly krequont intervals.

551.—Curing Flooding on the Solex Carburetter.

Users of Solex carburetters who may have trouble with overflowing from the jet are sometimes puzzled as to how this can be cured, owing to the fact that the construction of the control valve differs from that 'on the usual type, having no toggle weights and collar.

Adjustment for the petrol level cannot be carried out in the ordinary manner, but one or other of the following two methods will probably effect a cure. (1) A spot of solder dropped on the end of the needle should have the desired effect of lengthening it, but the thickness of the solder required can only be determined by actual experiment, as, obviously, this will depend on the amount of leakage. Care should be taken to see that the needle is not made too long, or the jet level will he too low, and difficult starting will probably result. (2) Remove the needle and mating complete from 1346 the upper half of the float chamber and fit a thin fibre washer, such as is used on the plugs of the Zenith, carburetter and replace the seating. Here again the thickness of the washer will depend on the overflow.

It is possible 'that the leakage may not be due to the length of the needle, but by irregularities in the valve or seating. In any case, it is advisable to true the face of the needle and to grind it in position, either with Very fine carborundum or with powdered pumice. The actual bearing should be not much more than a hairline.

552.—Refacing the Clutch Stop of a Karrier.

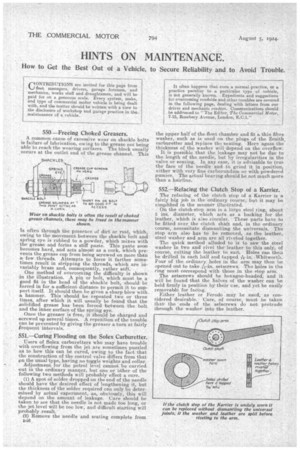

The refacing of the clutch stop of a Karrier is a fairly big job in the ordinary Course, but it may be simplified in the manner illustrated.

• On the clutch-stop arm is a large steel ring, about 5 ins. diameter, 'which acts as a backing for the leather' which is also circular. These parts have to be fitted over the clutch shaft and, in the ordinary course, necessitate dismantling the universals. The stop arm also has to be removed, as the leather, steel Washer and arm are all riveted together.

The quick method alluded to is to saw the steel washer in two and rivet the leather to this only, of course, cutting the. leather to suit. Holes can theii be drilled in each half and tapped ?T--in. Whitworth. Four of the ordinary holes in the arm may then be

opened out to take setscrews. The holes in the ring must correspond with those in the stop arm. The setscrews should be hexagon-headed, and it will be found that the halves of the washer can be held firmly in position bY their use, and yet be easily removable for facing. Either leather or Ferodo may be used, as considered desirable. Care, of course, must be taken that' the • ends of the setscrews do not protrude through the washer into the leather_