POINTERS ON NUTS, BOLTS AND WASHERS.

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

Useful Information which Should Prove of Special Interest to the Designer and Repairer of Commercial Motor Vehicles.

THE FIRST object in providing a nut and bolt in any mechanical arrangement is usually to ensure the clamping together of two parts. That nuts and bolts do not always fulfil this functionds too well known, especially in vehicles running on solid tyres. This failure on their part is usually due to vibration, which can be counteracted, so a little discussion on the subject may be beneficial. From the designer's point of view, and also from the repairer's point of view, the subject is equally of interest.

Taking the designer's interest first, there are many paints which are worthy of consideration in selecting the most suitable bolts, nuts and washers for bolding various parts together, The Whitworth pitches were designed many years ago. when high-speed machinery was almost unknown. They have been found far too coarse and, therefore, unsuitable for motor work and, in most cases, the British standard fine thread is now being used in the motor trade.

Itis the practice of some engineers in the motor trade to abandon the sizes of heads and nuts set down by Whitworth, on account. of the large bosses rendered necessary by such heads, and to replace them with heads of a smaller size. In many cases a On. nut. is fitted to a g-in. bolt, and so on down the scale of the various sizes. This practice, undoubtedly, tends to make things look neater, and for some parts answers well enough. For such parts, however, as those which have very severe strains to contend with it is net good. For really heavy duty there is no doubt that Whitworth was right, and that the larger surface of head and nut is a safeguard against failure. Fig. l shows the effect of using too small a head and nut. The metal has crushed down and allowed the bolt to start working in its hole, Any working or hammering of this sort soon makes matters worse, and should not be allowed to start.

For parts which receive severe side strains the fit of the bolt in its hole should never be relied upon as a means of securing such a part as a bracket to a side frame. Taper steady pins will relieve belts from such strains and can be kept tight-, as. owin.g to their taper, they can be driven in so as to ensure no possibility of working. In some cases a flange can be thrown up so as to lodge on the edge of a side frame, and so enable the bolts to perform only the duty for which they are designed, namely, the holding of parts together. The plan shown in Fig. 2 has been found very useful in holding parts from relative movement in holding sprocket rings to bolts it has proved particularly useful. When making a jig it is easy to put a few extra holes of the same size as the bolts to be employed. These holes can be enlarged on their inner side by means of .a common pin drill. Cheese-shaped pieces can be formed in automatic machine tools and dropped. into the recesses formed for them. This plan is particularly useful to repairers when some parts have been working on the bolts and the boles so worn that new bolts will no longer fit. The parts can be put together and then drilled right, through; they can then be taken apart and the pin drill used.

-The ordinary lengths of spanners were settled when only iron bolts were used It might be well to provide the men employed On assembling with longer spanners so that they can tighten up the nuts on new work more securely. In many cases vehicles leave the works with many of the nuts insufficiently tightened. This is the primary cause of much trouble through bolts coming loose. When one sees a man on the railway line tightening up fish-plate nuts with a spanner some 4 ft. in length, the ordinary spanners do not appear to be lone enough.

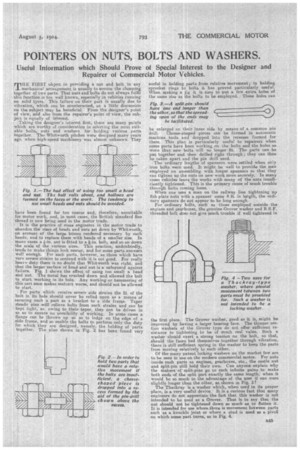

For ordinary bolts, such as those employed outside the engines and gearboxes, the genuine Grover washer and B.S.F. threaded bolt does not give much trouble if well tightened in the first place. The Grover washer, good as it is, might be improved by having a larger bearing face. The thinner section washers of the Grover type do not offer sufficient resistance to tightening to he of much real value. Such a washer should exert a strong tension on the bolt, so that, should the faces bed themselves together through vibration, there is still sufficient spring in the washer to keep the parts from moving relatively to each other.

Of the many patent locking mashers on the market few are to be seen in use on the modern commercial motor. For nuts inside such parts as engines, gearboxes, etc., the castle nut and split-pin still hold their own. Can anyone explain why the makers of split-pins go to such infinite pains to make both ends of the split part exactly the same length, when, it would be so mach to the advantage of the user if ono were slightly longer than the other, as shown in Fig. 3? The Tharkray is a washer which, when used in its proper place, is a-very useful device. It is a curious fact that many engineers do not appreciate the fact that this washer is not intended to be used as a Grover. That is to say that the nut should not be tightened down so much as to flatten it. It is intended for use where there is movement between parts such as a knuckle joint or where a stud is used as a Pivot on which some part turns, as in Fig. 4.