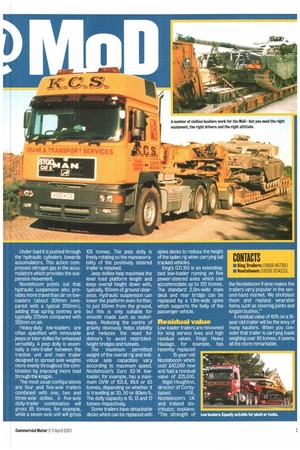

Hauliers working in the defence sector can field standard vehicles,

Page 32

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

but there is plenty of scope for more specialist kit. Sharon Clancy looks at what to buy if you plan to haul explosives and armoured fighting vehicles to the front line.

auhers working for the MoD move everything from boxes of parts to main battle tanks.

Using civilian hauliers is attractive to the MoD because many of its transport requirements are the same as any other multi-site organisation. The MoD benefits because it gets cheaper transport rates; the hauliers maximise utilisation of their equipment.

Standard vehicles

Many consignments can be carried on standard vehicles including curtainsiders, rigids and even CDVs—Lex Transfleet and Ryder both have contracts to supply and maintain sections of the Ministry of Defence's "white fleet" of non-battlefield vehicles. But some loads do require specialist equipment.

Hauliers which are carrying ammunition must be registered to carry explosives, and vehicles used to transport it must meet the ADR EXII and EXIII regulations for explosives.

All tractive units must be equipped with shielded electrical systems to eliminate the risk of sparks triggering an explosion with reinforced rear cab walls to protect the driver if something does go wrong.

Even the transport of heavy tracked vehicles can be contracted out to heavy haulage specialists: low-loader rigs designed to carry 100-tonne cranes are equally capable of carrying tanks and other heavy equipment.

Hydraulic steering and suspension are standard features on low-loaders above 60 tonnes; powered hydraulic steering on all axles is essential to increase manoeuvrability and to minimise tyre wear. Steering axles contribute enormously to the manoeuvrability of a low-loader, says Mark Carrington, managing director of King Trailers: "Depending on length, a hydraulically steered low-loader can negotiate corners and bends almost as easily as a regular 16.5m C&U combination."

The hydraulic steering gear on King's GT Series low-loaders responds to signals from a sensor on the kingpin which transmits the articulation angle. During slow, tight-radius turns a wanderlead control can be used to override the steering-lock angle. Manoeuvrability can be further improved when partladen by raising the rearmost axle off the ground.

Hydraulic suspension is preferred to air on heavy-duty lowloaders, mostly for the enhanced stability it gives. With air suspension the airbag changes shape as the air is compressed, increasing lateral roll. Hydraulic suspension can eliminate this problem because oil is not compressible. Under load it is pushed through the hydraulic cylinders towards accumulators. This action compresses nitrogen gas in the accumulators which provides the suspension movement.

Noote boom points out that hydraulic suspension also provides more travel than air on lowloaders (about 300mm compared with a typical 200mm), adding that spring centres are typically 275mm compared with 252mm on air.

Heavy-duty low-loaders are often specified with removable jeeps or inter-dollies for enhanced versatility. A jeep dolly is essentially a mini-trailer between the tractive unit and main trailer designed to spread axle weights more evenly throughout the combination by imposing more load through the kingpin.

The most usual configurations are four and five-axle trailers combined with one, two and three-axle dollies. A five-axle dolly-trailer combination will gross 85 tonnes, for example, while a seven-axle unit will gross 105 tonnes. The jeep dolly is freely rotating so the manoeuvrability of the positively steered trailer is retained.

Jeep dollies help maximise the level load platform length and keep overall height down with, typically, 150mm of ground clearance. Hydraulic suspension can lower the platform even further, to just 50mm from the ground, but this is only suitable for smooth roads such as motorways. Reducing the centre of gravity obviously helps stability and reduces the need for detours to avoid restrictedheight bridges and tunnels.

The maximum permitted weight of the overall rig and individual axle capacities vary according to maximum speed. Nooteboom's Euro 83-14 lowloader, for example, has a maximum GVW of 103.8, 89.6 or 83 tonnes, depending on whether it is travelling at 30, 50 or 80km/h. The dolly capacity is 15, 13 and 12 tonnes respectively.

Some trailers have detachable decks which can be replaced with spine decks to reduce the height of the laden rig when carrying tall tracked vehicles.

King's GTL150 is an extendingbed low-loader running on five power-steered axles which can accommodate up to 120 tonnes. The standard 2.9m-wide main deck and rear bridge can be replaced by a 1.9m-wide spine which supports the belly of the passenger vehicle.

Residual value

Low-loader trailers are renowned for long service lives and high residual values. Kings Heavy Haulage, for example, has recently replaced a 15-year-old Nooteboom which cost £42,000 new and had a residual value of £25,000.

Nigel Houghton, director of Corby based HSE, Nooteboom's UK and Ireland distributor, explains: "The strength of the Nooteboom frame makes thz trailers very popular in the second-hand market. We shotblast them and replace wearab4 items such as steering joints an kingpin bushes."

A residual value of 40% OP a 15 year-old trailer will be the envy o many hauliers. When you con sider that trailer is carrying load weighing over 80 tonnes, it seem all the more remarkable.