We can all agree to no smokin

Page 134

Page 135

If you've noticed an error in this article please click here to report it so we can fix it.

Exhaust fumes from vehicles in the workshop is a real problem. Colin Sowman looks at a new product that might help

In Smoke created by starting up a cold diesel engine is always unpleasant. When it is produced in the confines of a workshop it is even worse and may contravene the Control of Substances Hazardous to Health (COSHH) Regulations. Engines, however, do have to be started in the workshop to be tested or to move vehicles. A new product, called the EHC exhaust cleaning system, may be useful to workshop managers in dealing with this problem.

The system consists of two sizes of filter, one for engines up to 2.5 litres, the other for larger engines and are marketed by Metro Chem. Each filter is made up of spun glass fibres and graded charcoal with another very fine spun glass matt where the gasses exit. We asked BRS Southern to try the filters on our behalf in a general workshop environment and also talked to an existing user.

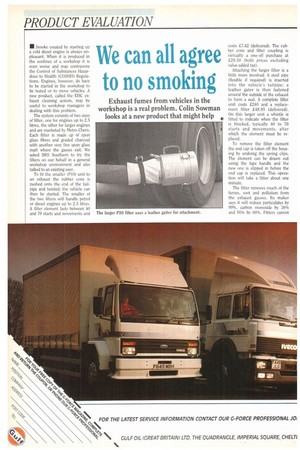

To fit the smaller (P10) unit to an exhaust the rubber cone is pushed onto the end of the tailpipe and twisted; the vehicle can then be started. The smaller of the two filters will handle petrol or diesel engines up to 2.5 litres. A filter element lasts between 40 and 70 starts and movements and Costs 17.42 (delivered). The rubber cone and filter coupling is virtually a one-off purchase at £29.50 (both prices excluding value-added tax).

Attaching the larger filter is a little more involved. A steel pipe (flexible if required) is inserted into the vehicle's tailpipe; a leather gater is then fastened around the outside of the exhaust to form a seal. A complete filter unit costs £240 and a replacement filter 148.95 (delivered). On this larger unit a whistle is fitted to indicate when the filter is blocked, typically 40 to 70 starts and movements, after which the element must be replaced.

To remove the filter element the end cap is taken off the housing by undoing the spring clips. The element can be drawn out using the tape handle and the new one is slipped in before the end cap is replaced. This operation will take a fitter about one minute.

The filter removes much of the fumes, soot and pollution from the exhaust gasses. Its maker says it will reduce particulates by 99%, carbon monoxide by 30% and NOx by 60%. Fitters cannot say if those figures are correct but all those we spoke to were impressed by how well the filter worked. There are, however, strengths and weaknesses in the system and these were pointed out by our testers.

Municipal vehicle and bus builder Dennis has been evaluating the larger filter for about two months, using it on the production line, road-test shop and its major engineering workshop. Brian Norman is service manager of Dennis's south-east depot and has tried the L20 filter. His workshop is used for major work with vehicles often spending a week at a time in the shop, so movements are limited.

£10,000 estimate

However, estimates for installing an extractor system were above £10,000 — even that would not solve all Norman's problems. When manoeuvring vehicles in, out and around inside the shop it is impossible to connect up to a static extractor, he says.

By using the filter he has saved the cost of installing an extractor system for what is only occasional use arid the vehicles can be moved around while inside without filling the place with fumes.

FIRS Southern's Guildford depot has many vehicle movements each day and is, perhaps, more representative of most workshops. The modern workshop already has exhaust extraction equipment installed and so was not suffering the problems or the impending bill of Dennis. Overnight about 10 vehicles are parked in the workshop, most of which have to be driven out before the day's work starts and others brought in again that night.

Area engineering development manager John De Freitas gives his assessment. To get the vehicles out each morning, the doors have to be opened and most of the fumes go out with them. If a filter were put on each time then two refills would be used in a week, costing about £5,000 a year (although bulk order discounts would bring this sum down). This is expensive for a workshop that already has exhaust extraction equipment.

His fitters found that fitting the larger filter (13201 was not too easy because the Volvos that run out of the depot (and the filter was developed by Volvo engineers) have exhausts that end in the centre of the chassis. This means crawling under the vehicle to fit the filter — this is also true of static extractors.

During the test the filter was attached to the exhaust of a customer's vehicle that had been fitted with a secondhand engine. The fitter thought that it was going to be smoky and that this was a very good test, said De Freitas. His fitter was right and was also pleasantly surprised at how well the filter worked. While De Freitas will not be equipping each fitter with a filter, he feels that there is a place for the equipment. Barry Thomson, engineering manager at Guildford, was as impresed as his fitters. "If there was an engine running the filter was being used," he said. He found it particularly useful for the rolling road brake test. But he would like the filter to be fitted with a chain to attach it to the chassis in case a vehicle drives off with it still fitted. 1 le has given the filter the highest level of praise by requesting that one is purchased.

Under the COSHH regulations the employer must make provisions for removing excessive diesel exhaust fumes even though they are not potentially lethal in the way of those from petrol engines. Use of these filters would be as acceptable to the inspectors as the normal static extractors.

Metro Chem is looking for agents for its products.

NIE I IV) (HEN 146