SAVING WEIGHT IN COMMERCIAL BODYWORK.

Page 46

Page 47

Page 48

If you've noticed an error in this article please click here to report it so we can fix it.

Useful Suggestions for Enabling the Weight of Different Types of Goods-carrying Body to be Materially Reduced.

THE saving of weight in the construction of the body is always desirable, so long as strength and reliability are not impaired thereby. If two bodies mounted on the sable model of chassis-have the same loading area and one is a cwt. heavier than the other, then the lighter vehicle has the advantage that, when fully loaded, it can carry a cwt. more of paying load than the other. The heavier vehicle is always carrying the extra cwt. as a dead and non-paying load. Light construction saves material and, from this point of view, is cheapet, but, on the other hand, the successful designing of a body having a minimum of weight is a task requiring much skill, the best workmanship and carefully selected materials.

It is a simple matter to add to the substance of a piece of framework, or to reinforce it with a steel plate so as to make sure that the structure wilI be strong enough, but it takes time and some financial outlay if experiments are to be made with more scientific forms of construction. However, in these days of rapid progress and keen competition, and the necessity for real economy, it is only right that every opportunity should be taken to eliminate all useless weight. Once the improved design is available, it can be applied all round and there is every chance that the extra expenditure incurred will be fully justified.

The weight of the unladen vehicle has been brought into prominence lately owing to the new scale of taxa

tion which came into force on January 1st last. Hitherto there had not been any great incentive to keep the unladen weight under one, two or three tons, as the case may be, because the extra tax payable on the next heavier class of vehicle in the schedule was of cdtnparatively small amount. In the table below the figures given show, not the actual amount of tax payable in each instance, but the amount saved by keeping the weight within a certain limit. For instance, if a vehicle weighed 22 cwt. unladen an extra £5 became payable because of the extra 2 cwt., but now a similar excess entails an additional annual expenditure of £10. The difference between the taxes on the 2-ton and 3-ton vehicle is now even more marked:— The effect at first of the new taxation will be to concentrate attention on the lighter class of vehicle. For some time past certain firms have been advertising the fact that their vehicles complete weigh under one ton. In the absence of special chassis being designed to upset the calculations of the Chancellor of the Exchequer, it follows that the body-builder is being called upon to make fresh designs, so that more favourable readings may take place at the weighbridge.

But the user, of course, cannot expect a new 2-tonner to do the work of an old 3-tonner, or to get over the difficulty by using a platform body if his class of trade demands a box-van, although it is possible that some users employ a heavier style of bodywork than is absolutely necessary. It is the elimination of the extra weight which will allow the vehicle to come just within the limit specified that is so desirable, but it will not always be possible.

Reduction of Headroom.

The simplest way of reducing the weight of the body is to decrease its overall dimenSions. But many users find that the body is often too small rather than too large, and it is only the fact that the ,vehicle is running light on many occasions, or is only partly loaded, which prevents the purchase of a larger or additional vehicle. Floor area is the vital factor, the tailboard forming a very useful means of increasing it ih emergencies. The depth of the ibody Ode of an open lorry is seldom in excess of daily requirements, and the only item which might be reduced with advantage is the headroom of a covered body.

The amount of headroom available is of particular importance when tall articles are carried,such as in the furnishing trades, or a large internal capacity is necessary when the load is light and bulky, as in the boxmaking trade. Head

room is not always required merely for pil ing up the load, but it facilitates working inside the van when loading or unloading, as well as enabling the goods to be readily inspected. Probably six inches could be taken off the headroom of many vans without decreasing the usefulness of the vehicle. Little weight would be saved, but there would be the advantage that this small economy would give the opportunity for increasing the rigidity of the superstructure.

Separate and Built-in Cabs.

It cannot be expected that weight can be saved by the radical alteration of any one feature of the body. The whole structure must be gone over detail by detail with the object of securing the desired result by the accumulation of many small improvements. It may be that only a few pounds is saved by cutting down the headroom, but there is the chance of saving a similar

amount by redesigning the driver's cab. The separate driver's cab is usually lighter than one which is included in the main structure of the body, because the former is more compact and has less headroom.

The built-in cab has a light superstructure, if the downward slope of the roof starts from the partition line or back of the seat rather than the front line of the seat, and the door line be well recessed, so that the windscreen may be kept within reasonable dimensions. The heaviest type of built-in cab is that fitted to the conventional box-van with a more or less straight roof line, which requires a large filler board above the windscreen. Enclosing the cab with full-length doors and sliding or drop windows entails additional weight, but comfort for the driver can also be obtained by the use of side curtains having celluloid lights.

A light pattern of the separate type of cab is also built by constructing the sides and roof with bent hoops and covering them with twill, to that the top is much after the style of the main portion of a sheet-van. The sides of the cab do not need to bea built strongly except to take the strain of the hanging of the doors and their constant shutting, unless a roof load is to be carried.

Eliminating Heavy Cross-bearers.

One of the easiest methods of saving weight is to mount the body as low down as possible on the chassis, for then the strength of the cross bottom bars or bearers need only be in proportion ta the weight to be carried when fully loaded, and no additional substance is required merely to give extra depth or to increase stability. In this way it should be possible in a large body to save as much as a 4 cwt. The low floor-line thus obtained results in labour being saved in loading and unloading, and more than compensates for the obstruction caused by the wheel-arches. Improved methods of mounting the body generally tend to give scope for lighter body construction.

If the driver's cab be built as a separate unit, it should not be 'bolted to the loading portion, but attached to the chassis only. A wide chassis helps the body designer to reduce the weight of the bottom frame, but it is doubtful if any advantage be gained when the weight of the complete vehicle is taken into consideration. Special mounting brackets or outriggers are useful in this respect, but weight can only be saved if these brackets weigh less than the extra amount of timber which would have to be used had they not been provided. Well-designed, light steel stxtnipings are indicated rather than forgings or castings.

The Weight of the Body.

Any discussion which deals with the weight of bodywork is rendered difficult because of the lack of figures giving the weights of representative types of body. Specifications differ widely and dimensions vary even for the same nominal load capacity. There is this advantage, however, that the question is not complicated by having to consider an extensive range of accessories and fittings as with private cars, which may or may not be included in the weight of the complete vehicle.

The weight of a goods body includes the driver's cab and windscreen, but not any dashboard provided with the chassis. In order to arrive at the average weight of the body, the set of wings and steps, with their respective stays, should be taken into account, although some or all of these may be included in the chassis specification. Approximate weights of representative types and sizes of commercial body are given in the following table:—

The user of a platform lorry, or of a Vehicle having a body with sides only, has the advantage that he can protect the load with a waterproof sheet, and this is not, as a rule, included in the weight of the body or complete vehicle. The value of the platform lorry is increased considerably (according to the class of goods carried) by the use of front and back boards, ridge poles and sometimes a partial or complete upper decking. Even with some or all of these items added, the weight of the body would not exceed that of the average sided lorry body, which is not so convenient for side loading, even when the sides are hinged.

The plank-sided body is cheaper to build and easier to repair than a body'having framed and panelled B29 sides. In some instances the use of slatted or skeleton sides would save a little weight, and this form can be adopted for the transport of livestock or when the goods are not likely to be spoilt by exposure to the weather. But the disadvantage of this style of construction is that the use of the lorry is restricted and it cannot transport material in bulk, such as sand or gravel. The tailboard can only be made up with openings if it is not to be used as an extension of the floor space.

Sheet-vans.

The sheet-van body is protected with a waterproof cover which may e detachable from its supporting hoops and longitudi Is, or be permanently fixed to this framework. It is a lighter form of construction than the boarded tilt, a d gives plenty of headroom, with a reasonable amoun of rigidity without undue weight.

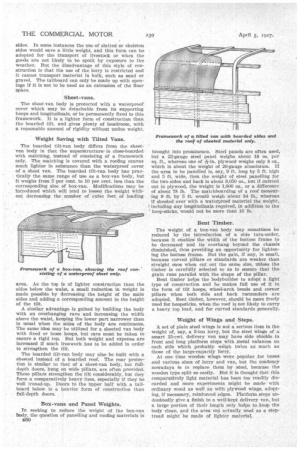

Weight s ing with Tilted Vans.

The boarded tilt an body differs from the sheetvan• body in that t e superstructure is close-boarded with matching, instead of consisting of a framework only. The matching is covered with a roofing canvas much lighter in substance than the waterproof cover of a sheet van. The boarded tilt-van body has practically the same range of use as a box-van body, but It weighs from 5 pei cent. to 10 per cent. less than the

corresponding size introduced which w out decreasing the

f box-van. Modifications may be 11 tend to lessen the weight withnumber of cubic feet of loading

area. As the top is of lighter construction than the sides below the watist, a small reduction in weight is made possible by decreasing the height of the main sides and adding a corresponding amount to the height of the tilt.

A similar advantage Is gained by building the body t

with an overhangi g rave and increasing the width above the waist, keilig the lower part narrower than is usual when the sides of the body are continuous. The same idea may he utilized for a sheeted van body with fixed or loose hoops, but care must be taken to ensure a rigid top. But both weight and expense are increased if much i onwork has tie be added in order to strengthen the tlilt.

The boarded tilt-tan body may also be built with a sheeted ittetead of a boarded roof. The rear protection is similar to that of a sheet-van body, but fulldepth doors, hung on wide pillars, are often provided. These pillars strengthen the tilt considerably, but they form a comparatively heavy item, especially if they be well ironed-up. IJopra to the upper half with a tailboard below is a 1eavier form of construction than full-depth doors.

Box-va s and Panel Weights.

In seeking to rqduce the weight of the box-van body, the question o panelling and roofing materials is brought into prominence. Steel panels are often used, but a 22-gauge steel panel weighs about 18 oz. per sq. ft., whereas one of plywood weighs only 8 oz., which is about the weight of 20-gauge aluminium. If the area to be panelled is, say, 9 ft. long by 5 ft. high and 5 ft. wide, then the weight of steel panelling for the two sides and back is about 3,050 oz., but if carried out in plywood, the weight is 1,800 oz., or a difference of about 78 lb. The matchboarding of a roof measuring 9 ft. by 5 ft. would weigh about 34 lb., whereas if sheeted over with a waterproof material the weight, including any longitudinals required, in addition to the hoop-sticks, would not be more than 10 lb.

Bent Timber.

The weight of a box-van body may sometimes be reduced by the introduction of a side turn-under, because it enables' the width of the bottom frame to be decreased and its overhang beyond the chassis diminished, thus providing an opportunity for lightening the bottom frame. But the gain, if any, is small, because curved pillars or standards are weaker than straight ones when cut out the same size, unless the timber is carefully selected so as to ensure that the grain runs parallel with the shape of the pillar.

Bent timber helps the bodybuilder to adopt a light type of construction and he makes full use of it in the form of tilt hoops, wheel-arch bends and corner pillars when both side and back turnunders are adopted. Bent timber, however, shpuld be more freely used for hoopsticks, when the roof is not likely to carry a heavy top load, and for curved standards generally.

Weight of Wings and Steps.

A set of plain steel wings is not a serious item in the weight of, say, a 5-ton lorry, but the steel wings of a smart 15-cwt. delivery van may have side shields in frcint and long platform steps with metal valances on each side Which probably weigh twice as much as those of the large-capacity lorry.

At one time wooden wings were popular for buses and various sizes of lorry and van, but the tendency nowadays is to replace them by steel, because the wooden type split so easily. But it is thought that this comparatively light material has been too readily discarded and more experiments might be made with ordinary wood as well as with plywood wings, adopting, if necessary, reinforced edges. Platform steps undoubtedly give a finish to a well-kept delivery van, but a large portion of their length only helps to keep the body clean, and the area not actually used as a steptread might be made of lighter material.