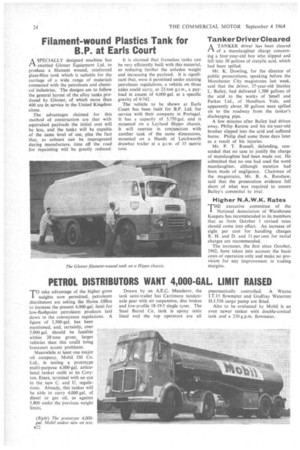

Filament-wound Plastics Tank for B.P. at Earls Court

Page 26

If you've noticed an error in this article please click here to report it so we can fix it.

ASPECIALLY designed machine has enabled Gloster Equipment Ltd. to produce a filament wound, reinforced glass-fibre tank which is suitable for the carriage of a wide range of materials connected with the petroleum and chemical industries. The designs are to follow the general layout of the alloy tanks produced by Gloster, of which more than 400 are in service in the United Kingdom alone.

The advantages claimed for this method of construction are that with equivalent payloads the initial cost will be less, and the tanks will be capable of the same level of use, plus the fact that, as colours can be impregnated during manufacture, time off the road for repainting will be greatly reduced. It is claimed that frameless tanks can be very efficiently built with this material, so reducing further the unladen weight and increasing the payload. It is significant that, were it permitted under existing petroleum regulations, a vehicle on three axles could carry, at 22-ton g.t.w., a payload in excess of 4,000 gal, at a specific gravity of 0.742. The vehicle to be shown at Earls Court has been built for B.P. Ltd. for service with their company in Portugal. It has a capacity of 3,750 gal. and is mounted on a Leyland Hippo chassis. It will operate in conjunction with another tank of the same dimensions, mounted on a Hands of Letchworth drawbar trailer at a g.t.w. of 35 metric tons.