Turbochargii yes Vivid Performance

Page 58

Page 59

Page 60

Page 63

Page 64

If you've noticed an error in this article please click here to report it so we can fix it.

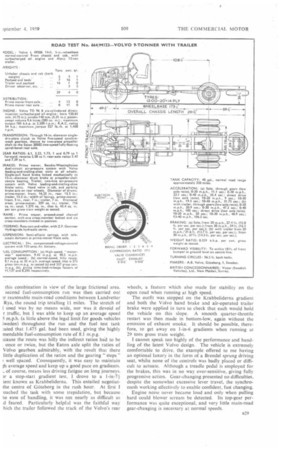

rscale Road Test of Turbocharged Heavy Shows Gains in Speed, Fuel Economy flew Performance : Outstanding Braking .es Achieved with 29-ton-gross Outfit

WHILST progress in Great Britain with turbocharged oil engines has been somewhat regrettably slow, the reverse has been the position in the rest of Europe, where there are many satisfactory designs in full production. One a the first vehicle manufacturers to experiment seriously with turbocharging was the Swedish company. A.B. Volvo, whose experience with turboblowers dates back to 1952 and who have been producing turbocharged engines at the rate of some 300 a year for the past four or five years. .

Opponents of turbocharging would do well to consider the success which the Swedish engineers have had with this method of raising the poWer output of a relatively small and light engine. The latest Volvo to be turbocharged sets an entirely new standard for heavy goods transport. For example, over a difficult undulating route at an average speed of 35 m.p.h. the fuel-consumption rate was 8.1 m.p.g. while running at a gross train weight of almost 291 tons, whilst at the same weight a speed of 30 m.p.h. was reached from a standstill in 47.2 seconds.

These figures were achieved with a 9.6-litre oil engine. the output of which (150 b.h.p.) is high even when normally aspirated. But with an Eberspacher turboblower (as produced in Great Britain by Simms Motor Units, Ltd.), the output is 185 b.h.p. at 2,200 r.p.m.. and the torque is 527 lb.-ft. at 1,400 r.p.m., an increase of 100 lb.-ft. over the yield from the normally aspirated version.

Another factor which would contribute towards the outstanding fuel economy and acceleration was the use of an Eaton 20502 two-speed axle, which unfortunately is not yet available in this country. This axle has a load rating of 101 tons and has a torque capacity quite sufficient to cope with an engine output of over 500 lb.-ft. driving through a gearbox bottom ratio of 6.1 to I.

If such an axle were available on the British market it would do much to speed up long-distance services without the need for greater power or complex trans

mission systems. It would be particularly suitable for high-speed articulated outfits working under motorway conditions, as the spread of axle ratios would make it possible for the tractive units to operate on normal British roads as well as on motorways.

The vehicle offered to me for test was a model from the new L495 range, which was introduced at the Geneva Show last March and went into production the following month. The L495 range succeeds the L395 models, an example of which has been road tested in this country (The Commercial Motor, November 16, 1956). The new range has been evolved as a result of operating experience gained in both Swedish and overseas markets with the L395 but there is still a large number of common parts between the new and old types of chassis.

One of the more important differences concerns the power unit, which has been modified in accordance with

experience gained with the original turbocharged version in order to give trouble-free service when turbocharged and improved overall longevity when normally aspirated. Engine modifications consist principally of the reduction of the risk of cylinder-head gasket failures; the use of reinforced pistons to increase strength and improve heat conductivity; the incorporation of chromium-plated upper piston rings and lead-bronze big-end bearings; a return to mechanical valve operation (the previous engine had hydraulic tappets), and the revision of fuel and lubricating oil filtration.

The normally aspirated engine is little changed when a turbocharger is applied, the principal differences being the use of modified inlet and exhaust manifolds and of a centrifugal fuel-pump governor instead of the vacuum governor employed on the standard unit. The fuel-pump elements are 9 mm. in diameter, compared with 8 mm. Two gearboxes are offered with the L495 range. Both are five-speed synchromesh units and one has an overdrive top gear of 0.79 to 1, with a bottom ratio of 6.1 to 1. This box is mandatory when the turbocharged engine is fitted, because the alternative gearbox, which has direct top drive and a bottom gear of 7.72 to I, would give too high a torque input into the rear axle when used with the turbocharged engine.

The standard rear axle is an Eaton two-speed axle There are two available sets of ratios: 8.36 and 6.14 to 1 and 7,39 and 5.43 to 1 (as tested). the Eaton axle has spiralbevel gearing and an electrical shift mechanism.

The standard chassis frame has 9i-in.-deep side members pressed from 11,-in.-thick material and there are four

alligator-type riveted cross-members. Reinforced strips are riveted to the upper and lower flanges of the side members, and for extra-heavy-duty application L-shaped flitch plates can be provided on the outside of the main members.

Spring Length Increased Longer front springs are employed in the L495, compared with the L395, the current chassis having 54-in. springs, an increase of 9 in. The rear springs are 59 in. long and work in conjunction with 40-in. helper leaves, and large telescopic dampers. are standard equipment at the front. Ross cam and twin lever steering gear is standard, and ZF-Gemmer Hydraguide power gear, which has its power pistons integral with the steering box, can be supplied.

A change concerns the braking system, a BendixWestinghouse split-circuit layout being employed. This is fed by a water-cooled compressor and the maximum working pressure is 105 p.s.i. A transmission drum-type hand brake is retained, and a tractor protection valve can be incorporated.

In deference to demands from certain Volvo export areas. Trilex spoked wheels can be fitted and were employed on the test vehicle, which had 12.00-20-in. tyres. Trilex wheels can also be used when 10.00-20-in. and 11.00-20-in. tyres are specified, the standard equipment for these sizes being 7.5-20-in, disc wheels.

There are five chassis in the new range. All are rated for a gross solo weight of 15 tons and the wheelbases are 12 ft. 6 in., 14 ft. 5 in. (as rested), 15 ft. 9 in., 17 ft. 1 in. and 18 ft. 5 in. All chassis are recommended as suitable for a gross train weight of 32 tons, although in service higher operating weights have been reported without noticeable loss of performance.

Over Legal Limit

The kerb weight of the chassis and cab tested was 5 ton 3+ cwt, and a test platform body loaded with iron weights had been mounted on it, so that the gross solo weight, with myself and Volvo driver aboard, came to 12 tons 194 cwt. —slightly over the maximum permissible weight at which a solo four-wheeler is allowed to operate in Sweden.

An Alpus four-wheeled drawbar trailer carrying 12 tons of iron weights was hauled, its total weight being 16 tons 1 cwt. Alpus trailers are made by a concern in Goteborg to whom Volvo supply certain components. The trailer tested, which had twin tyres all round, was fitted with similar braking equipment to that on the rear axle of the L49 chassis, and the high frictional area of the complete outfit produced some remarkable braking results.

Braking tests, both with and without the trailer, were carried out on a level, little-used stretch of road running parallel with the Goteborg-Kungalv motorway. As recorded in the data panel, stopping distances when running solo were highly satisfactory from both 20 m.p.h. and 30 m.p.h., but even more remarkable figures were achieved with the trailer. The stopping distances were only 4.2 ft.

a26 greater from 20 m.p.h. and 8 ft. longer from 30 m.p.h. than on solo work.

These results tend to destroy the fallacy that a vehicle with a drawbar trailer is potentially more dangerous than a rigid outfit of the same capacity. If a trailer is adequately braked (as the Alpus undoubtedly was), and assuming correct balance between the air-pressure systems of it and the towing vehicle, the addition of a trailer need make little difference to the potential retardation of the solo outfit.

When braking from 20 m.p.h., the rear wheels of the Volvo and the trailer locked, the average maximum retardation indicated by the Tapley meter being 68.5 per cent. When braking from 30 m.p.h. the same wheels locked and the maximum retardation was 66 per cent. From both speeds the outfit came to rest virtually in a straight line.

A hand-brake application from 20 m.p.h. when running solo produced a Tapley meter reading of 70 per cent., which is only to b‘e expected in view of the use of a transmission drum. This test was made only once, because even light application of the lever caused the rear wheels to lock immediately and the back axle to hop somewhat alarmingly.

All the acceleration tests were conducted with the rear axle in its low ratio, those made from a standstill up to 40 m.p.h. demanding the use of second, third and fourth gears only (the maximum speed in fourth is 41 m.p.h.). Fourth gear and low axle ratio were employed for the direct-drive tests (top gear is an overdrive). I was particularly impressed with the way in which the engine pulled away smoothly from 10 m.p.h. and the immediate response of the turbocharger to full throttle opening, there being no appreciable evidence of delay in the build-up of the blower effect.

Fantastic Time-load-mileage Factor

While in the area I decided that it would be interesting to make a fuel-consumption test on the motorway under high-speed conditions. The vehicle was driven over a threemile stretch at a maximum speed of about 45 m.p.h. and the somewhat surprising fuel return of 9.42 m.p.g. gave a timeload-mileage factor of 11,137. This is by far the highest figure ever achieved during a test by The Commercial Motor and is unlikely to be beaten for many years to come by a standard production vehicle of thrs type.

This result indicates the advantages that could be derived from the use of a high-geared vehicle with a turbocharged oil engine on the future British motorways in affording a high average speed and low fuel costs. The turbocharger would provide the extra power needed and compensate for the higher gearing when the vehicle had to be driven over normal British roads in and out of towns at each end of the motorway.

From the Kungiilv area the outfit was driven out to Partille, where there is a l4-mile climb averaging 1 in 20, The road surface is unsealed and consequently is very dusty in the hot, dry weather in which the test was made. Ambient temperature was 66F. and the radiator coolant was 152'F. before making the climb.

The ascent lasted only seven minutes, the Volvo careering up the hill, looking and sounding like a wheeled rocket missile. The minimum speed was 12 m.p.h. and the lowest ratio employed—second-low—was needed for only two minutes, most of the climb being made in second-high and third-low. The ascent caused a temperature rise of only 27F., which is particularly good in view of the tow engine speed throughout most of the climb. At no time during this or any other test was T able to see any exhaust smoke.

Because of the somewhat loose road surface and the size and weight of the vehicle. I did not attempt a brakefade test, but there should be little fear of fade occurring this combination in view of the large frictional area. second fuel-consumption run was then carried out nreasonable main-road conditions between Landvetter Rya, the round trip totalling 11 miles. The stretch of I used was by no means wide, nor was it devoid of r traffic, but I was able to keep up an average speed 5 m.p.h. (a little above the legal limit for goods vehicles iweden) throughout the run and the fuel test tank ated that 1.475 gal. had been used, giving the highly mendable fuel-consumption rate of 8.1 m.p.g. : xause the route was hilly the indirect ratios had to be once or twice, but the Eaton axle split the ratios of VOlvo gearbox admirably, with -the result that there little duplication of the ratios and the gearing " steps" : well spaced. Consequently, it was easy to maintain at average speed and keep up a good pace on gradients. , of course, means less driving fatigue on long journeys. )r a stop-start gradient test, I drove to a 1-in-71 lent known as Krabbeliderna. This entailed negotiatthe centre of Goteborg in the rush hour. At first 1 pached the task with some trepidation, but because he ease of handling, it was not nearly as difficult as d feared. Particularly helpful was the faithful way hich the trailer followed the track of the Volvo's rear

wheels, a feature which also made for stability on the open road when running at high speed.

The outfit was stopped on the Krabbeliderna gradient and both the Volvo hand brake and air-operated trailer brake were applied in turn to check that each would hold the vehicle on this slope. A smooth quarter-throttle restart was then made in bottom-low, again without the emission of exhaust smoke. It should be possible, therefore, to get away on l-in-6 gradients when running at 29 tons gross train weight.

I cannot speak too highly of the performance and handling of the latest Volvo design. The vehicle is extremely comfortable to drive, the example offered to me having an optional 'luxury in the form of a Brendel sprung driving seat, whilst none of the controls was badly placed or difficult to actuate. Although a treadle pedal is employed for the brakes, this was in no way over-sensitive, giving fully progressive action. Gear-changing presented no difficulties, despite the somewhat excessive lever travel, the synchromesh working effectively to enable confident, fast changing.

Engine noise never became loud and only when pulling hard could blower scream be detected. Its top-gear performance was quite exceptional, and very little main-road gear-chaaging is necessary at normal speeds. Driving vision was found to be generally good, particularly to the rear, the wide rear window in the .Nystrom cab being supplemented by two large, rigidly supported driving mirrors on top of which were mounted the forward flashing direction indicators. The cab is excellently equipped, even to the extent of automatic interior lights, and there is ample space alongside the driver to seat two. passengers in comfort.

The basic price of the normally aspirated L495 chassis is just over £3,000 in Sweden and the turbocharger adds £205 to this figure. Including all the extras, the vehicle as tested costs just under £4,000. Turbocharger life, as estimated by the Volvo engineers, is in the region of 65,000 miles between replacements, ailhough this figure has been exceeded appreciably in service, and replacement blowers can be supplied. This alone indicates the progress that had been made by A.B. Volvo in the field of turbocharging. for when first reported on the Volvo turbocharged engine nearly five years ago, the recommended life between blower replacements was only 30,000 miles.

The reliance that Volvo are placing on their turbocharged engines is, I feel, fuIly justified. Operators are reporting reduced overall operating costs, the general opinion being that fuel economy is increased if higher maximum speeds are not employed. Alternatively, with suitable gearing, maximum trip speeds can be raised without detriment to the fuel consumption. Either way, the extra charge incurred by the provision of the turboblower is quickly recovered and no serious faults have occurred in service over the past five years. A further advantage is that because of its turbo. charger this 185 b.h.p. unit is little bulkier and heavier than a conventional 125 b.h.p oil engine.