Another Paraffin Vaporizer.

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

Particulars of .a Gas Producer of Recent American Manufacture.

A paraffin carburetter, independent of any auxiliary fuel system for starting-up purposes, and one which would be a success commercially, is one of the pressing requirements of every automobile engineer. From time to time there is an attempt made to produce some form or another of satisfactory • paraffin vaporizer ; many paraffin carburetters -come and go but, with a very few interesting exceptions, no exact approach to "the survival of the attest " has yet been recorded. The present significant nature of the problem of liquid fuel serves, of course, to uive impetus to inventors and -manufacturers in this respect, both at home and abroad.

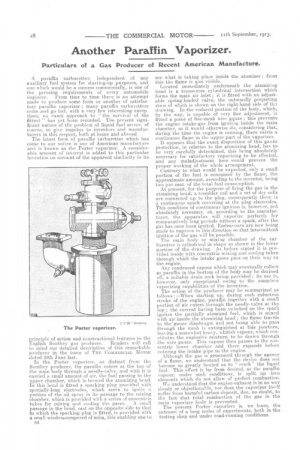

The latest form of paraffin carburetter which has come to our notice is one of American manufacture and is known as the Porter vaporizer. A considerable amount of interest is added to this particular invention on account of the apparent similarity in its principle of action and constructional features to the English Southey gas producer. Readers will call to mind our detailed description of this remarkable producer in the issue of THE COMMERCIAL Mown dated 20th June last.

In the Porter vaporizer, as distinct from the Southey producer, the paraffin enters at the top of the main body through a needle-valve, and with it is -carried a small amount of air,' the fuel passing to the upper chamber, which is termed the atomizing head. In this head is fitted a sparking plug provided with specially-long, electrodes, which serve to ignite a portion of the oil spray in its passage to the mixing chamber, which is provided with a series ef concentric tubes for mixing and cooling the gases. A small passage in the head, east on the opposite side to that in which the sparking plug is fitted, is provided with a small windoweomposed of mica, this enabling one to 134 see what is taking place inside the atomizer ; from this the flame is also visible.

Located immediately underneath the atomizing head is a transverse cylindrical intersection which forms the main air inlet ; it is fitted with an adjustable spring-loaded valve, the outwardly projecting stem of which is shown on the right-hand side of the drawing. In the reduced portion of the body, which, by the way, is capable of very fine adjustment, is fitted a piece of fine-mesh wire gauze ; this. prevents the engine intake-gas from igniting inside the main chamber, as it would otherwise do, considering that, during the time the engine is running, there exists a continuous flame in the upper part of the vaporizer.

It appears that the exact disposition of this gauze protection, in relation to the atomizing head, has to be very carefully determined, this being absolutely necessary for satisfactory vaporizing to be effected, and any maladjustment here would prevent the proper working of the whole arrangement.

Contrary to what would be expected, only a small portion of the fuel is consumed by the flame, the approximate a-mount, according to the inventor, being two per cent. of the total fuel consumption.

At present, for the purpose of firing the gas in the atomizing head, a, trembler coil and a set of dry cells are connected up to the plug, consequently there is a continuous spark occurring at the plug electrodes. This condition of continuous ignition is, however, not absolutely necessary, as, according to the manufacturer, the apparatus will vaporize perfectly fer comparatively long periods without a spark, after the gas ha-s once been ignited. Endeavours. are now being made to improve in this direction so that intermittent ignition of the gas will be possible.

The main body or mixing chamber of the carburetter is cylindrical in shape as shown in the lower portion of the drawing. As before stated it is provided inside with concentric mixing and cooling tubes: through which the intake gases pass on their way to the engine. Any condensed vapour which may eventually collect as paraffin in time bottom of the body may be drained off, a, suitable drain -cock being provided ; its use is, however, only exceptional owing to the complete vaporizing capabilities of the invention.

The action of the producer may be summarized as follows :—When starting up, during each induction stroke of the engine, paraffin together with a small portion of air enters through the needle-valve at the top ; the current having been switched on the spark ignites the partially atomized fuel, which is mixed with air inside the atomizing head ; the flame travels to thegauze diaphragm and not being able to pass through the mesh is extinguished at this juncture, leaving a somewhat heavy, whitish vapour, which constitutes the explosive mixture, to be drawn through the wire gauze. This vapour then passes to the concentric lower chamber and there expands before entering the intake'pipe to the engine. Although the gas is generated through the agency of a flame, we understand that the device does not become so .greatly heated as to " crack" the liquid fuel. This effect is far from desired, as the paraffin vapour, under such conditions, is split up into elements which do not allow of perfect combustion.

We understand that. the engine-exhaust is in no way cloudy or objectionable, nor does the vaporizer itself suffer from harmful carbon deposit, due, no. doubt, to the fact that total combustion of the gas in the main vaporizer body is prevented. The present Porter vaporizer is, we learn, the outcome of a long series of experiments, both in the testing shop and under road-running conditions.