Two of a kind

Page 25

Page 27

Page 28

Page 29

Page 30

If you've noticed an error in this article please click here to report it so we can fix it.

In the first of a new series pitting vehicles head-to-head, CM puts two of CJ Bird’s 18-tonners up against each other

Words: Bob Beech / Images: Tom Cunningham While many operators regard 18-tonne rigids as primarily distribution vehicles, used mainly for shortto medium-distance operations, not many know that they can be specified for far more diverse operations. CJ Bird Transport, based in south Wales, is one operator that uses its rigid fleet for a combination of UK distribution, UK/European express operations and specialist transport for exhibition, conferences and events. The specifications for the Mercedes-Benz and Daf featured here have been tailored to suit these applications and highlight the flexibility of both manufacturers’ product ranges.

Operator Opinion: Chris Bird, MD C J Bird

“We run an assortment of rigids and artics, from 7.5 tonnes to three-axle 26-tonners. Quite a number are two-axle 18-tonners used on a variety of work, including longdistance international operations. Most of the makes we have tried perform well and give little trouble. We look for at least 800,000km from a rigid in front-line service, and then maybe another 200,000km more on local operations. Some might question this, but we have a number of older trucks still giving reliable service every day.

“I think many operators change their trucks far too early. Obviously, trucks on lease contracts are returned at the end of the term, but we prefer to buy the truck outright and then keep it for its full working life. This allows us to derive the full value from the vehicle rather than handing it over to another user when it still has a lot of life left in it. This is especially important with trucks that have bespoke bodywork and other equipment as part of their specification.

“The key to a long and cost-effective life is obviously to buy the right truck, taking real care with total specification. Then you have to maintain it in the most effective way throughout its life. In the past we took out R&M contracts with the appropriate dealer when purchasing new trucks, but our experience has shown this to be less than satisfactory in the long term. Now we use a local independent garage that provides us with a first-class service. The overall cost is similar, but the quality of the workmanship and convenience is far greater.

“We have yet to find a franchised dealer that can provide us with this, regardless of the make of truck they sell. The problems include poor levels of response, lack of parts availability and, most importantly, failure to rectify reported defects when required. I realise that all dealers are under financial pressure, but if a small contractor with relatively modest premises can meet our requirements, then why can’t they do the same?

“The cornerstone of our own business is the high level of reliable service we offer our customers. They are not interested in excuses if we fail to deliver, regardless of whose fault it might be. All we ask is that a truck dealer works to a similar standard.

“We have used Mercedes-Benz rigids for many years. I started over 20 years ago with an 814 7.5-tonner and have always liked the product. We run quite a number of Axor/ Atego rigids and they generally perform reliably and are quite popular with the drivers. The 1824 featured here went into service last year and has given few problems so far. “We specified the longest possible wheelbase, an automated gearbox, rear air suspension, an 8-tonne front axle and the biggest cab with a reasonably high level of equipment. The one area that lets the truck down is the engine output. The relatively high gearing means that the 240hp engine struggles a little on motorway hills, with just six gears it really needs a bit more power. We would have had the optional 290hp engine, but it’s only available with the manual transmission.

“Dissatisfaction with Volvo a while back pushed us towards Daf. We had persistent fuel consumption problems with FM9 rigids, combined with aftermarket issues, leading us to look elsewhere.

“The Daf product range is flexible – it’s possible to upgrade the specification on a CF65 18-tonner at a reasonable cost. We went for the 300hp engine, with the six-speed AS Tronic and the high roof Space Cab. It has the same chassis layout as the Axor and carries a similar box body, although this particular truck is generally used on international exhibition work, where the driver can be away for as many as three weeks at a time.

“The extra power overcomes the effect of the six-speed auto and the truck performs well. The cab offers first rate accommodation. Other features such as the factory-fitted blind spot camera are excellent and show that Daf really does try to understand operators’ requirements. Furthermore, Daf’s breakdown service in both the UK and Europe is by far the best.

“Overall, I probably rate the Daf as the better buy. It has better performance, a slightly better cab and replacement parts are not too expensive, which is an important factor as a truck ages.”

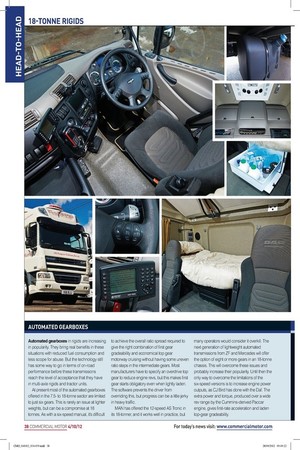

AUTOMATED GEARBOXES

Automated gearboxes in rigids are increasing in popularity. They bring real benefits in these situations with reduced fuel consumption and less scope for abuse. But the technology still has some way to go in terms of on-road performance before these transmissions reach the level of acceptance that they have in multi-axle rigids and tractor units.

At present most of the automated gearboxes offered in the 7.5to 18-tonne sector are limited to just six gears. This is rarely an issue at lighter weights, but can be a compromise at 18 tonnes. As with a six-speed manual, it’s difficult to achieve the overall ratio spread required to give the right combination of first gear gradeability and economical top gear motorway cruising without having some uneven ratio steps in the intermediate gears. Most manufacturers have to specify an overdrive top gear to reduce engine revs, but this makes first gear starts obligatory even when lightly laden. The software prevents the driver from overriding this, but progress can be a little jerky in heavy traffic.

MAN has offered the 12-speed AS Tronic in its 18-tonner, and it works well in practice, but many operators would consider it overkill. The next generation of lightweight automated transmissions from ZF and Mercedes will offer the option of eight or more gears in an 18-tonne chassis. This will overcome these issues and probably increase their popularity. Until then the only way to overcome the limitations of the six-speed versions is to increase engine power outputs, as CJ Bird has done with the Daf. The extra power and torque, produced over a wide rev range by the Cummins-derived Paccar engine, gives first-rate acceleration and laden top-gear gradeability.

MAINTENANCE OPTIONS

In recent years, many hard-pressed operators have turned to contract maintenance to control costs. The increasing complexity of modern vehicles, along with the relatively high costs of operating your own workshop, has led to rapid growth in this sector, and most operators seem reasonably pleased with the result.

But for some all is not as it should be. This operator, along with others we have spoken to recently, is less than happy with the standard of service they have received from main dealer workshops. Complaints include poor workmanship, failure to rectify vehicle defects while carrying out a service, a lack of communication, the time and expense of taking vehicles to dealers premises and an overall lack of care shown by some workshop staff.

During our interview, Bird made two interesting observations. First, he feels that any LGV maintenance contractor should hold some form of licence and be subject to appropriate action from the authorities if they fail to carry out their duties to the required standard – a valid point considering any negligence could well lead to the vehicle owner losing his operator’s licence.

Second, with modern trucks often having a capital cost of £100,000 or more, is it too much to ask that workshop staff do their best to return the vehicle in the same condition it was in when it arrived at their premises?

In some instances this might well be filthy with numerous knocks and scrapes, but many operators and their drivers take great pride in their vehicles and expect others to act accordingly. It does wonders for customer relations and might well encourage them to come back in the future.

Engine ratings apart, both these trucks are well matched and have been in production for many years. The Mercedes will be replaced at Euro-6 by the new Antos range, and we imagine that any shortcomings of the current Axor will be dealt with effectively by the new model. But the Axor will still be available for a while, and many of the existing trucks will continue in service for many years to come.

Daf has yet to announce its plans for the CF range at Euro-6, but the chances are that the Dutch manufacturer will limit changes to only what is necessary.

This policy has stood the company in good stead for the last decade or more, and it certainly hasn’t affected its sales performance throughout Europe.

As this operator has found, it’s possible to tailor each of these trucks to meet specific requirements (which demonstrates the flexibility of both manufacturers).

The Axor’s weak point in this instance is the lack of a more powerful engine with the automated gearbox. The benefits of two-pedal transmissions are difficult to appreciate if the truck struggles on the hills, as many drivers lose patience and use the manual mode. As it stands, the truck needs either more power and torque with a sixspeed gearbox, or two more intermediate ratios.

The CF65 in this form is an impressive machine. It might be a bit overpowered for some bigger fleets, but in this operation it’s difficult to fault. It has lots of driver appeal and is a pleasure to drive. Possibly its only weakness is the lack of a higher capacity front axle as 7.5 tonnes is a bit marginal for a high-power truck with a big cab, if used for multidrop operations, otherwise the Daf gets our vote.

Fuel consumption

Mercedes-Benz Axor 1824: 13.15mpg average over 58,000 miles/long-distance UK operation Daf CF65.300: 13.3mpg average over 79,000 miles/predominately long-distance European operation AdBlue consumption: Both average 20 to 25 litres per week