Sheppard side-loader to handle ISO freight containers

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

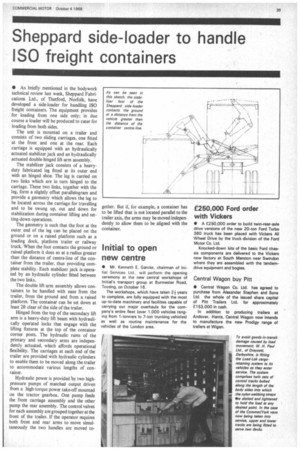

• As briefly mentioned in the bodywork technical review last week, Sheppard Fabrications Ltd., of Thetford, Norfolk, have developed a side-loader for handling ISO freight containers. The equipment provides for loading from one side only; in due course a loader will be produced to cater for loading from both sides.

The unit is mounted on a trailer and consists of two sliding carriages, one fitted at the front and one at the rear. Each carriage is equipped with an hydraulically actuated stabilizer jack and an hydraulically actuated double-hinged lift-arm assembly.

The stabilizer jack consists of a heavyduty fabricated leg fitted at its outer end with an hinged shoe. The leg is carried on two links which are in turn hinged to the carriage. These two links, together with the leg, form a slightly offset parallelogram and provide a geometry which allows the leg to be located across the carriage for travelling and to be swung up, out and down for stabilization during container lifting and setting-down operations.

The geometry is such that the foot at the outer end of the leg can be placed on the ground or on a raised platform such as a Loading dock, platform trailer or railway truck. When the foot contacts the ground or raised platform it does so at a radius greater than the distance of centre-line of the container from the trailer. thus providing complete stability. Each stabilizer jack is operated by an hydraulic cylinder fitted between the two links.

The double lift-arm assembly allows containers to be handled with ease from the trailer, from the ground and from a raised platform. The container can be set down at least 2ft clear of the side of the trailer.

Hinged from the top of the secondary lift arm is a heavy-duty lift beam with hydraulically operated locks that engage with the lifting fixtures at the top of the container corner posts. The hydraulic rams of the primary and secondary arms are independently actuated, which affords operational flexibility. The carriages at each end of the trailer are provided with hydraulic cylinders to enable them to be moved along the trailer to accommodate various lengths of container.

Hydraulic power is provided by two highpressure pumps of matched output driven from a high-torque power take-off mounted on the tractor gearbox. One pump feeds the front carriage assembly and the other pump the rear assembly. The control valves for each assembly are grouped together at the front of the trailer. If the operator requires both front and rear arms to move simultaneously the two handles are moved to

gether. But if, for example, a container has to be lifted that is not located parallel to the trailer axis, the arms may be moved independently to allow them to be aligned with the container.

Initial to open new centre

• Mr. Kenneth E. Garcke, chairman of Initial Services Ltd., will perform the opening ceremony at the new central workshops of Initial's transport group at Burmester Road, Tooting, on October 16.

The workshops, which have taken 2+ years to complete, are fully equipped with the most up-to-date machinery and facilities capable of carrying out major overhauls for the company's entire fleet lover 1,000 vehicles ranging from 1-tonners to 7-ton trunking vehicles) as well as routine maintenance for the vehicles of the London area.

£250,000 Ford order with Vickers

• A £250,000 order to build twin-rear-axle drive versions of the new 20-ton Ford Turbo 360 truck has been placed with Vickers All Wheel Drive by the truck division of the Ford Motor Co. Ltd.

Knocked-down kits of the basic Ford chassis components are delivered to the Vickers new factory at South Marston near Swindon where they are assembled with the tandemdrive equipment and bogies.

Central Wagon buy Pitt • Central Wagon Co. Ltd. has agreed to purchase from Alexander Stephen and Sons Ltd. the whole of the issued share capital of Pitt Trailers Ltd. for approximately £153,000 in cash.

In addition to producing trailers at Andover, Hants, Central Wagon now intends to manufacture the new Prodigy range of trailers at Wigan.