A CHASSIS BUILT OF WELDED SHEET METAL.

Page 46

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

Details of a Remarkable and Practicable New British Product Built Under the Fejes Patents.

SOME 18 months ago we dealt in this journal with an unusual chassis of Czecho-Slovakian origin in which most of the parts. including the major units, were constructed of sheet-steel, either plain, or pressed and welded.

Many chassis built in this manner have been running for some time in the service of the Czecho-Slovakian Army and Post Office, and they are giving excellent results under arduous conditions of. service.

The system of manufacture is by no means confined to the lighter models, for some of those in use are built to carry leads of several tons.

In our own country little has been heard here of the Fejes until recently, bat it has by no means been neglected, and the Fejes Patents Syndicate, Ltd., 25, Victoria Street, London, S.W.1, has actually produced several chassis of allBritish construction built under the Fejes patents. These chassis are being subjected to arduous tests, and real production for the market will not occur before approximately a year has elapsed. The chassis so far built are intended to carry private-car bodies, although, as a matter of fact, they would certainly make excellent little vans, and we publish a composite photograph showing an Ascot, as the vehicle is known, as a light van.

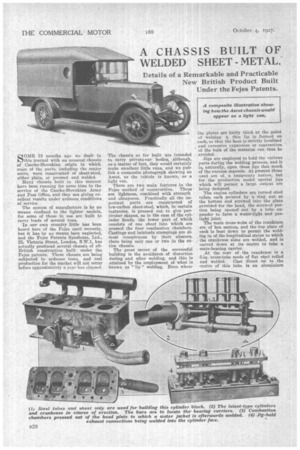

There are two main features in the Fejes -method of construction. These' are lightness, combined with strength and cheapness. Practically all the important parts are constructed of low-carbon sheet-steel, which, in ' certain instances, is pressed out to give particular shapes, as in the case of the cylinder heads, the lower part of which consists of one sheet into which are pressed the four combustion chambers. Castings and intricate stampings are almost conspicuous by their absence, there being only one or two in the entire chassis.

The great secret of the successful building is the avoidance of distortion during and after -welding, and this is attained by the employment of what is known as " lip " welding. Even where

the plates are fairly thick at the point of welding a thin lip is formed on each, so that the heat is strictly localized and excessive expansion or contraction of the hulk of the material can thus be avoided.

Jigs are employed to hold the various parts during the welding process, and it is, naturally, upon these jigs that much of the success depends. At present those used are of, a temporary nature, but for the production model special jigs which will permit a large output are being designed.

• The engine cylinders are turned steel tubes, each secured by a ring nut at the bottom and screwed into the plate provided for the head, the screwed portion being opened out by a tube expander to form a water-tight and gastight joint..

The main cross-webs of the crankcase are of box section, and the top plate of each is bent down to permit the welding in of the longitudinal strips to which the crankcase sides are welded, and is curved down at its centre to take a main-bearing carrier.

At the rear of the crankcase is a 5-in, cross-tube made of flat steel rolled and welded. Cast direct on to the centre of this tube is an aluminium

casing carrying the timing mechanism, which includes one pair of skew, gears and one pair of bevel gears, the latter driving the distributor and dynamo, which are accommodated in the projecting portions of the tube; these being cut away at the top to give good accessibility, and accommodated in frarno saddle-plate brackets having rubber bushes. The front end of the crankcase is supported on a plate bent to give a certain amount of spring or PlialPing action, and this, being bolted to the crankcase at its centre only forms, in effect, a third point of susPensicm.

Even the engineers at first thought that the building-up of an engine anti

method of construction is the smooth interior of the combustion chambers. This has been found to permit a compression ratio of 61, to 1 without causing pinking on hills or when running at low speed on top gear, whilst the unrestricted passages for the gases make the engine efficient even at high speeds.

The crankshaft is, of course, of normal design. It is carried in three large main hearings with removable caps, and there is a single camshaft, also of normal design, operating the side-byside valves which, in the production model, will be enclosed. The bearing

carriers and the housings for the camshaft bashes are, of course, bored out after the completion of the welding, sothat they are absolutely true. "Similarly, a small allowance is permitted in the cylinders to enable the to be trued after welding. In practice, it has been found that even with temporary jigs the error on a whole cylinder -block does not exceed 1-32 in.

Lubrication is effected under pressure, the oil being circulated by an oscillating-plunger pump driven from the end of the camshaft. Oil is fed to the main and camshaft bearings, the big-end bearings receiVing their supply from :the main hearings through the hollow crankShaft.

Ignition is effected by a coil anti distributor, and carburation by a horizontal Zenith instrument bolted direct to the cylinders.

Thermo-siphonic circulation is employed for the cooling water, and there is a fan, but experience has shown that the use of this is only essential when the temperature is considerably above normal, as the thinness of the water jackets and crankcase make the engine act partly as its own radiator.

The drive is taken through a singleplate dry clutch with circular inserts of asbestos-fabric material to a three

speed-and-reverse gearbox with central Change, flexible disc joints being utilized on the clutch shaft.'" The gearbox is also constructed of steel plates and pressings welded together. It is spigoted into a stout boxsection cross-member, which also serves as the anchorage for the spherical end of the torque tube, within which is a metal universal joint.

The rear axle is-of normal type,. with welded pressed-steel casing, but the brake carriers are of special design, having pressed-steel plates and tubes welded together. .

Internal-expanding brakes operate on all four wheels and the front axle is of the. ordinary Ackerman type. Likewise, long and flexible . semi-elliptic springs are employed all round.

Particular interest attaches to the frame. The side members consist . of four steel plates welded together and joined by box-section cross-members, each built of four plates. If a dumbiron be bent or crushed through an accident, it is only necessary to file away the weld at the lips, straighten the individual plates, and reweld.

To avoid indiscriminate drilling of the frame by eoachbuilders, a series of Cubes or ferrules is welded into the side members, and through these suitable bolts can .be passed.

Chassis lubrication is on the greasegun system.

In the production model all levers,

pedals, etc., will be -of welded pressed steel.

The tags dimensions are as follow: Wheelbase, 9 ft.; track, 4 ft., 2 ins.; ground clearance, 8 ins.; turning circle, 44 ft.

The .engine is rated at 10 h-p. It has four cylinders of 03 mm. bore and 110 ram, stroke, giving a capacity of 1,371 c.c.

As a four-seater car, complete with hood and side curtains, the Ascot weighs some 15 cwt. only, thus saving approximately 3 cwt. over a corresponding car built in a normal manner. It is designed to run at a maximum speed of 40 m.p.h., although tests have shown it capable of exceeding this speed by a considerable amount, and we are informed that in a test run from London to Glasgow and back the average mileage per gallon proved to be 51.

We took over the wheel for some miles, and found the vehicle was simple to handle, remarkably powerful for its size of engine, and with a good acceleration. There is one thing that we noted particularly when driving this vehicle—that was the complete absence of drumming.

As a -complete four-seater touring ear the price will be about £125.