A New Omnibus Engine.

Page 4

Page 5

If you've noticed an error in this article please click here to report it so we can fix it.

The Product of the Parisian Firm oi Bariquand and Marre.

The British Bariquand and Marre Engine Company, Limited, a subsidiary company of the parent one in Paris, has recently acquired commodious premises and show rooms at to, Poland Street, Oxford Street, W. ; although the registered offices are still at 18, Leadenhall Street, E.G. The company is making the sale of motor omnibus engines a special branch of its business, and it is for this reason that the new premises have been obtained. A large stock of engines and spare parts is kept, so that no unnecessary delay need be experienced by purchasers. The factory in Paris is an old-established one; it produces many different classes of machinery, and, also, a large number of Maxim-Nordenfelt machine guns have been constructed there. All parts of engines belonging to the different types are absolutely standardised, and new spare parts can always be relied upon to fit in their respective places, and, further, all engines carry with them a guarantee, for three years, against defective workmanship or material.

At present, three classes of engines are made for commercial vehicles : a tah.p. four-cylinder one, which has a bore of 9ornm. and a piston stroke of izomm., to he used in light work, such as delivery vans and so on ; a 24-3oh.p. engine for general lorry and omnibus work: and a 35-40h.p.

engine for the same purpose, but particularly suited to hilly districts or where the service conditions are unusually severe.

A low fuel consumption is claimed for the above engines, owing to the use of a patented carburetter of the company's own design : one of the 24-3oh.p. engines has run considerably over ten miles, upon one gallon of petrol, in a bus.

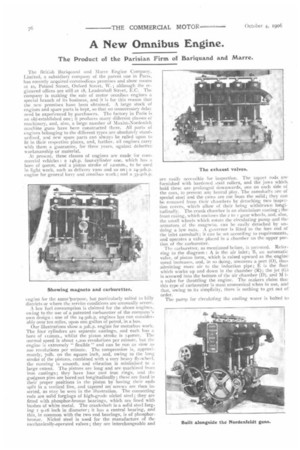

Our illustrations show a 3oh.p. engine for motorbus work. The four cylinders are separate castings, and each has a bore of i tznun., whilst the piston stroke is t4omni. The normal speed is about 1,m) revolutions per minute, but the engine is extremely " flexible " and can be run as slow as zoo revolutions per minute. The compression is, approximately, 7o1b. on the square inch, and, owing to the long stroke of the pistons, combined with a very heavy fly-wheel, the running is smooth, and vibration is minimised to a large extent. The pistons are long and are machined from iron castings ; they have four cast iron rings, and the gudgeon pins are bored out longitudinally; these are fixed in their proper positions in the piston by having their ends split in a vertical line, and tapered set screws are then inserted, as may be seen in the illustration. The connecting rods are solid forgings of high-grade nickel steel; they are fitted with phosphor-bronze bearings, which are lined with hushes of white metal. The crankshaft is a solid steel forging I 9-16 inch in diameter; it has a central bearing, and this, in common with the two end bearings, is of phosphorbronze. Nickel steel is used for the manufacture of the mechanically-operated valves ; they are interchangeable and are easily accessible for inspection. The Lappet rods are furnished with hardened steel rollers, and the jaws which. hold these are prolonged downwards, one on each side of the cant, to prevent any lateral play. The camshafts are of special steel and the cams are cut from the solid; they can be removed from their chambers by detaching two inspection covers, which allow of their being withdrawn longitudinaliy. The crank chamber is an aluminium casting; the front casing, which encloses the 2 to t gear wheels, and, also, the small wheels which rotate the circulating pump and the armature of the magneto, can be easily detached by undoing a few nuts. A governor is fitted to the fore end of the inlet camshaft; it can be set according to requirements,. and operates a valve placed in a chamber on the upper portion of the carburetter.

The carburetter, as mentioned before, is patented. Referring to the diagram : A is the air inlet ; 13, an automatic valve, of piston form, which is raised upward as the engine. speed increases, and, in so doing, uncovers a port (0), thus admitting more air to the induction pipe; E is the float which works up and down in the chamber (R); the jet (G) is screwed into the bottom of the air chamber (D), and M is a valve for throttling the engine. The makers claim that this type of carburetter is most economical when in use, and that, owing to its simplicity, there is nothing to get out of order.

The pump for circulating the cooling water is bolted to, a bracket on the left-hand side of the engine, and it is driven by the wheel which actuates the exhaust camshaft. The water is forced along the pipes by the rotation of a solid metal disc, which is fitted with two nickel expanding wings. Two systems of ignition are supplied on each engine : Eisemann high-tension magneto, and the usual accumulators and a coil; the magneto has a simple means of testing the firing in each cylinder, by " wipers " held down by springs, but which can be lifted away when desired. The lubrication is on the splash system, and the oil falls upon the crankshaft bearings from three traps which are filled by the splashing of the cranks as they revolve. The price of the engine complete is 4'190. The workmanship and design are good, and should appeal to those who are making arrangements for the purchase of new stock.

The company does not confine its productions to commercial engines for road vehicles only, it also mann factures in large quantities motors for pleasure cars, launches, and for submarines. The makers claim that the " B and M " engines embody the

following advantages : great care has

been taken to keep the design as simple as possible, and intricate complications have been entirely eliminated, with the result that adjustments are rendered comparatively easy ; the workmanship is of the best, and all parts are interchangeable, and are machined to t,000th part of a millimetre, which ensures standardisation of all parts; another point of nuportance to omnibus owners. is that quick delivery is guaranteed.

It is the intention of the Company to place a bus chassis on the market shortly ; it will embody several new features, • and the design is the result of long and careful observations carried over a considerable period, increased comfort to

passengers, and econoThe patent carburetter, de rnical running are bescribed on the previous page.

ing specially studied.

The 35-4oh.p. model of engine is identical with the one that has been described, with the exception that the bore is uomin., whilst the piston stroke is isomm. The height from the centre of the crankshaft to the top of the cylinders 1.5 22 inches, as against 19 inches in the 24-3oh.p. model. Its length overall is nearly 43 inches, whilst the weight of the complete engine is 5511b. The price complete is ,C288, with magneto machine 4;318.

A large stock of the different classes of motors sold by the British Bariquand and Marre Company will be kept at 10, Poland Street, and intending purchasers can see any engine under running conditions by making an appointment.