A BRITISH RIGID-FRAME SIX-WHEELER.

Page 9

Page 10

If you've noticed an error in this article please click here to report it so we can fix it.

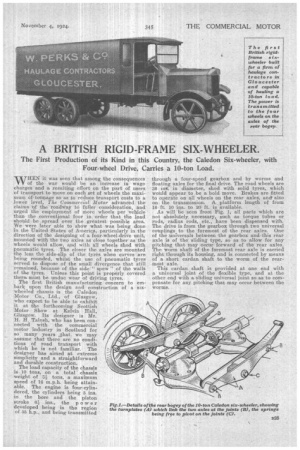

The First Production of its Kind in this Country, the Caledon Six-wheeler, with Four-wheel Drive, Carries a 10-ton Load.

WHEN it was seen that among. the consequences of the war would be an increase in wage charges and a resulting effort on the part of users of transport to move on each set of wheels the maxi• mum of tonnage so as to reduce transport costs to a lower level, The Commercial Motor advanced the claims nf the roadway to fuller consideration, and urged the employment of more wheels per vehicle than the conventional four in order that the load should be spread over the greatest possible area. We were later able to shOw what was being done in the United States of Ameriea, particularly in the direction of the designing of a four-wheel-drive unit, mounted with the two axles as close together as the wheels would allow, and with all wheels shod with pneumatic tyres. The closer the axles are mounted the less the side-slip of the tyres when curves are being rounded, whilst the use of pneumatic tyres served to dispose of the small divergence that still remained, because of the side spew" of the walls of the tyres. Unless this point is properly covered there. must be undue wear of driving tyres.

The first British manufacturing concern to embark upon the design and construction of a six wheeled chassis is the Caledon Motor Co., Ltd., of Glasgow, who expect to he able to exhibit it at the forthcoming Scottish Motor Show at Kelvin Hall, Glasgow. Its designer is Mr. H. H. Tainsh, who has been connected with the commercial motor industry in Scotland for so many years that we may _ assume that there are no conditions of road transport with which he is not familiar. The designer has aimed at extreme simplicity and a straightforward and durable construction.

The load capacity of the chassis is 10 tons, on a total chassis weight of 313, tons, a maximum speed of 16 m.p.h. being attainable. The engine is four-cylindered, the cylinders being 5 ins. in the bore and the piston stroke 61 ins., the p ower developed being in the region of 55 h.p., and being transmitted through a four-speed gearbox and by worms and floating axles for the final drive. The road wheels are 36 ins. in diameter, shod with solid tyres, which would appear to be a bold move. Brakes are fitted to operate on all wheels on the rear axles, and' also on the transmission. A platform length of from 16 ft. 10 ins. to 20 ft. is available.

As will be seen from Fig. 1, all parts which are not absolutely, necessary, such as torque tubes or rods, radius rods, etc., have been dispensed with. The drive is from the gearbox through two universal couplings to the foremost of the rear axles. One of the universals between the gearbox and.' this rear axle is of the sliding type, so as to allow for any pitching that may occur forward of the rear axles. The worm shaft of the foremost rear axle is carried right through its housing, and is connected by means of a short cardan shaft to the worm of the rearmost axle.

This cardan shaft is provided at one end with a universal joint of the flexible type, and at the other end with a sliding universal joint so as to compensate for any pitching that may occur between the worms. Lugs are formed on the axle casing, to which are connected the twin plates (A), which form links to keep the two axles the right distance apart. These links are pivotally connected to the axle casings by means of the joints (B). The springs lie between the twin plates (A) and are free to pivot on the joint (C). The springs are attached to the side-members of the frame at their foremost ends, and are shackled at their rear ends. By this arrangement it will be seen that all wheels are free to follow the contour of the road surface, no matter how uneven, and arc still able to preserve the equilibrium of the chassis.

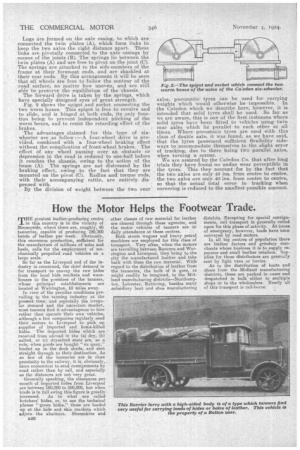

The forward drive is taken by the springs, which have specially designed eyes of great strength. Fig. 2 shows the spigot and socket connecting the two worm boxes. This spigot is free to revolve and to slide, and is hinged at both ends, its only function being to prevent independent pitching of the worm boxes, and to resist the retarding effect of the brakes.

The advantages claimed for this type of sixwheeler are as follow :—A four-wheel drive is provided, combined with a four-wheel braking effect without the complication of front-wheel brakes. The effect of any wheel passing over an obstacle or depression in the road is reduced to one-half before it reaches the chassis, owing to the action of the beam (A). The springs are not distressed by the braking effect, owing to the fact that they are mounted on the pivot (C). Radius and torque rods, with their accompanying rattle, are entirely dispensed with.

By the division of weight between the two rear axles, pneumatic tyres can be used for carrying weights which would otherwise be impossible. In the Caledon which we describe here, however, it is intended that solid tyres shall be used. So far as we are aware, this is one of the first instances where solid tyres have been fitted to vehicles using twin rear axles which lie parallel to each other at all times. Where pneumatic tyres are used with this class of double axle, it was found, as we have said, that the tyres possessed sufficient flexibility sideways to accommodate themselves to the slight error of tracking, due to there being two parallel axles, when turning a corner. We are assured by the Caledon Co. that after long trials they have found no undue wear perceptible in the tyres. This they account for by the fact that the two axles are only 40 ins, from centre to centre. the two axles are only 40 ins, from centre to centre, so that the actual total error in tracking when cornering is reduced to the smallest possible amount.