HINTS ON MAINTENANCE.

Page 30

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

571.—Some Useful Advice on the Foden Chain Drive.

The average life of the driving chain on a steam wagon in regular use is said by one of our contributors to be about four years but it is possible to get even longer service from this if careful attention be paid to its maintenance. On the other hand, if the chain be neglected the life will be shorter. The chain should be kept well supplied with oil and cleaned at least once a fortnight by applying paraffin oil on a stiff paint brush: After this lubricating oil should be run on to each link. Take the chain off the wagon every three months, place it in a tank of paraffin oil and allow it to remain there for half an hour. Then hang it up to drain and clean it thoroughly. After this place it in a bath of graphite and tallow which has been previously liquefied by heating. Allow it to remain there for an hour, so that the mixture can penetrate to the inner parts.

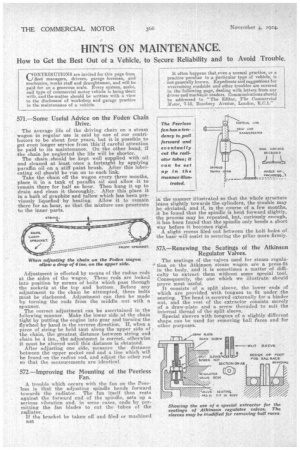

Adjustment is effected by means of the radius rods at the sides of the -wagon. These rods are locked into position by means of bolts which pass through the sockets at the top and bottom. Before any adjustment to the chain be attempted, these bolts must be slackened. Adjustment can then be made by turning the rods from the middle nut with a spanner.

The correct adjustment can be ascertained in the following manner. Make the lower side of the chain tight by putting the engine into gear and turning the flywheel by hand in the reverse direction: If, when a piece of string be held taut along the upper side of the chain, the greatest distance between string and chain be 4 ins., the adjustment is correct, otherwise it must be altered until this distance is obtained.

After adjusting one side, measure the distance between the upper socket end and a line which will be found on the radius rod, and adiust the other rod so that the measurements are identical.

572.—Improving the Mounting of the Peerless Fan.

A trouble which occurs with the fan on the Peerless is that the adjusting spindle bends forward towards the radiator. The fan itself then rests against the forward end of the spindle, sets up a serious vibration and, in some cases, ends by permitting the fan blades to cut the tubes of the radiator.

If the bracket be taken off and-filed or machined n46 in the manner illustrated so that the whole structure leans slightly towards the cylinders, the trouble may be obviated, and if, in the course of a few months, it be found that the spindle is bent forward slightly, the process may be repeated, but, curiously enough, it has been found that the spindle only bends a short way before it becomes rigid.. A slight recess filed out between the bolt holes of the base will assist in securing the pillar more firmly.

573.—Renewing the Seatings of the Atkinson Regulator Valves.

The seatings of the va,lves used for steam regulation on the Atkinson steam wagon are a press-fit in the body, and it is sometimes a matter of difficulty to extract them without some special tool. Consequently, the one which we illustrate should prove most useful.

It consists of a split sleeve, the lower ends of which are provided with tongues to fit under the seating. The head is screwed externally for a binder nut, and the rest of the extractor consists merely of a draw-plate and a screw threaded to suit the internal thread of the split sleeve. Special sleeves with tongues of a slightly different shape can be used for removing ball faces and for other purposes.