DEVELOPING THE PAGEFIELD REFUSE COLLECTOR.

Page 23

Page 24

If you've noticed an error in this article please click here to report it so we can fix it.

Details of the Pagefield System. The Increasing Use of the Plant. A Typical Report on its Application and the Saving Effected.

tlURING a recent visit to the works of Walker Bros.

(Wigan), Ltd., at Wigan we were interested to learn more regarding the developments which are Occurring in connection with the Pagefteld system, of refuse collection by means of a motor carrying unit and separate containers, which, when not actually on the motor unit, are hauled by horses.

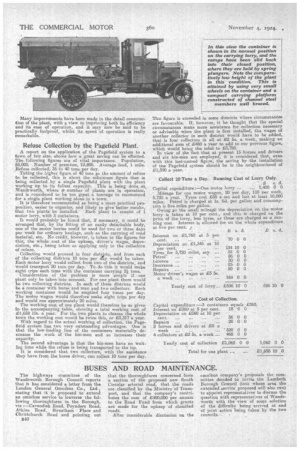

Each plant consists of one motor lorry; provided with suitable ramps, hauling and tipping gear, and three containers, two of which are constantly being loaded as they are moved from house to house by their horses, while the third is being conveyed on the lorry to the tip for uploading. Thus the bin-men have no waiting time, as an empty container is always available.

The system is becoming increasingly popular. It was first put into operation at Southport, and its use there has so mtended that the whole town is now Cleansed by this method. Complete plants have also been supplied to Wandsworth, Worthing, Bexhill and Halifax, and many interested inquiries are being received from other districts.

Immediately the municipal authorities in any district show themselves to be interested in the plant the town is " vetted " by representatives of the company and a report prepared. In view of the large amount of information contained in such a--report we include a typical one, which haR actually been sent out to one town. Many improvements have been made in the detail construction of the plant, with a view to imprfiving both its efficiency and its ease of operation, and it may now be maid to be practically foolproof, whilst its speed of operation is really remarkable.

Refuse Collection by the Pagefield Plant.

A report on the application of the Pagefield system to a town of fair size, shows how a great saving can be effected. The following figures are of vital importance. Population, 55,000. .Number of premises, 12,800. Average lead, 1 mile. Refuse collected, 35 to 40 tons per day.

Taking the higher figure of 40 tons as the amount of refuse to be collected, this is about the maximum figure that is being collected by a single Pagefield plant with the plant working -up to its fullest capacity. This is being done at Wandsworth, where number of Plants are in operation, and is considered to be too great a tonnage to recommend for a single plant working alone in a town.

It is therefore recommended as being a more practical proposition, easier to organize, and likely to give better results, that two plants be installed. Each plant to consist of 1 motor lorry, with 3 containers.

It would probably be found that, if necessary, it could be arranged that, by the fitting of an easily detachable body, one of the motor lorries could be used for two or three days per week for ordinary haulage, such as the carrying of road material, etc. No credit, however, is taken in the figures for this, the whole cost of the upkeep, driver's wages, depreciation, etc., being taken as applying only to the collection of refuse.

Collection would proceed in four districts, and from each of the collecting districts 10 tone per clly would he taken. Eaeh motor lorry would collect from two of the districts, and would transport 20 tons per day. To do this it would mate eight trips each time with the container carrying 4 tons. Consideration of the problem is move simple if one plant only be taken into account. For one plant there would be two collecting districts. In each of these districts would be a container with horse and man and to o collectors. Each working container would be emptied four times per day. The motor wagon would therefore make eight trips per day and would run approximately 20 miles. The working cost of one plant would therefore be as given irk the accompanying table, showing a total working cost of 21,658 10s. a year. For the two plants to cleanse the whole town the working cost would be twice this, or 23,317 a year. With regard to the actual working of collection, the Pagefield system has two very outstanding advantages. One is that the low-loading line of the containers materially decreases the work of the bin-men and so increases their capacity.

e second advantage is that the bin-men have no waiting time while the refuse is being transported to the tip. It is considered that two collectors, with the assistance they have from the horse driver, can collect 10 tons per day.

This figure is exceeded in some districts where circumstances are favourable. If however, it be thought that the special circumstances make more assistance for collection necessary or advisable when the plant is first installed, the wages of another collector in each district would have to be added, that is four collectors in all at 22 5s. a week, making an additional sum of 2460 a year to add to our previous figure, which wmild bring the total to 23,785. In view of the tact that at present 15 horses and drivers and • six bin-men are employed-, it is considered that, even with this last-named figure, the saving by the installation of the Pagefield system should be in the neighbourhood of 21,500 a year.