FROM TREE TRUN TIMBER STORE,

Page 16

Page 17

Page 18

Page 19

Page 20

If you've noticed an error in this article please click here to report it so we can fix it.

FROM THE very nature of the work, the removal of logs from the felling site to points where they can be sawn into a commercial size has always demanded cheap, and yet efficient, transportation. Contrary to popular belief, it is not always possible to fell a tree straight into a convenient river. As forest areas are exploited, distances from riverside steadily increase, until finally a point is reached where it would not be economical to cut down timber because of the high cost of hauling the logs to rivers or railways. The range of activity has been very materially increased, however, by the wide introduction of the motor lorry into the lumbering industry.

The vast equipment necessary for the transportation of this essential product, from the time each monarch of the forest falls to earth until its dismembered body contributes towards man's comfort and advancement in countless ways, makes it apparent that the motor lorry will come more than ever to the forefront as a definite economical force that demands a prominent place in the general scheme of forestry operation. Lorries are largely employed in loading and hauling green logs from the forests to the sawmill or rail sidings, for the construction of roads that make timber-cutting operations practicable in what would otherwise be inaccessible territory, for transporting material for constructing the dams that have to be built to provide sufficient water for log floating, for the hauling of green-cut timber from the sawmill to air-drying yards, kilns and sidings, for carrying timber from the drying yards to the planing mills, for delivering firewood, sawdust and shavings, for transporting hewed or sawed stock—railway sleepers, pit props, mine timber, posts, poles, bridge material, etc.—for the hauling of short timber stocks, and for the delivery of finished wood products.

In some sections of forestry work mules are used to skid logs to the nearest roadside, where lorries pick them up. Wherever practicable, however, lorries travel direct to the felling point to pick up loads. Lorries intended for use on lumbering operations should have plenty of road clearance in order to make travel easier over the rock-studded and rutted roads which are common to logging countries. Rugged construction, therefore, is essential. Engine cooling must also be very efficient, so that, no matter how long or hard the pull, the risk of overheating is averted. Naturally, heavy-duty lorries are best suited for the work. Vehicles of 3-ton and 5-ton capacity are widely popular, whilst in districts where particularly long and bulky logs are cut two-wheel trailers and semi-trailers are found of much advantage.

There is scope for the lighter lorry also. The majority of logging camps are remote from populated centres, and many of the necessities of life must be brought in from points which are considerable distances away. Two-ton and 15-cwt. vehicles are best suited for such work.

In the opinion of Mr. W. B. Greeley, of the United States Forestry Service, loading and unloading in practically all large lumber yards should be done by a tractor in conjunction with two of three semitrailers. Work of this character imposes unusually severe strains upon the final-drive mechanism of a lorry, and for this reason it is of the utmost importance that a particularly dependable type of vehicle, with a rugged form of final drive, be employed.

The chain-driven vehicle is considered to be the most efficient for timber haulage. Its rear axle being straight, greater road clearance is available, and it will also withstand more abuses. Even though the axle might be out of alignment, the chain still continues to function with no Serious reduction in efficiency.

Naturally, in the haulage of heavy logs the winch is playing an ever-increasing part in the loading and unloading of lorries. Before winch equipment was perfected it was the practice to yoke a number of oxen or horses on the opposite side of a lorry to which the logs to be loaded were placed. Then the log used to be drawn on to the body up a ramp by means of ropes. By this method three yoke of oxen and five men usually took from 60 minutes to 70 minutes to load a lorry with fourteen average-sized logs. A winch-equipped lorry can be loaded by two men in a similar manner and with a similar load in 20 minutes.

Another use to which winch-equipped lorries are now put is in connection with the skidding of logs out of ravines and other inaccessible places. In many other ways, too, lorries are performing the work previously done by locomotives and 'donkey engines. To-day progressive lumber concerns consider that their fleets are short of giving maximum efficiency if the ratio of winch-equipped lorries in their service is less than one to two.

To-day the demand for timber is greater than ever it -was. It is well, therefore, that, synchronizing with this demand, the motor lorry has been brought to such a high state of development that it can be economically used for hauling timber over distances that are impracticable by merely using bullock, elephant, or horse teams.

British manufacturers must devote considerable study to this subject if they are to keep pace with the ever-increasing demand for lorries for this work. Their opportunities for studying this subject firsthand, however, are limited, owing to the fact that lumbering, on the lines it is carried out in various other parts of the world, is unknown in this country.

As an indication of the importance with which some Colonial authorities regard the transportation of lumber products, it is only necessary to state that a few years ago a number of officials of the Indian Forestry Service was sent to America for the purpose of studying the most up-to-date and effective means of conducting logging operations. About the same time considerable experimental work was carried out in India with various types of mechanical vehicle in order to ascertain what was the best transport medium for economically performing work which the officials admitted to be of an undoubtedly arduous nature. Enough has been written to prove that the development of lumber operations will do much towards increasing the prosperity of many units of the Empire. There is not only a great need of timber for domestic use, but a great opportunity exists for developing a very important export trade. One instance might be quoted to support this contention. Iii an effort to encourage the use of Empiregrown lumber by the motor-body and carriagebuilding industry of Great Britain, the Imperial Institute Advisory Committee some time ago • induced the Institute of British Carriage and Automobile Manufacturers to carry out a series of . experiments with various Empire woods in place of American and other foreign hardwoods. The result of these experiments is now available, and the report in general is believed to prove that British motor body and carriage builders can, if they are willing to do so, restrict themselves entirely -to the use of Empire-grown lumber.

The Importance of the American Lumbering Industry.

• Without doubt, the lumbering industry reaches its

, highest level to-day in the• United States. In that country the forests are being cut down at such a rate that the question if reafforestation has become an acute one. Despite the fact that 36,000,000 saplings are being planted annually, timber is being felled much faster than it is growing. At the present rate of consumption the United States, instead of exporting thousands of millions of board feet of timber annually, must soon become an importer rather than an exporter.

To give an idea of the amount of timber used by the most progressive countries, it is only necessary to state that the annual wood consumption of the United States is 38,000,000,000 ft. of lumber. 100,000,000 railway sleepers, 6,500,000 cords of wood for the manufacture of paper, and 110,000,000 cords for fire lighting and maintenance. It might also be

added that the capital invested in the American lumber industry is 5,000,000,000 dollars, whilst the number of factoOes, sawmills, etc., engaged in the timber and kindred industries is 75,000, employing 1,350,000 workers. Nature's handicaps make logging difficult in the woods of the North-western United States. Yet this area must be regarded as possessing obstacles which are typical of those met with in many other parts of the world.

In the states of Washington, Oregon -and Idaho the various obstacles encountered have been successfully overcome by the intelligent use of motor lorries. Some of these vehicles are called upon to haul loss that range in size to as high as 7,200 ft superficial pert log, yet such logs have been successfully hauled up gradients of one in ten.

It is the custom of the lutriber companies in this region to start their donkey engines early in the spring, and to get the logs piled in preparation for removal by the time the land becomes firmer and drier in the summer. When the work of removal commences it is carried on, without interruption, by night as well as by day. Sometimes these logs -are piled to a height of 100 ft., but in a short time after the lorries start work the piles rapidly dwindle in height.

Frequent Floods Magnify Difficulties of Operation.

Many valuable timber tracks exist in the south of the United States. Because of frequent floods in the valley of the Mississippi and other rivers the roads are often soft and the going difficult, and this difficulty is aggravated by the long rainy season that extends over the winter months. Experience, how

ever, has proved that lorries are particularly adapted for working under these handicaps. Generally, 2-ton or 3-ton vehicles are used, although 5-ton models are preferred where the working ground is solid.

The average length of a journey undertaken by lorries engaged on lumber work in the United States is 16 miles for the return trip between timber and Much of the timber in the north-eastern states, with the exception of Maine, Minnesota, Wisconsin and one or two other heavily wooded states, lies in small and isolated patches. In most of these states waterways abound, so that ample facilities for logfloating to the mills are provided. In such areas lorries are used chiefly for hauling supplies to the camps, and in building roads as these camps are pushed farther and farther into the woods. The comparatively good roads in this area make 5-ton lorries with trailer attachments and winches the ideal equipment.

Logging Camps Isolated from Centres of Habitation.

In the woods of Maine there are 60 logging camps operated by the Great Northern Paper Co., of Bangor, Maine. In these camps, which are scattered through the northern part of the state close to the Canadian border,-4,000 men to 5,000 men are employed. For many years lorries have kept these camps supplied with food, clothes, tools and other

necessities.

This company use 28 lorries, all of one make. Two .5-ton models, equipped with tipping bodies, are used for building roads through new cutting fields. Nearly • 1,200 square miles of forest land have been opened • up by these vehicles. The Great Northern Paper

• Co. commenced using lorries in the spring of 1915. when nine 5-tonners were purchased to haul material for the construction of a dam 1,000 ft. long, SO ft. high, and strong enough to hold back 21,500 million gallons of water.

• This dam was built to regulate the river flow to permit log-floating to the mills. Although the lorries had .to travel 77 miles to and from three points of supply, these nine vehicles transported all the material required in less than two years. Everything • needed for the dam, including rolling stock for the industrial railway, was carried by the vehicles. The magnitude of this task will be realized when it is stated that 100,000 barrels of cement alone were used in the construction of the dam. Lorries are used efficiently for hauling logs 16 ft. long by 21 ft. in diameter along soft dirt roads in the swampy areas of south-west Georgia. The logs are first hauled to the edge of the swamp by teams of mules. There they are loaded on to lorries and carried to the railway 12 miles away. One method of loading the lorries in this region is by gravity along a slightly sloping runway, upon which the logs are rolled. Little labour is entailed in loading lorries in this way, as the end of the runway is level with the platform body of the lorry. The lorries in use in this area cover from 80 miles to 100.miles daily.

In the aggregate there are vast areas of timber inaccessible to railways which are standing ready to be felled, piled and transported to the sawmills. Owing to the remote areas in which logging operations are carried out, the question• of labour has always been a difficult ene. Naturally, therefore, the logging manager is predisposed to the utilization of as many labour-saving devices as possible. In the motor lorry he will readily recognize an ally of no mean proportions. The question of utilizing animal transport is rarely considered these days.

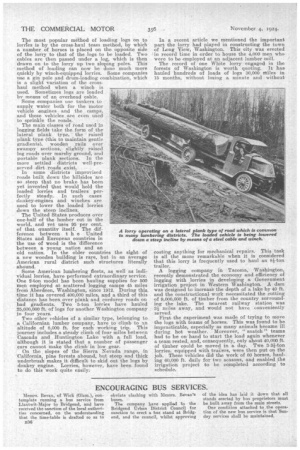

Lorries need roads, of course, but roads are more readily built than railways. In some instances existing roads can be used, together with an occasional short stretch of private road laid down to the loading point. In many cases, however, roads have to be built by the lumber companies and they take various forma. Where hard gravel ground is encountered they can be built readily and economically. In most logging districts, however, roads have to be drained off, banked, graded, and then laid with 4-in, planking or small poles. A .good road of this type, made with_ flattened poles 6 ins. to 14 ins. in diameter, can be built quickly and at small cost.

The Poptear Method of Loading Logs.

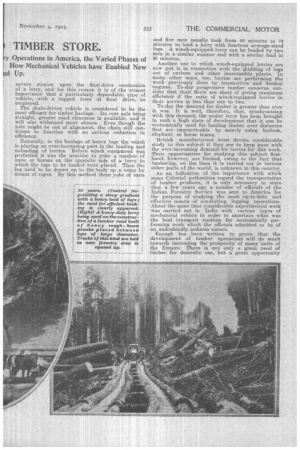

Now comes the second point where lorries have an advantage over railWays. Both lorries and trailer equipment can be secured much quicker than locomotives or railway trucks, but, more important still, the lorry provides a flexible means of .transportation. It can work ordinarily along a main road, and then in a few days a lateral road can be laid that will enable it to work in another section. Again, if the donkey engine has to be moved, it can he loaded on a lorry and put down where it is wanted. The most popular method of loading logs on to lorries is by the cross-haul team method, by which a number of horses is placed on the opposite side of the lorry to that of the logs to be loaded. Two cables are then passed under a log, which is then drawn on to the lorry up two sloping poles. This method of loading can now be done much more quickly by winch-equipped lorries. Some companies use a gin pole and drum-loading combination, which is a slight variation of the crosshaul method when a winch is used. Sometimes logs are loaded by means of an overhead cable.

Some companies use tankers to supply water both for the motor vehicle engines and the camps, and these vehicles are even used to sprinkle the roads.. The main classes of road used in logging fields take the form of the lateral plank type, the raised plank type (this to maintain gentle gradients), wooden rails over swampy sections, slightly raised log roads over marshy ground, and portable plank sections. In the more settled districts well-preserved dirt roads exist.

In some districts improvised roads built down the hillsides are so steep that no brake has been yet invented that would hold the loaded lorries and trailers perfectly steady. In such cases donkey-engines and winches are used to lower the loaded lorries down the steep inclines.

The United States produces over one-half of the lumber cut in the world, and vet uses 95 per cent. of that quantity itself. The differene,e between t h e United States and European countries in the use of wood is the difference between a young nation and an old nation. In the older countries the sight of a new wooden building is rare, but in an average American rural district such structures literally abound.

Some American lumbering fleets, as well as individual lorries, have performed extraordinary service. One 2-ton model has been hauling supplies for 500 men employed at scattered logging camps 45 miles from Aberdeen, Washington, since 1912. During this time it has covered 400,000 miles, and a third of this • distance has been over plank and corduroy roads on bad gradients. Two 5-ton lorries have hauled 25,000,000 ft. of logs for another Washington company in four years. Two other vehicles of a similar type, belonging to a Californian lumber company, have to climb to an altitude of 6,000 ft. for each working trip. This journey includes a steady climb of four miles between Cascada and Huntington Lake with a full load, although it is stated that a number of passenger cars cannot make the climb in low gear. On the _ slopes of the Sierra Nevada range, in California, pine forests abound, but steep and thick underbrush makes it difficult to skid out the logs by donkey engine. Lorries, however, have been found to do this work quite easily. In a recent article we mentioned the important part the lorry had played in constructing the town of Long view, Washington. This city was erected in record time in order to house the 4,000 men who were to be employed at an adjacent lumber mill. The record of one White lorry engaged in the forests of Washington is worth quoting. It has hauled hundreds of loads of logs 30,000 miles in 15 months, without losing a minute and without

costing anything for mechanical repairs. This task is all the more remarkable when it is considered that this lorry is frequently used to haul an Si-ton trailer.

A logging company in Tacoma, Washington, recently demonstrated the economy and efficiency of logging with lorries in developing a Government irrigation project in Western Washington. A darn was designed to increase the depth of a lake by 40 ft. and the constructional work necessitated the cutting of 9,000,000 ft. of timber from the country surrounding the lake. The nearest railway station was 3-i miles away, and would not have conveniently served.

First the experiment was made of trying to move the logs with teams of horses. This was found to be impracticable, especially as many animals became ill during hot weather. Moreover, " snatch" teams had to be on hand to start the load again whenever a team rested, and, consequently, only about 40,000 ft. of timber could be moved in a day. Two 3-3i-ton lorries, equipped with trailers, were then put on the job. These vehicles did the work of 60 horses, hauling 60,000 ft. daily for two seasons, and enabled the irrigation project to be completed according to schedule.