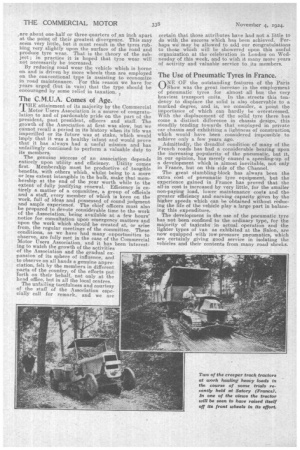

Production of a British Rigid-framed Six-wheeler.

Page 1

Page 2

If you've noticed an error in this article please click here to report it so we can fix it.

THE information which has been rendered available to designers and manufacturers on the question of the employment of mere than four wheels on a motor vehicle in order that the load should be spread over the largest area of contact with the ground has certainly been put to good use, for we find on every hand, 'not only in this country, but abroad, general agreement with the need for development upon the lines indicated. In America and in France greater consideration has been given to the use of the rigid frame with a four-wheeled rear bogey, constructed of two light rear-axle units, coupled so that they remain parallel and cannot pitch relatively to each other. They are, however, able to rock so that the wheels may follow any inequalities of the road surface.

On the other hand, British manufacturers, in their efforts to produce a vehicle capable of carrying a 10-ton load, have, up to the present, followed the excellent example set them by the originators of the articulated six-wheeler, which differs from the rigidframed vehicle with a four-wheeled rear bogey, in that the propulsion effort is concentrated on the wheels of the central axle and is not distributed over four wheels. Certain braking difficulties and manceuvring problems are set up in the articulated chassis,. which, whilst they are .capable of solution, are absent in the rigid-framed machine: For these reasons we have considered that the latter type was deserving of encouragement, time being the best test of the relative efficiency and, practicability of the two types.

We are glad, therefore, to welcome the effort put forward by a Scottish manufacturing concern to produce a 10-ton vehicle on six wheels, four of them. driving, and we look forward to a view of it and the opportunity for studying its design at the forthcoming Scottish Motor Show to be held at Glasgow later this month. We shall find added interest in the running of the vehicle in the fact that solid tyres are used, whereas American and French designers have relied upon the warping sideways of pneumatic tyres to get them out of the difficulty arising when the movement of the vehicle departs from a perfectly straight line, for on every curve, large Or small, the wheels on the rearmost axle of the bogey will endeavour to travel on a curve of a smaller radius than that described by the wheels on the parallel axle. The two tracks on a sharp curve are about one-half or three-quarters of an inch apart at the point of their greatest divergence. This may seem very little, but it must result in the tyres rubbing very slightly upon the surface of the road and produce tyre wear. That is the theory of the subject; in practice it is hoped that tyre wear will not necessarily be increased. By reducing road wear the vehicle which is borne on. and is driven by more wheels than are employed on the conventional type is assisting to economize in road maintenance. For this reason we have for years urged (but in vain) that the type should be encouraged by some relief in taxation.