The Latest Oilengined Track-laying Tractor

Page 40

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

IN any industrial work economy of operation is vital, and tractor users are now offered an International machine with an oil engine, which, of course, oilers opportunities materially to reduce running costs by way of a lower fuel-consumption rate and the use of a much cheaper fuel. The machine, which is now available at -.2,160. is handled by the International Harvester Co. of Great Britain, Ltd., 259, City Road, London, E.C.1, and is known as the Trac`TracTor, having a maximum engine output of 52 b.h.p.

The principal novelty lies in the power unit which is equipped with the usual auxiliaries of a petrol engine, as well as those enabling oil fuel to be used. This is done in order that the engine may be started by hand and automatically turned over to compression-ignition working. In this way, any separate starting apparatus is made superfluons.

At the forward end of the transmission casing, which, as in conventional tractor practice, forms the frame, is the four-cylindered engine of n ins. bore and 61, ins. stroke. In the cylinder head arerthree valves per cylinder, two of which are for ordinary inlet and exhaust piirposes, whilst the third is not operated by the camshaft hut by levers connected to the decompressor control. When these valves are off their seats much enlarged combustion spaces are provided, so that the compression ratio is low and is suitable for hand-starting and spark-ignition running.

On the near side of the crankcase is the fuel pump, which includes stainless-steel valves, valve seats and passages. All the parts are specially treated to prevent rust or corrosion, and the fuel filter is mounted directly on the injection pump, as is the governor.

On the offside of the engine is Prl International impulse-starter magnet) driven from the distribution gearing ; a clutch is included in the drive so that the magneto may remain idle when oil fuel is being used. Above the magneto is a carburetter which is connected to the induction manifold by a two-way valve ; the last-named allows the mixture to pass into the engine from the carburetter or air from au oil-type air filter, which operates during normal running. When the carburetter is not required its air intake may be closed by a spring-loaded trap so as to exclude all dust

The starting-up procedure is as follows :—the decompressor device is operated by a detachable handle ; this also puts out of action, at the same time, the fuel pump, and engages the magneto drive, switching over the air valve so as to bring into action the ,carburetter. The low compression allows the engine to be started by hand and it continues to run as a petrol unit for a pre-determined number of revolutions; this can be set by a control behind the fuel pump.

So soon as this warming-up period has expired the decompressor trip device is released and the compressionignition cycle starts. To achieve this full compression is restored, the carburetter and magneto are put out of action and the injectionpump trip is disconnected. All these functions are performed automatically, so that the operator merely has to set the engine for starting.

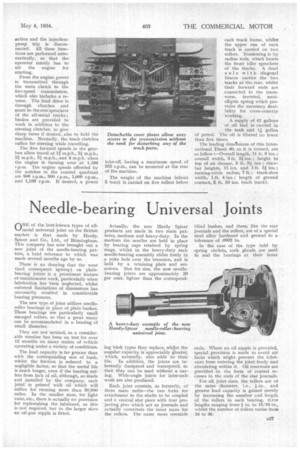

From the engine, power is transmitted through the main clutch to the five-speed transmission, which also includes a reverse. The final drive is through clutches and gears to the rear sprockets of the all-metaI tracks ; brakes are provided to work in addition to the steering clutches, to give sharp turns if desired, also to hold the machine. Normally, the track clutches suffice for steering while travelling.

The five forward -speeds in the gearbox allow travel at 11 m.p.h., 21 m.p.h., 21 m.p.h., 21 m.p.h., and 4 m.p.h. when the engine is turning over at 1,100 :span, The engine speeds afforded by the notches in the control quadrant are 800 r.p.m., 900 r.p.m., 1,000 r.p.m., and 1,100 r.p.m. If desired, a power

take-off, having a maximum speed of 535 r.p.m., can be mounted at the rear of the machine.

The weight of the machine (about 5 tons) is carried on five rollers below

each track frame, whilst the upper run of each track is carried on two rollers. Tensioning is by radius rods, which locate the front idler sprockets of the tracks. A dead axle wit h diagonal braces carries the two tracks at the rear, whilst their forward ends are connected to the transverse, inverted, semielliptic spring which provides the necessary flexibility for cross-country working.

A supply of 42 gallons of oil fuel is carried in the tank and 11 gallon of petrol. The oil is filtered no fewer than five times.

The leading dimensions of this International Diesel 40, as it is termed, are as follow :—Overall length, 11 ft. 9 ins. ; overall width, 5 ft. 3t ins. ; height to top of air cleaner, 5 ft. •5 ins.; drawbar heights, 11 ins. and 1 ft. 51 ins. ; turning-circle radius, 1 ft. ; track-shoe width, 1 ft. 4 ins. ; length of ground contact, 5 ft. 10 ins. (each track).