A New Steam Wagon.

Page 6

Page 7

Page 8

If you've noticed an error in this article please click here to report it so we can fix it.

Messrs. Bretherton and Bryan's Vehicle is one of several New Corners.

It was naturally to be expected that with the appearance of the Heavy Motor Car Order legalising motor wagons of 5-ton tare a number of new designs should be brought forward, and that fresh names should make their appearance in the industry. Several new motor wagons made their bow to the public at the Agricultural Hall Show, but one or two engineers were unable to get their vehicles ready in time for c:Nhibition, and did not care to spoil their debut by ill-considered haste. Messrs. Bretherton and Bryan, of Grange Works, Willesden Green, were of this number, and their first lorry will be running in regular service a fortnight hence. To those who have watched the progress of mechaMeal transport in London, Mr. Bretherton's name is well known, for he was running two Mann wagons when most of us were still sitting on the fence and when every horse looked on motor vehicles as infernal machines. His partner, Mr. L. C. Bryan, was apprenticed to Messrs. Davey, Paxman and Co., and afterwards spent some time at the Napier works, though he has always recognised that steam is the power for heavy loads. As was to be expected, Mr. Bretherton has endeavoured, in designing this new motor wagon, to avoid the proved drawbacks of the earlier types, and generally to adhere to such portions of traction engine design as have, under the natural selection of accumulated experience, proved their fitness by survival in motor-wagon practice. In spite of this, his motor wagon has none of the clumsiness of the traction engine, as will be noticed from the general view (Fig. J).

The boiler is of the ordinary locomotive type, with 39 smoke tubes of Qin. in diameter, but is fired from the top through a vertical tube. It will be seen from the section of the boiler (Fig. 2) that this firing tube immensely strengthens the fire-box crown and obviates all the usual expensive and clumsy staying. This saves weight in addition to cost, and at the same time the space round this vertical tube makes a very efficient steam dome, ensuring that only dry steam shall be supplied to the engine. A door is provided on the side of the fire-box shell, below the footplate. for cleaning out clinker or drawing the fire. The working pressure is ISolb. to zoolb. per sq. in., and there are 75sq. ft. of healing surface. This is as much as is provided in many motor-wagon boilers of lower efficiency. The grate area is 3.954. ft., which is sufficient both to relieve the driver from incessant attention to his fire and also to ensure a regular temperature in the fire box, resulting in an increased life of the boiler.

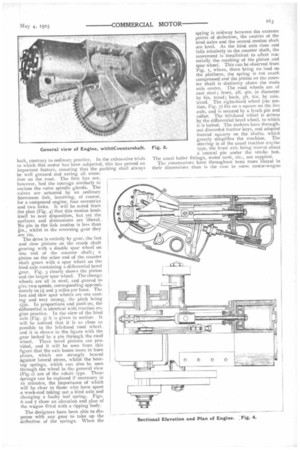

The et gine is placed under the wagon platform, and is of the horizontal compound type, with cylinders 5in. and 71in. in diameter by gin. stroke. A general view of the engine is shown in Fig. 3, and a sectional plan and elevation in Fig. 4. Its compactness is at once apparent, and it will be noted that the steam chest is placed underneath the cylinders. This saves any necessity for cylinder drain cocks, as the valves leave the face when standing, and any water that accumulates can be drawn off by one cock on the steam chest cover. All the engine motion is enclosed in an oil bath, the only opening to which is on the top. This, whilst allowing good access for examination and adjustment, provides that little oil can escape and be wasted. It will be noted that the piston rod glands are in the oil

bath, contrary to ordinary practice. In the exhaustive trials to which this motor has been subjected, this has proved an important feature, ensuring that the packing shall always be well greased and saving all attention on the road. The firm has not, however, had the courage similarly to enclose the valve spindle glands. The valves are actuated by an ordinary Stevenson link, involving, of course, for a compound engine, four eccentrics and two links. It will be noted from the plan (Fig. 4) that this motion lends itself to neat disposition, but yet the surfaces and dimensions are liberal. No pin in the link motion is less than din., whilst in the reversing gear they are tin.

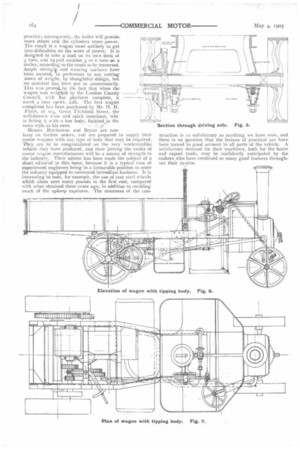

The drive is entirely by gear, the fast and slow pinions on the crank shaft gearing with a double spur wheel on one end of the counter shaft; a pinion on the o:her end of the counter shaft gears with a spur wheel on the hind axle containing a differential bevel gear. Fig. 3 clearly shows the pinion and the larger spur wheel. The change wheels are all in steel, and geared to give two speeds, corresponding approximately to.2i and 5 miles per hour. The fast and slow spur wheels are one casting and very strong, the pitch being In proportions and posit:on, the differential is identical with traction engine practice. In the view of the hind axle (Fig. 5) it is given in section. It will be noticed that it is as close as possible to the left-hand road wheel, and it is shown in the figure with the gear locked by a pin through the road wheel. Three bevel pinions are provided, and it will be seen from this figure that the axle boxes move in horn plates, which are strongly braced against lateral stress, whilst the bearing springs, which can also be seen through the wheel in the general view (Fig. u) are of the volute type. These springs can be replaced if necessary in io minutes, the importance of which will be clear to those who have spent a week-end taking out a hind axle and changing a faulty leaf spring. Figs. 41 and 7 show an elevation and plan of the wagon fitted with a 'ripping body.

The designers have been able to dispense with any gear to take up the .deflection of the springs. When the spring is midway between the extreme points of deflection, the centres of the nind axles and the second motion shaft are level. As the hind axle rises and falls relatively to the counter shaft, the movement is insufficient to affect materially the meshing of the pinion and spur wheel. This can be observed from Fig. 1, where, there being no load on the platform, the spring is not much compressed and the pinion on the counter shaft is distinctiy above the main axle centre. The road wheels are of cast steel ; front, 2ft. gin. in diameter by 6in. tread; back, 3ft. 6in. by loin. tread. The right-hand wheel (see section, Fig. 7) fits on a square on the live axle, and is secured by a lynch pin and collar. The left-hand wheel is driven by the differential bevel wheel, to which it is bolted. The makers have throughout discarded feather keys, and adopted instead squares on the shafts, which greatly simplifies the machine. The

steering is of the usual traction en g Inc

Fig. 3. type, the front axle being moved about a central pin under the smoke box. The usual boiler fittings, water tank, etc., are supplied. The constructors have throughout been more liberal in their dimensions than is the case in sonic motor-wagon

practice; consequently, the boiler will provide more steam and he cylinders more power. The result is a wagon most unlikely to get into difficulties on the score of power. It is designed to take a load on its own deck of 5 tons, and tq pull another 5 or 6 tons on a trailer, accordingto the roads to be traversed. Ample strengtp and wearing surfaces have been secured, 'in preference to any cutting down of weight, by thoughtful design, but no material has been put in unnecessarily. This was proved., by the fact that when the wagon was weig-hed by the London County Council, ‘yit-h fiat platform complete, it tared 4 tons igewt..221b. The first wagon completed has been purchased by Mr. H. H. Finch, of 103, Great Titchlield Street, the -well-known wine and spirit merchant, whc is fitting it with a box body, finished in the same style as his vans.

Messrs. Brettlerton and Bryan are now 'busy on further orders, and are prepared to supply their !motor wagons with any type of body that may be required. They are to be congratulated on the very workmanlike vehicle they have produced, and their joining the ranks of motor wagon manufacturer will be a source of strength to the industry,. Their advent has been made the subject of a short editorial in this issue, because it is a typical case of experienced engineers being in a favourable position to enter the industry equipped to command immediate business. It is interesting to note, for example, the use °f east steel wheels which alone save many pounds in the first cost, compared with what obtained three years ago, in addition to avoiding much of the upkeep expenses. The stoutness of the con

struction is as satisfactory as anything we have seen, and there is no question that the lessons of practical use have been turned to good account in all parts of the vehicle. A satisfactory demand for their machines, both for the home and export trade, may be confidently anticipated by the makers who have combined so many good features throughout their system.