MAKING BEST USE OF THE FORD.

Page 20

If you've noticed an error in this article please click here to report it so we can fix it.

Valuable Advice on Every Phase of Ford Transport, Which Will Appeal to the Owner, Driver and Repairer.

IN THIS series of hints concerning the Ford light chassis and ton truck wherever they are employed for commercial purposes, we endeavour to deal with the subject from every view-point, so that the advice given will appeal to the owner, driver, maintenance engineer, or mechanic. We shall welcome for inclusion among the hints those which have proved of value to individual users, and will make suitable remuneration for any published. What we desire are the results of practice. Readers are recommended to obtain the original " Book of the Ford," which constitutes a complete manual dealing with the Ford car, the van and the truck. 2s. 9d.post free from the offices of this journal.

173.—A Piston-ring Tip.

A good many Ford piston rings are tapered from one side to the other, as indicated in the sketch ; the diameter at one side of the ring is very slightly larger than that at the other. Knowledge of this is important, since, if the rings, be fitted in the piston the wrong way up,'they may tend to exaggerate any oiling-up difficulties which may arise. The top ring is the most important one, and care should be taken when replacing the rings that the larger diameter is the lower. It then acts as a scraper ring and prevents excess Of oil from getting into the cylinder head.

174.—Oiling the Valve Stems and Tappets.

One of our readers had some difficulty in thoroughly oiling: the valve stems and tappets of hie Ford engine, Which sometimes set up an objectionable squeaking. He finally overcame the trouble by adding, once a week, rather less than a gill of engine oil to a full tank of petrol. He finds that the Ford carburetter sucks this oil through to the valve sterns, where it is Ceposited, by, turning the engine over a few times by hand and holding the primer right out. Restates that this oiling keeps the engine much more, si le n t.

175.—Abstracting a Washer from the Transmission Casing. It sometimes happens, in the course of effecting some minor repair, that a nut or washer is dropped into the transmission casing, where it is very difficult of access. Indeed; more often than not, such a catastrophe involves the mechanic in :removing the whole engine and dismantling it, in order to extract the obstacle and eliminate the risk of serious damage which might be brought about if it were left there.

A useful aid in such circumstances is a small toy magnet, such as can be purchased anywhere for a few B3G

pence. If this be tied to the magneto on the flywheel, in suCh a manner that it gently serapes the interior of the transmission case as the flywheel is revolved, it will more often than not pick up the lost part and bring it to the top, when it can easily be removed.

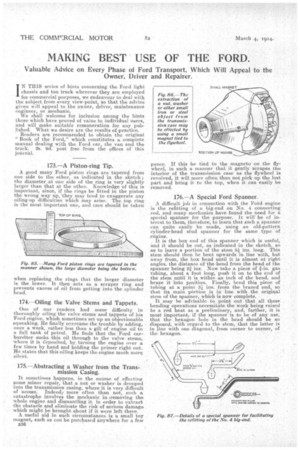

176.--A Special Ford Spanner.

A difficult job in connection with the Foid engine is the refitting of a big-end on No. 4 connecting rod, and many mechanics, have found the need for a special spanner for the pu-rpose. It will be of interest to them, therefore, to learn that such a spanner can quite easily be made, using an old-pattern cylinder-head stud spanner for the same . type of cngine. it is the box end of this spanner which is useful, and it should be cut, as indicated in the sketch, so as to leave a portion of the stem 54 ins. long. This stem should then be bent upwards in line with, but away from, the box head until it is almost at right angles, the distance of the .bend from the head of the spanner being 2i ins. Now take a piece of --in. gas tubing, about a foot long, push it on to the end of the stem until it is withinan inch of the bend, and braze it into position. Finally, bend this piece of tubing at apoint 3'2ins, from the brazed end, so that its main portion is in line with the original stern of the spanner, which is now complete. It may be advisable to point out that all these bending operations necessitate the work being raised to a red heat as a preliminary, and. further, it is most important, if the spanner is to be of any use, that the hexagon hole in the head should be so disposed, with regard to the stem, that the latter is in line with one diagonal, from corner to corner, of the hexagon.