CONVEYANCE OF MILK IN BULK.

Page 13

Page 14

If you've noticed an error in this article please click here to report it so we can fix it.

The Reasons Why Little Progress is Being Made in this Country with a Method which Operates Successfully in America.

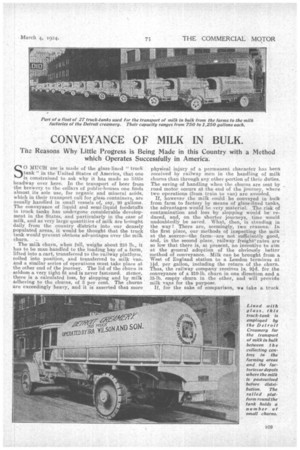

SO MUCH use is made of the glass-lined " truck tank" in the United States of America, that one is constrained to ask why it has made so little headway over here; In the transport of beer from the brewery to the cellars of public-houses one finds almost its -sole use, for organic and mineral acids, which in their transport call for glass containers, are usually handled in small vessels of, say, 20 gallons. The conveyance of liquid and semi-liquid foodstuffs in truck tanks has undergone considerable development in the States, and particularly in the case of milk, and as very large quantities of milk are brought daily from the country districts into our densely populated areas, it would be thought that the truck tank would present obvious advantages over the milk

churn. .

The milk churn, when full, weighs about 210 lb., it has to be man-handled to the loading bay of a farm, lifted into a cart, transferred to the railway platfqrni, rolled into position, and transferred to milk van, and a similar series of operations must take place at the other end of the journey. The lid of the churn is seldom a very tight fit and is never fastened. _deuce, there is a calculated loss, by slopping and by milk . adhering to the churns, of 3 per cent. The churns are exceedingly heavy, and it is asserted that more physical injury of a permanent character has been received by railway men in the handling of milk churns than through any other portion of their duties. The saving of handling when the churns are sent by road motor occurs at the end of the journey, where two operations (from train to van) are avoided.

If, however the milk could be conveyed in bulk from farm to factory by means of glass-lined tanks, the advantages would be very material. The risk of contamination and loss by slopping would be• reduced, and, on the shorter journeys, time would undoubtedly be saved. What, then, is standing in the way2 There are, seemingly, two reasons. In the first place, our methods of inspecting the milk at the source—the farm—are not sufficiently good, and, in the second place, railway freight'rates are so low that there is, at present, no incentive to aim at the general adoption of the obviously better method of conveyance. Milk can be brought from a West of England station to a London terminus at lid, per gallon, including the return of the churn. Thus, the railway company receives is. 9id. for the conveyance of a 210-1b. churn in one direction and a 35-lb. empty churn in the other, and will provide milk vatns for the purpose.

If, for the sake of comparison, .we take a truck

tank with a capacity of 1,000 gallons of milk, we should have a gross load of 10,300 lb. weight of milk, whilst the tank and its fittings would weigh, say, 2,500 lb., or 12,800 lb in all, equal to about. 5 tons 14 cwt. The freight on 1,000 gallons of milk at lid. per gallon would amount to-25 45., which would not be a sufficient return on a double journey. (for it is, obviously, a one-way load) of, say, 100 miles to 130 miles each way. Thus, the freight rate would need to be increased, but justification for this would be admitted, in view of the better qUality` of the milk when it reached the factory and the saving of handling. This is the experience in the States, where often the truck tank has to meet competition from both steam-hauled and electric railway services, and meets it quite successfullY.

We are thus thrown back upon the real reason— the lack of equipment for dealing with the milk at the country terminals and the methods of inspection. If milk is to be transported in bulk, every churnful poured into the truck tank must be above suspicion; or the whole tankful may be spoiled. The milk may be stale, thberculous, or deficient in butter fat, it may be overheated, watered, or unclean. The churn in which it is conveyed may have escaped prior cleansing. If the milk is taken to the factory in the original churn, any defect discovered on the inspection and under tests there imposed can he laid at the door of the supplier, and this acts as a good check upon the farmer.

But were the truck fanks to proceed from farm to farm and to take in the milk offered at each, the door would be opened to abuse, and, to prevent this, a proper collecting system would need to be laid down. The most practical way would be to erect a collecting station for each area, to equip it with plant for testing, cooling, and transferring from farm churn to tank. The matter of cooling is highly important, for a churn of overheated milk might spoil the whole of the bulked load. Each churn load of milk, therefore, must, as received, be tested for taste and smell, its temperature must be noted, and the milk passed through a cooler if necessary and its butter fat content be recorded. At the factory it is cleaned, pasteurized, and" bottled, and all milk in excess of demand is condensed, or made into butter, cheese, or milk powder.. .

The concern which has had most to do with the production of vessels for the treatment and conveyance of milk is the Enamelled Metal Products Corporation, Ltd., of '56,"Kingeway, London, W.0.2., a branch of the Pfaudler Co., of Rochester, N.Y., U.S.A. For many years the latter company concentrated upon the brewing industry of the States; but one of the results of prohibition has been'toplace the products of the Pfaudler works at the disposal of other industries,. and it is interesting to know that to-day over a hundred different industries use the Pfaudler glass-lined steel receptacles. The steel has to-be up to a certain specification, and the welding of the joints has to be done, not merely for strength, but for absolute smoothness of surface. The glass enamel is extremely thin—in contradistinction to other systems of lining where a thick layer is employed.

It is the experience of the Enamelled Metal Products Corporation that big units are not necessary in transport. Thus, for milk, a 6-ton Vehicle may be regarded aa the maximum. This would accommodate a tank having a capacity of 1,250 gallons, and two other suitable sizes would be for 750 gallons and 1,000 gallons each. In the States, where high temperatures over long periods are experienced, an outer shell with insulation between it and the container; would be advisable, but over here a tarpaulin over the tank would be amply sufficient in hot weather, as a rise of 1 to 2 degrees Fahrenheit per hour would be the maximum, whereas, with churns, the temperature on an average railway journey will rise from 10 to 20 degrees.