CUTTING THE SPARES BILL ON T]

Page 26

Page 27

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

MORRIS-COMMERCIAL 3-1-TON NER

WITI-I new parts in short supply; 'coupled with the

bigger demand imposed on road transport by war conditions, preventive maintenance assumes considerable importance. it es not sufficient to oil or grease a part because it looks dry, or has commenced to utter protests throygh lack of lubrication. Neither will haphazard tightening-up of a loose nut cut much ice if reliability be desired. Systematic maintenance alone can prevent breakages. and thorough servicing, against speedometer and log-book readings, is the basis of running a successful transport fleet As the maintenance of the Morris-Commercial CV II/40 .model conforms, with but few deviations, to standard -practice, the servicing details that have to he carried out daily, and at certain intervals, are straightforward.

Besides the daily inspection of the petrol, water and oil levels, the tyres should he kept inflated at the pressure recommended for the maximum load. To make sure that the hydraulic_ brakes are in order, an application of the brake pedal should give a feeling of solid resistance. Also check all *heel nuts for tightness.

In the case of the twin rear wheels, if more than one out has worked loose it is advisable to jack up the axle and slacken off all nuts, retightening in diametrically opposed sequence so that the wheels can seat themselves on the faces of the studs and washers.

Assuming that the vehicle has had its first servicing. the followiug operations should be carried out after every 500 miles' running After removing the caked mud from the chassis and coachwork, the oil-gun, filled with soft

grease, should be applied to the nipples of the frontaxle pivots, all spring shackles and anchorage bearings: there are 14 nipples in all. At every 1,000 miles, in addition to the servicing described, it will become necessary to check the oil levels in the gearbox and back axle, and fill to the correct level.

Engine attention devolves upon setting the inlet valves. at .004 in. and the exhaust valves at .018 in. when hot, an operation which is completed, after rotating the engine only two revolutions, by observing the following table:— The hall bearings carrying the fan will be adequately lubricated" if the oil-gun be. applied to the nipple. The ignition-distributor oiler should also ,receive a few drops of light machine oil, a single drop sufficing for the contact-breaker pivot. Also, do not forget to oil the driving end of the dynamo, whilst a little distilled water will probably be required by the battery.

The road springs, after being scraped clean of mud, may be brushed with used engine oil, thinned with a little paraffin. The nipples on the steering track-rod and the drag link should be greased (four in all), and the steering box filled with oil by means of the oil-gun. There is an oil hole provided just below the steering wheel; two drops of engine oil in this will lubricate the bush in the head of the calcium. Before dispensing with the can, oil the clutch and brake-control joints. Finally, with the grease gun, go over the rear brake operating cross-shaft nipples, and the Ilardy-Spicer universal joint on the propeller shaft. 'There is also a nipple mounted amidships, on the near sick of the chassis; this communicates with the propeller-shaft centre-bearing, by means of a pipe line, and "one shot with the oil-gun is called for.

In addition to the features already mentioned, wisdom dictates that the oil should be drained from the engine at about 3,000 miles, and the cartridge of the external filter unit be cleaned and emptied at the same time. A few drops of light machine oil should be dropped on the automatic advance and retard mechanism of the ignition distributor, the Bakelite rotof arm being first removed, It is not necessary to remove the screw exposed to view by this operation, as clearance has been provided for the oil to reach its destination.

Quite a number of additional items appeas on the agenda when 5,000 miles have been covered, and the driver may be pardoned if he takes a little longer than usual over his maintenance.

As the radiator, with usage, becomes coated internally with a slimy rust deposit, it should he flushed out by means of a hose for five minutes when the engine is hot. Also, when warm, drain the gearbox and rear axle and flush with ckaft flushing oil, replenishing the gearbox with 3,1 pints, and the axle'veitit 21 pints ot the gear oil recommended bythe makers Next, test the clutch pedal for free movement, in. of

free movement being essential. This operation is carried out simply by slackening • the nut securing the quadrant to the pedal, and moving the quadrant back' one or two serrations.

If there be too much play in the brake pedal, jack up the wheels and tighten the brake adjusting screws until the shoes just bind, then unscrew until the wheel can be rotated without any appreciable drag being felt. The travel in the brake pedal thus being much reduced, it is essential that there be On. free movement in the pedal before the operation of the master-cylinder piston can be felt. The clearance should be obtained by releasing the adjusting lock-nut, R, so that the piston rod, Q, may be screwed as necessary. The adjustable stop, H, is pro , vided solely for the purpose of preventing the pedal from • coming into contact with the toe plate. These points are shown in an accompanying diagram.

• Top-up the master reservoir with genuine Lockheed brake fluid No. 5, to make up for loss due to slight evaporation. It must be stressed that the use of any other kind of fluid for this purpose is dangerous as it destroys the rubber components of the 'hydraulic-braking system, causing swelling and the blocking up of the by-pass ports. If the .pedal, on being depressed, has a spongy feeling, and not one of solid resistance, then air has entered the system and bleeding becomes necessary. For thissoperation use the rubber tube and union .provided in the tool

kit, and a clean glass jar. Keep on replenishing the master reservoir with fluid until no more bubbles are being pumped into the jar when operating the brake pedal as you would a foot pump. Quite candidly, bleeding is seldom called for qnless the leyel in the reservoir has been allowed to get too low as a result of negligence or from other causes.

Jack up the wheels, check front-wheel track alignment—. whish should be in. less at the front than at the rearand%djust toe-in, if necessary,gby slackening oil the pinch bolts at each end of the track rod, and turning the rod in such a direction that, its effective length is shortened or lengthened as may be found necessary.

Before taking off the front wheels, check for bearing play. If adjustment be necessary, remove hub caps and split pins, and with the requisite hill) spanner tighten to the point where there is, only perceptible play—just sufficient to give a maxirnuni "rock" of i in. at the periphery of the wheel. Wheel shake, and consequent tyre scrub, are thus removed.

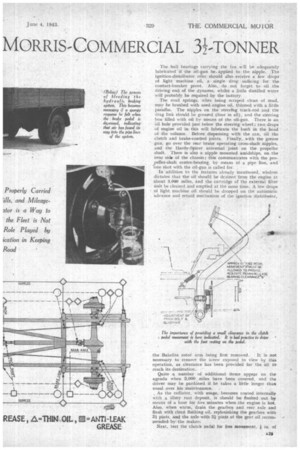

In the case of the twin rear Wheels, the driving shaft must be withdrawn, as shown in the illustration, before the large slotted nut, retaining the bearings, is exposed.

Removal of the road wheels is recommended. As the nuts on the near side of the vehicle have left-hand threads, they must be turned in the opposite direction to normal. Thoroughly clean the hub. surfaces and studs, wiping over with an oily rag to prevent rusting up. In replacing the hub caps. pack them with grease, and the wheel nuts should be tightened according to the procedure described earlier.

With regard to Ae worm-and-sector-type steering gear, the end play of the worm may be tested by alternately pushing and pulling the steering wheel. If there be any appreciable movement, the bottom cover of the steering box may be removed and the end play rectified by taking out a shim. Bad steering can also be caused by loose roadspring holding-down bolts. It is essential to see that all chassis and body bolts are tight.

• Concerning the engine, remove and clean the carburetter

petrol filter, also the Autovac inlet filter. Any sediment in the outer chamber may be removed by partially draining off the petrol. Fan-belt tension is correct when the belt can be squeezed together to about 1 ins, at the centre, Slackness may be taken up by adjusting. the halves of the

driven pulley. This is done by slackening off the locking nut by means of a tommy bar, disengaging the locking tab, .aid using the bar to tighten the adjustable half of the pulley lay the holes provided. Replace the tab in the nearest slot before tightening the lock-nut.

In addition to the usual lubrication of the ignition distributor, adjust the contact-breaker contacts to the thickness of the gauge provided, which is about 12 thousandths of an inch. The plugs, likewise, should be set after being cleaned in a sand blast,, the gaps being adjusted to 22 thousandths of an inch. Always adjust the side electrodes; never try to bend the centre electrode as this cracks the porcelain insulation located in he body of the plug.

In conclusion, at 10,000 miles, some fleet owners insist on having the engine decarbonized and the valves ground in. This is a good thing, as engine efficiency cannot be maintained on pitted exhaust-valve seatings. Whether this• operation be delayed for another 2,000 or 3,000 miles rests with the individual owner, but delay often means neglect, and maintenance, to be really efficient, should be worked out on a strict mileage basis.